YAG multi-beam light splitting gradual-change type light path negative feedback control system

A control system and gradual change technology, applied in the direction of manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems affecting the normal operation of 5G communication, high cost, etc., achieve fast and convenient debugging, simple use, and ensure welding stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

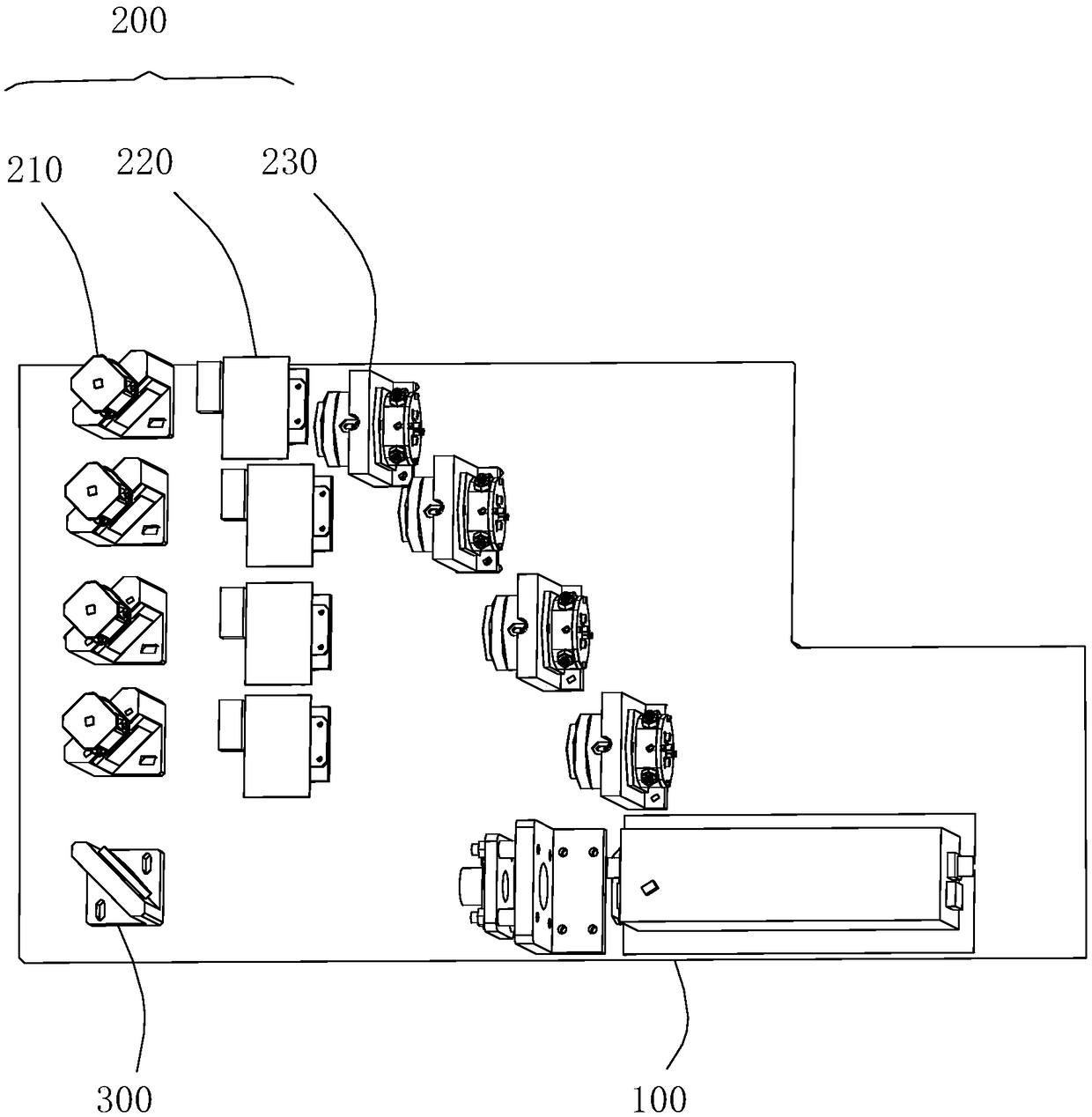

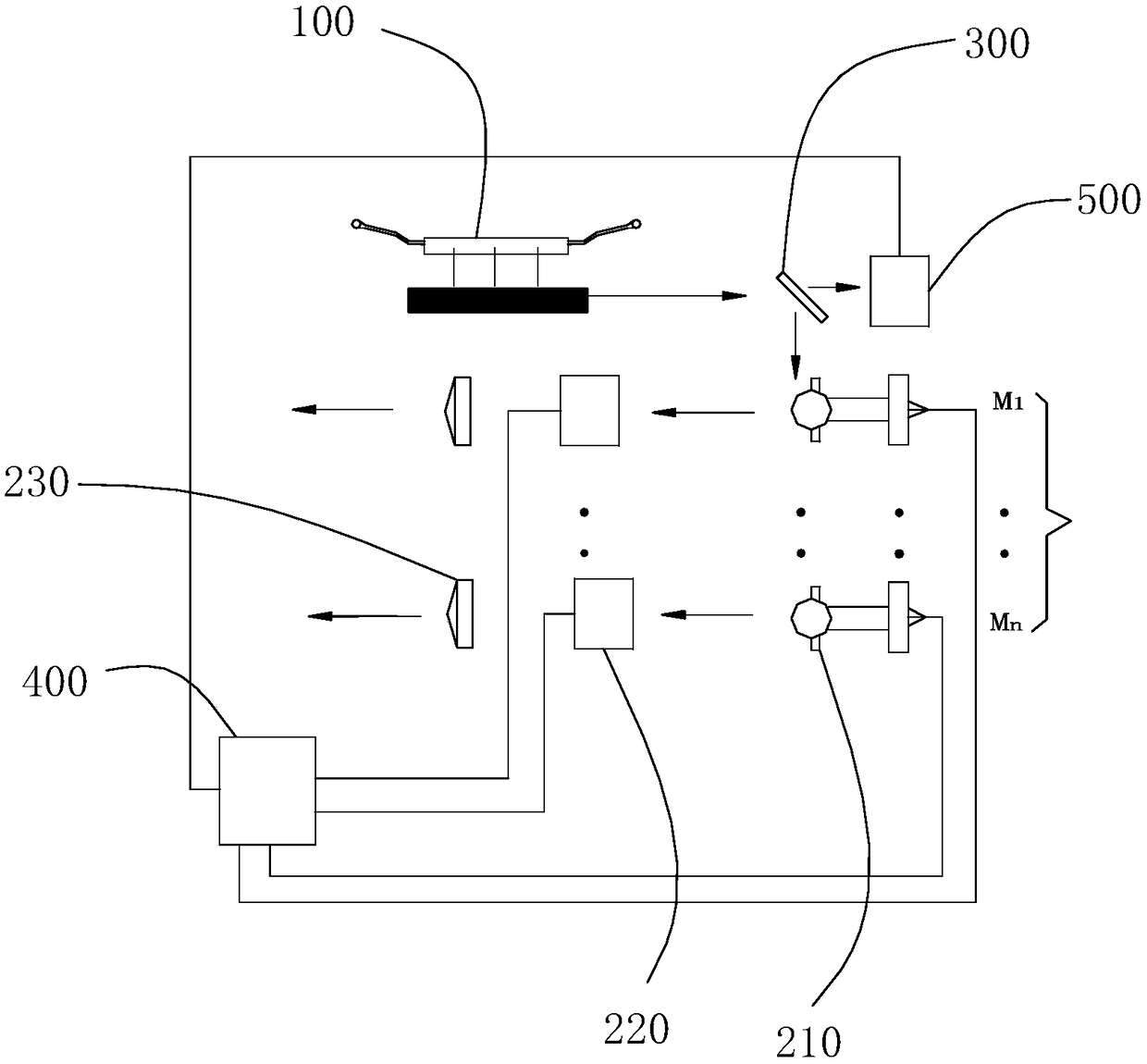

