Guide pipe frame closing process, supporting frame and supporting assembly

A technology for supporting components and jackets, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as increasing difficulty, difficulty in meeting construction conditions for ordinary wharves, and complex construction processes, reducing handling difficulty and avoiding handling distances. Too far, the effect of improving the transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

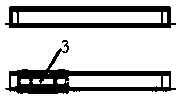

Image

Examples

Embodiment Construction

[0040] The implementation mode of the present invention is illustrated by specific specific examples below, and those who are familiar with this technology can easily understand other advantages and effects of the present invention from the contents disclosed in this description. Obviously, the described embodiments are a part of the present invention. , but not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0041] The entire operation process in the specific folding process will be further elaborated below in conjunction with the accompanying drawings.

[0042] Specifically, the specific jacket 20 used will be further described. The size of the jacket 20 is 32.34 meters long, 27.84 meters wide, and 48.74 meters high, with a total weight of 1700 tons. Four main support pipes are used to connect four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com