Multi-channel temperature inspection channel bin and temperature calibrator

A tester and calibrator technology, applied in the electrical field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

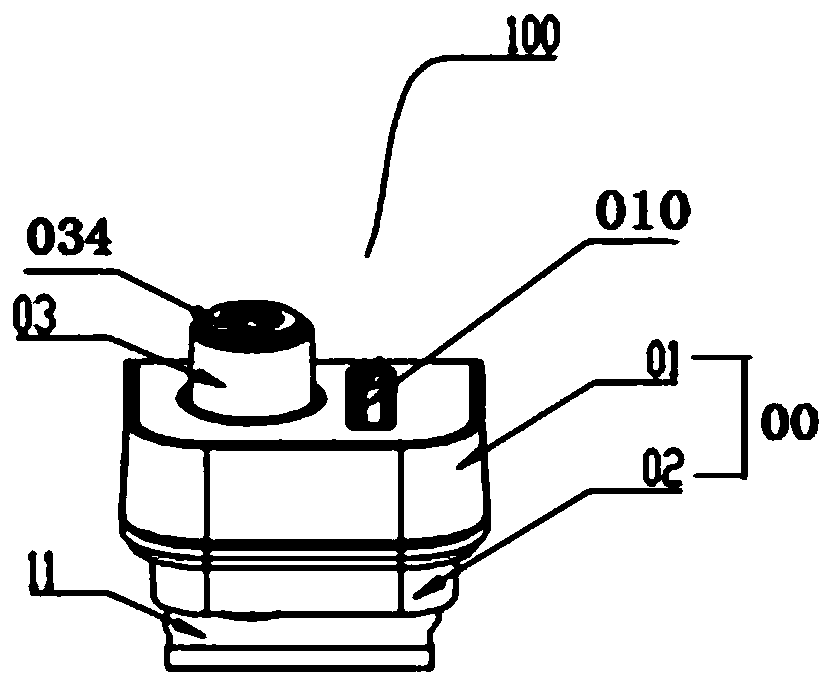

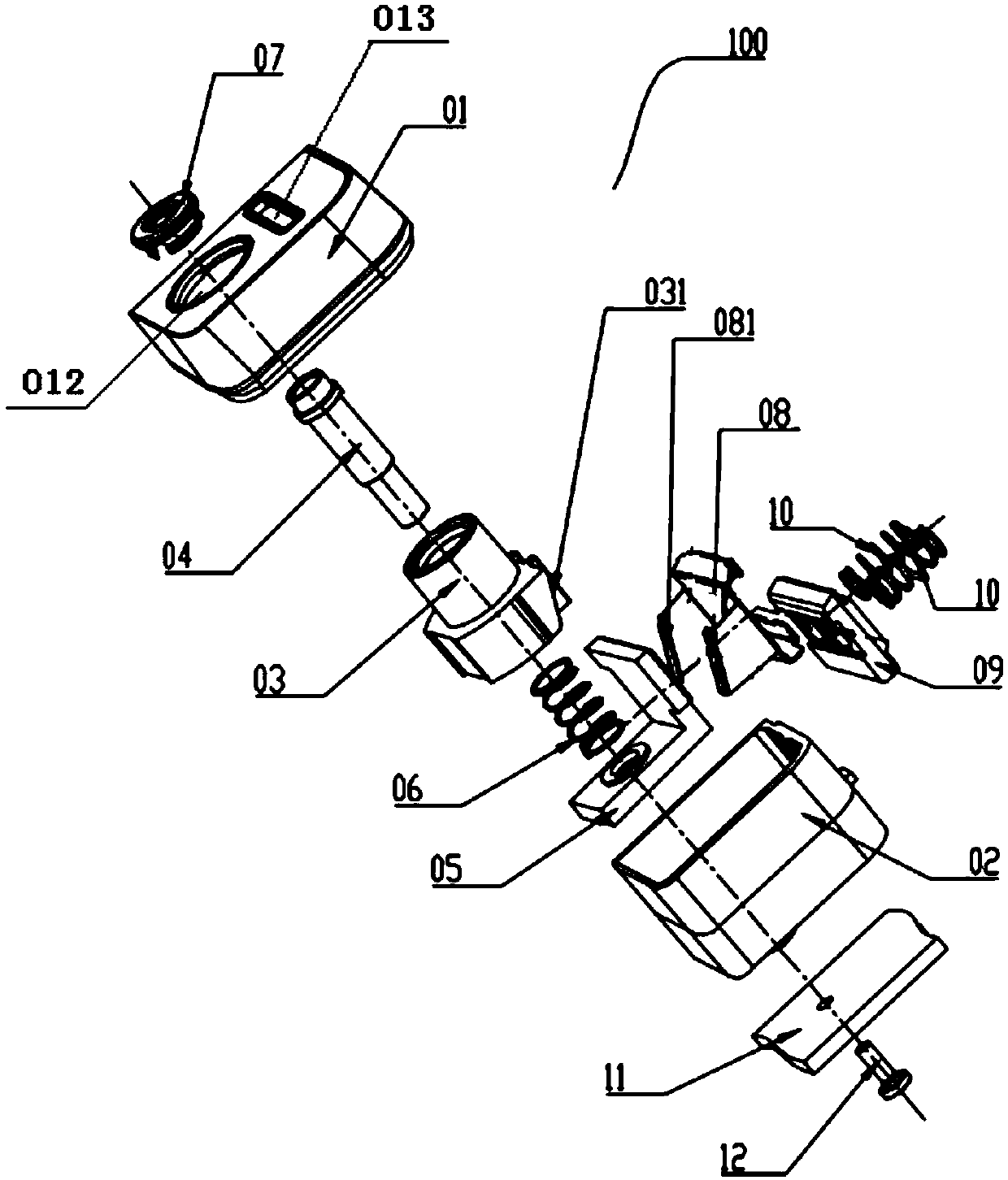

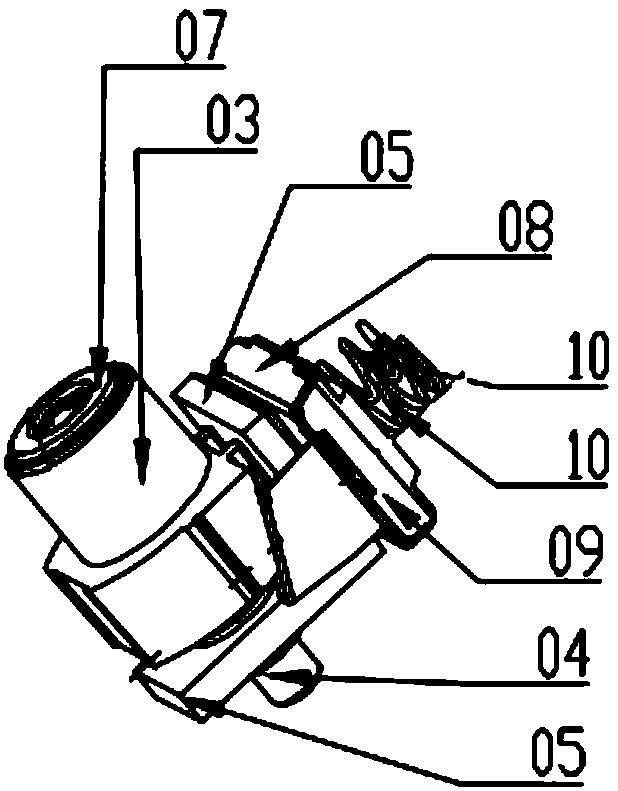

[0107] The crimping terminal of the invention is used for connecting the temperature sensing elements of various sizes and specifications of the test terminal wires. refer to Figure 1 to Figure 3 , the crimp terminal 100 includes a housing 00, a push button 03 and a crimping mechanism. In this embodiment, the crimping mechanism includes a first bonding piece 05 and a second bonding piece 08, and the first bonding piece 05 and the second An openable and closable wiring port 010 is formed at the bonding place of the bonding sheet, wherein the housing 00 is formed by snapping together the surface cover 01 and the lower shell 02, and the surface cover 01 is provided with a first opening 012 and a second opening 013, The push button 03 is located in the casing and its upper part protrudes from the first opening 012 , and the connection opening 010 formed by the first bonding piece 05 and the second bonding piece 08 is located in the casing 00 and faces the second opening of the ca...

Embodiment 2

[0117] Such as Figure 6 As shown, the crimping terminal 101 of the second embodiment is modified on the basis of the crimping terminal 100 of the first embodiment, and the part with the same structure as the crimping terminal 100 of the first embodiment will not be repeated here. The crimping terminal 101 of this embodiment is different from the crimping