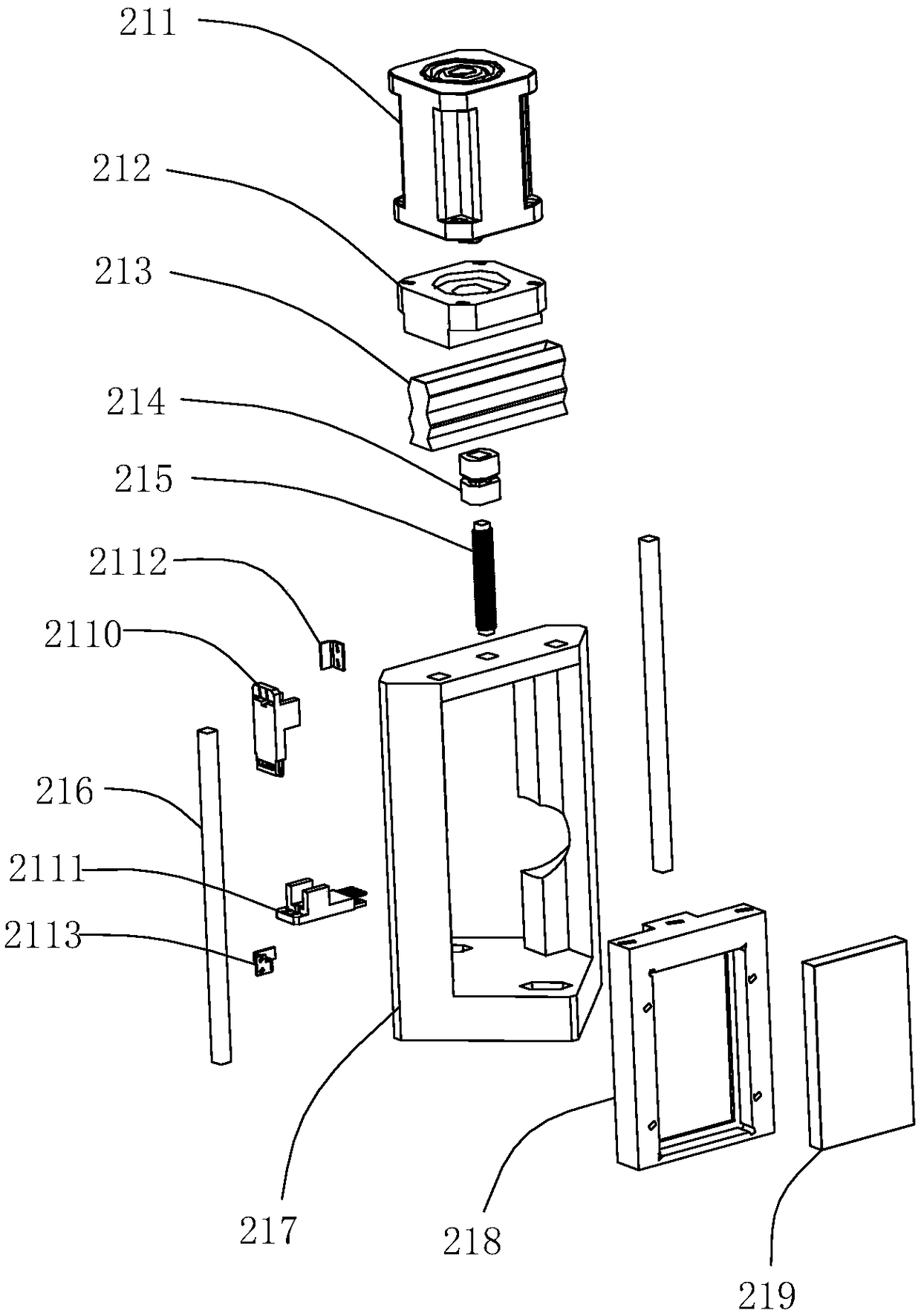

[0017] A YAG multi-beam splitting and gradual optical path negative feedback control system proposed in this embodiment, such as Figure 1 to Figure 4 As shown, it includes: a laser 100, at least one coupling optical path assembly 200, a quartz mirror 300, and a control device 400; each coupling optical path assembly 200 includes a gradual optical splitting device 210, a first energy negative feedback device 220 and a laser coupler 230, Quartz reflector 300 is set at an angle of 45 degrees to the light beam of laser 100, and the gradient beam splitter 210 is set at a 45-degree angle to the refracted beam of quartz reflector 300. The first energy negative feedback device 220 and laser coupler 230 are connected to the gradient beam splitter The refracted beam of the device 210 is located on a straight line, and the first energy negative feedback device 220 is located between the laser coupler 230 and the gradual optical splitting device 210; the first energy negative feedback dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com