Interlayer concave combined type unit curtain wall

A unit curtain wall and combined technology, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of unguaranteed installation quality on site, many vertical decorative metal plate components, and difficulty in ensuring flatness, etc., so as to improve the overall economic benefits, Facilitate quality control and reduce potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

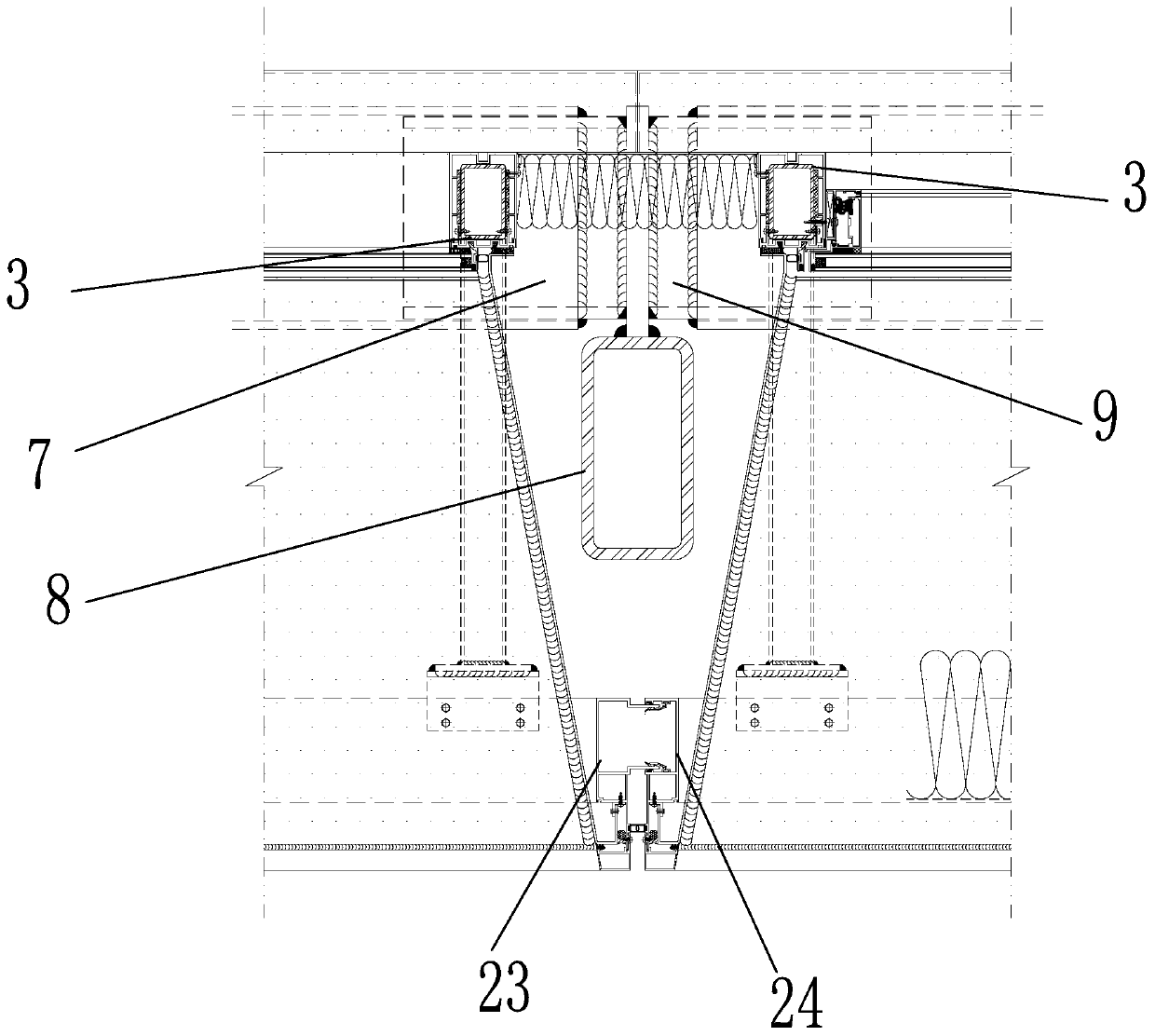