terminal 100 of the first embodiment in that the two push button slopes 031 of the push button 03 are replaced by two push button arc surfaces 032, and the push button arc surfaces 032 are vertical If it is arranged in the direction, its contact area with the second slope 081 is relatively small (line contact). At this time, in order to prevent the deformation of the second bonding sheet 08, the second bonding sheet 08 can be thickened. Of course, the push button slope 031 of the push button 03 can also be replaced by an end surface of other shapes, as long as the end surface of the push button 03 can be in contact with the f...

Embodiment 3

[0119] Such as Figure 7 As shown, the crimping terminal 102 of the third embodiment is an improvement on the basis of the crimping terminal 100 of the first or second embodiment, and the same structure as the crimping terminal 100 of the first or second embodiment is not mentioned here. Let me repeat. The crimping terminal 102 of this embodiment differs in structure from the crimping terminal 100 of the first embodiment or the crimping terminal 101 of the second embodiment in that the elastic mechanism is a C-shaped elastic piece 18, and the C-shaped elastic piece 18 is located on the second bonding piece. 08 and the inner wall of the housing 00 ( Figure 7 At least one end of the C-shaped opening of the C-shaped elastic piece 18 is supported on the second fitting piece 08 and the C-shaped closed end surface is in contact with the inner wall of the housing 00.

[0120] When the above-mentioned crimping terminal 102 is working, if the terminal of the sensing element with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com