Tensioner and engine assembly

A tensioner and engine technology, applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problems of increased cost, easy wear of ratchet teeth, high cost of plunger, and achieve cost saving, easy adjustment, and easy return effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

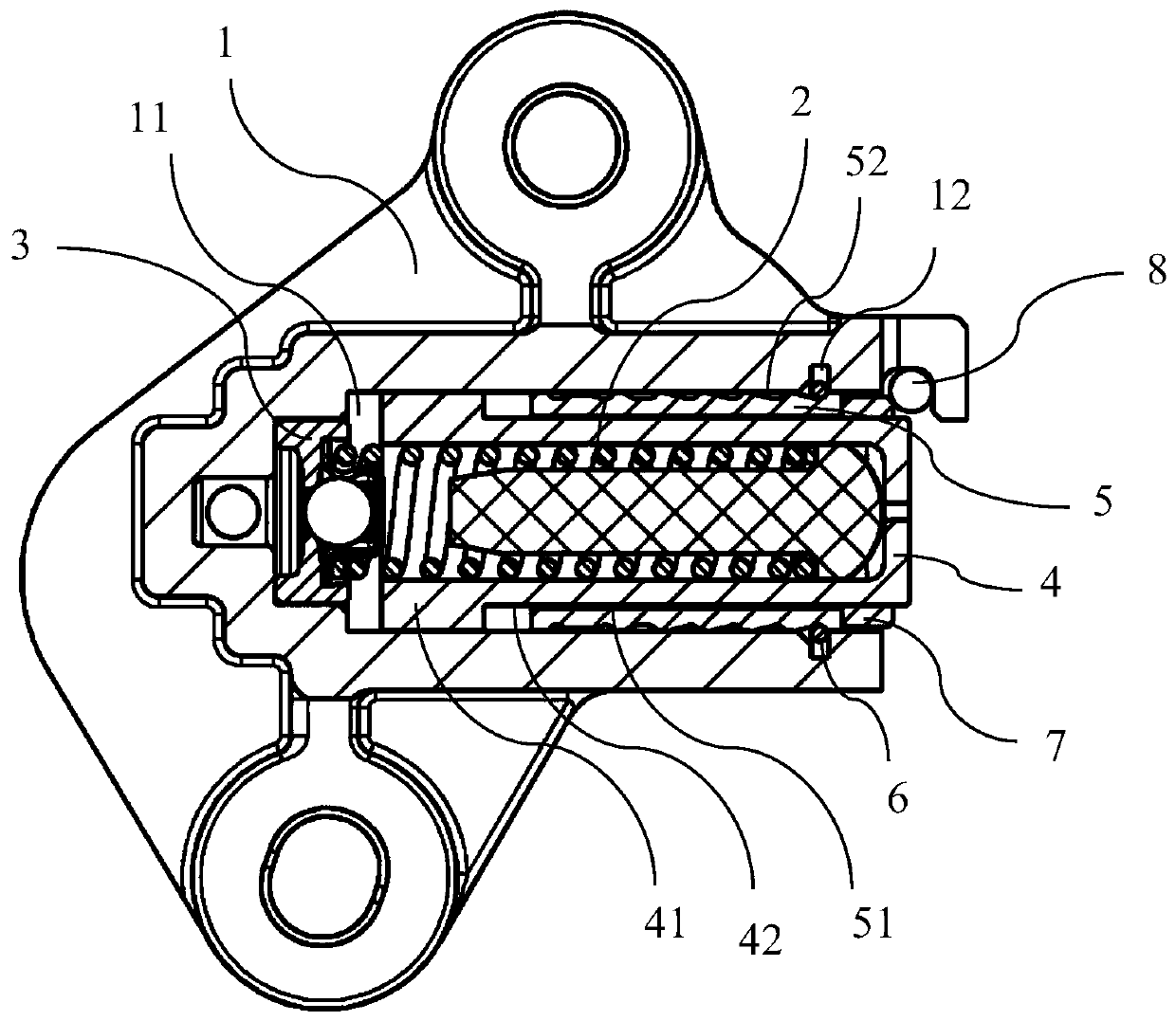

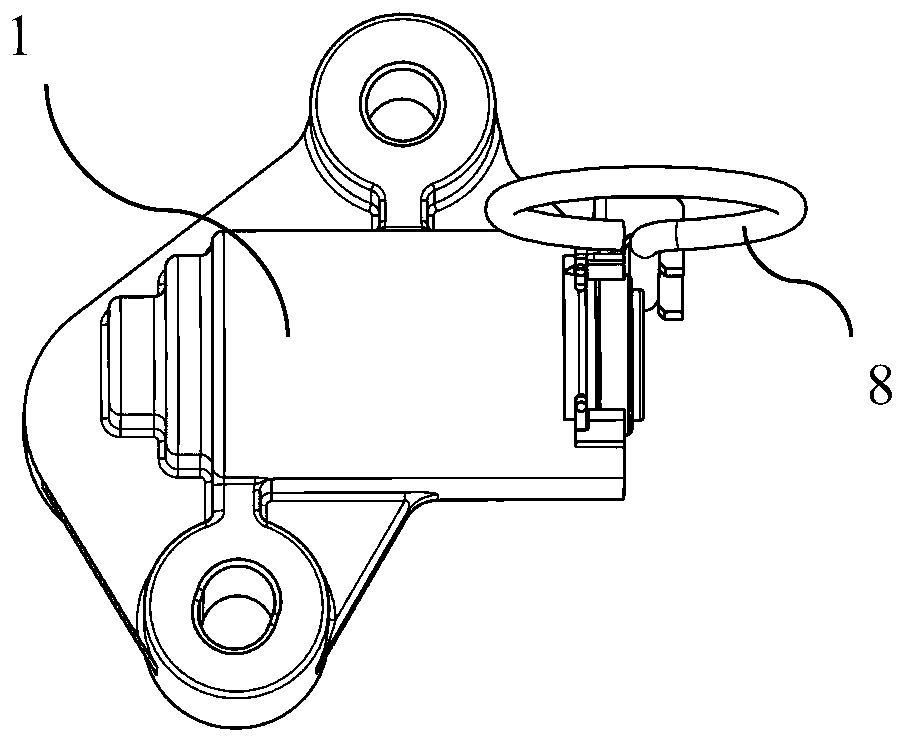

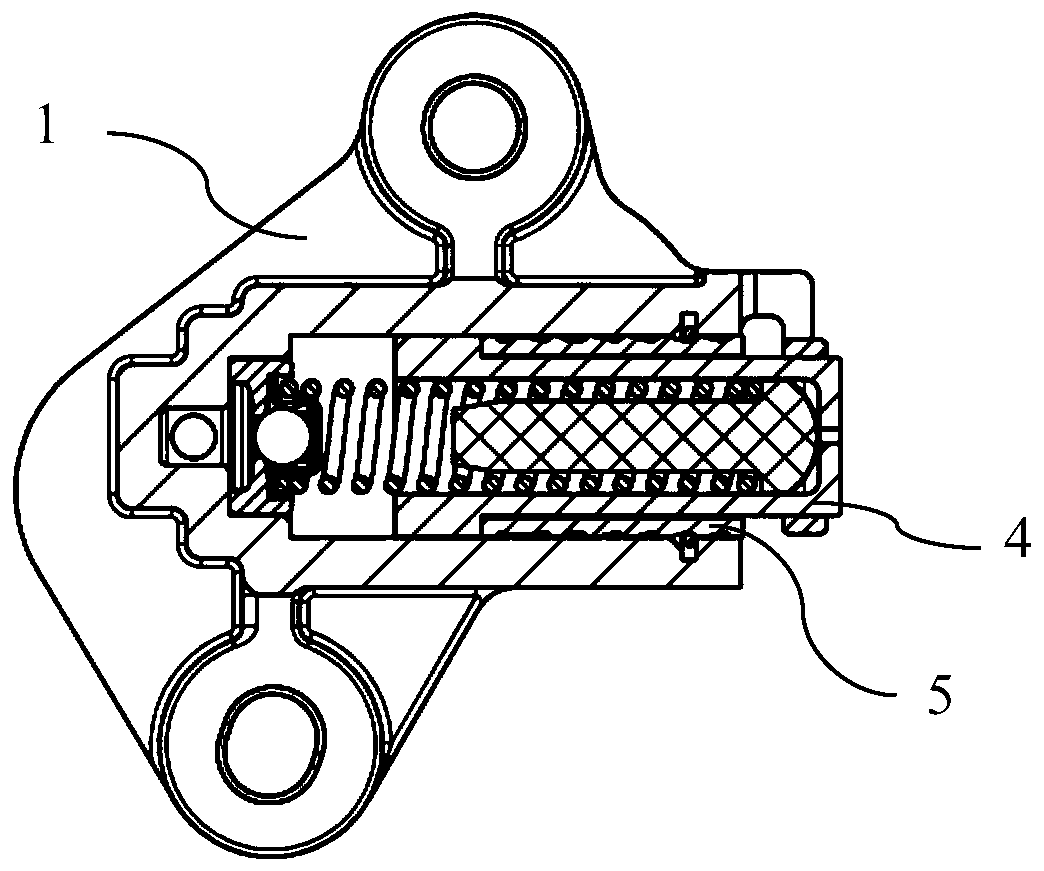

[0030] figure 1 A longitudinal sectional view of a tensioner according to a preferred embodiment of the present invention is shown. The tensioner is configured as a hydraulic tensioner for applying tension to a chain in an engine timing system.

[0031] Such as figure 1As shown, the tensioner includes a housing 1 and a plunger 4 . The housing 1 forms a chamber 11 . The chamber 11 and the plunger 4 adopt a cylindrical structure design in this embodiment. The chamber 11 has an opening on the longitudinal side, ie the axial side. This opening faces a tension arm (not shown) in the engine timing system after the tensioner is assembled to the engine housing. The plunger 4 is at least partially accommodated in the chamber 11 . The plunger 4 is formed with a radially extending collar 41 on the longitudinal end side facing away from the opening of the chamber 11 . Under the combined effect of the spring 2 and the oil delivered to the chamber 11 via the check valve 3, the plunge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com