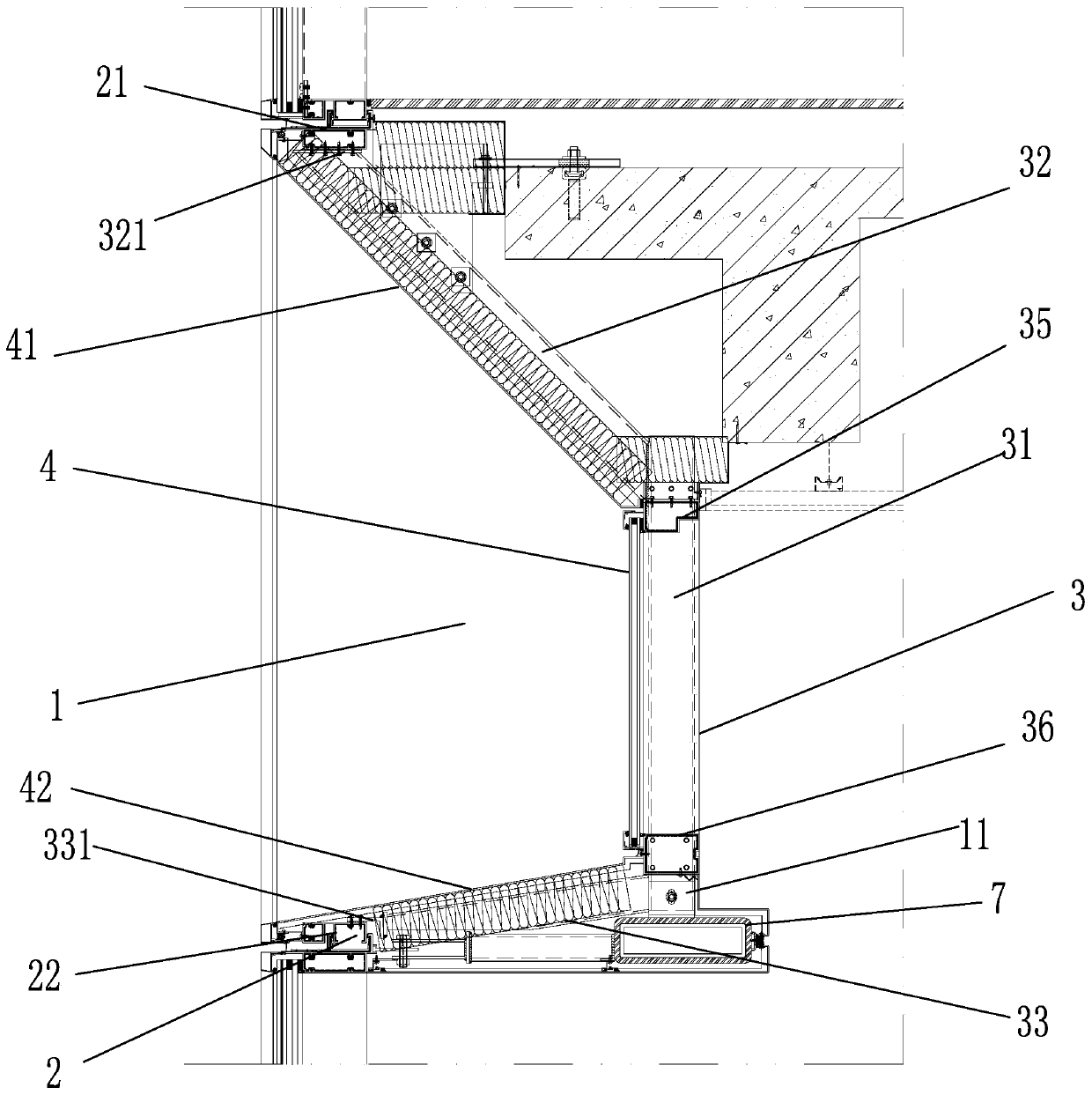

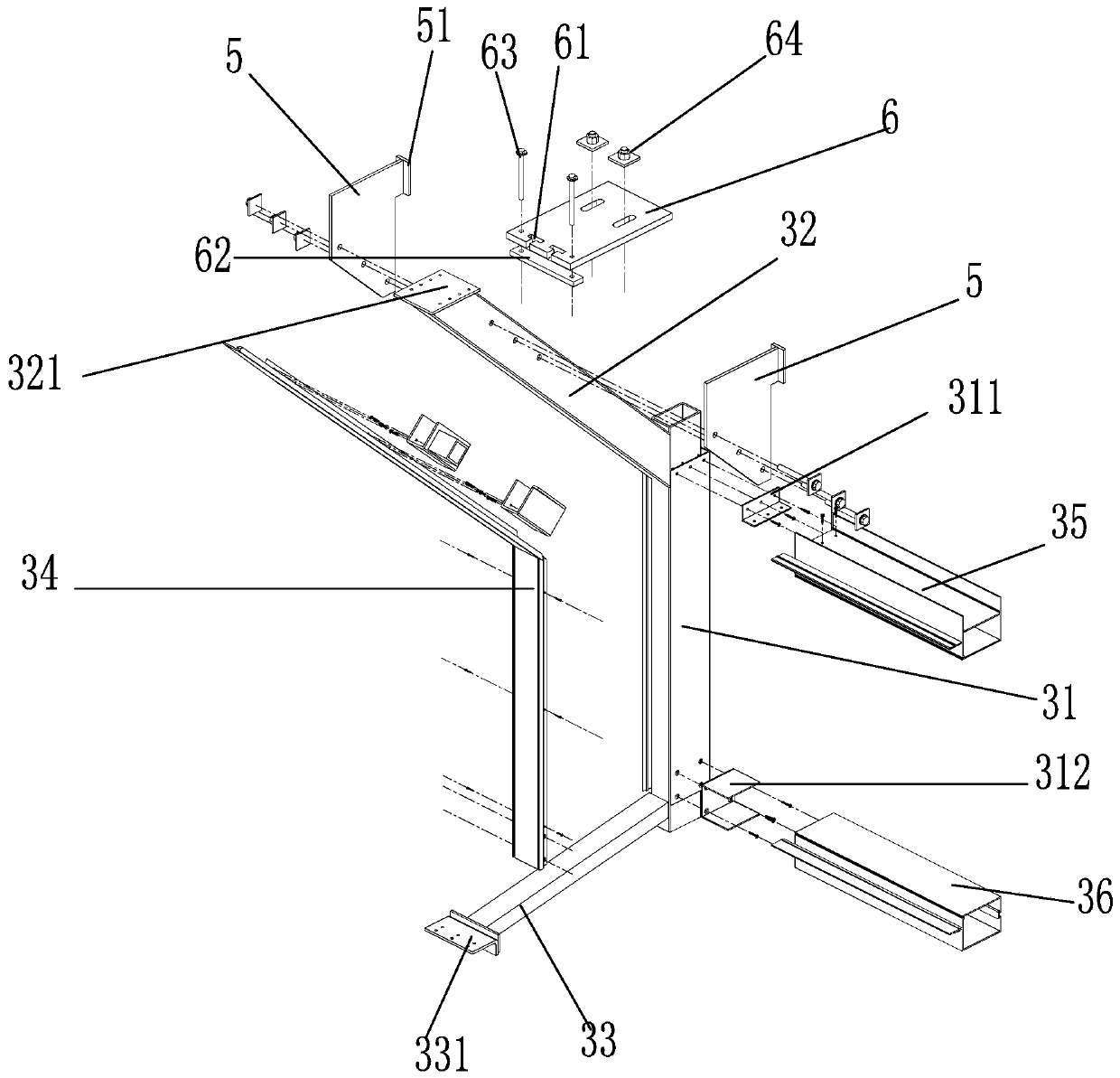

[0026] Such as Figure 1-Figure 7 As shown, the present invention provides an interlayer concave combined unit curtain wall, which includes a plurality of concave units 1, and each concave unit 1 is successively connected in the horizontal direction. The concave unit 1 includes a rectangular frame 2 and several single frames 3 .

[0027] The rectangular frame 2 includes an upper crossbeam 21 and a lower crossbeam 22, both ends of which are fixedly connected by a public upright post 23 and a female upright post 24, respectively. The male uprights 23 and the female uprights 24 of adjacent female units 1 are inserted and fixed to each other.

[0028] The single frame 3 includes a vertical single column 31, the top and bottom of the single column 31 are respectively fixed with an upper connecting beam 32 and a lower connecting beam 33, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com