Passivation method for back surface of antimony selenide thin film solar cell

A solar cell and processing method technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of small photoelectric current, low photoelectric conversion efficiency, low filling factor, etc., and achieves reduction of contact potential, passivation The treatment method is simple and easy Line and photoelectric conversion efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The antimony selenide thin film battery is placed on a hot stage with a temperature of 60°C;

[0032] (2) Then 0.5M ErCl 3 The aqueous solution is dripped onto the back surface of the antimony selenide battery, and made to cover the back surface, and allowed to stand for 30 minutes;

[0033] (3) The battery device is placed on a film coating machine, cleaned with deionized water, and dried;

[0034] (4) Electrodes were evaporated on the back side to obtain antimony selenide thin film solar cells, and the current-voltage test was carried out under standard sunlight.

Embodiment 2

[0036] (1) The antimony selenide thin film battery is placed on a hot stage with a temperature of 120°C;

[0037] (2) Then 0.2M ErCl 3 The aqueous solution was dripped onto the back surface of the antimony selenide battery, and made to cover the back surface, and stood for 20 minutes;

[0038] (3) The battery device is placed on a film coating machine, cleaned with deionized water, and dried;

[0039] (4) Electrodes were evaporated on the back side to obtain antimony selenide thin film solar cells, and the current-voltage test was carried out under standard sunlight.

Embodiment 3

[0041] (1) The antimony selenide thin film battery is placed on a hot stage with a temperature of 160°C;

[0042] (2) Then 0.05M ErCl 3 Drop the aqueous solution onto the back surface of the antimony selenide battery, and make it cover the back surface, and let it stand for 10 minutes;

[0043] (3) The battery device is placed on a film coating machine, cleaned with deionized water, and dried;

[0044] (4) Then the electrode was vapor-deposited on the back side to obtain the antimony selenide thin film solar cell, and the surface potential and the current-voltage test under standard sunlight were carried out on it.

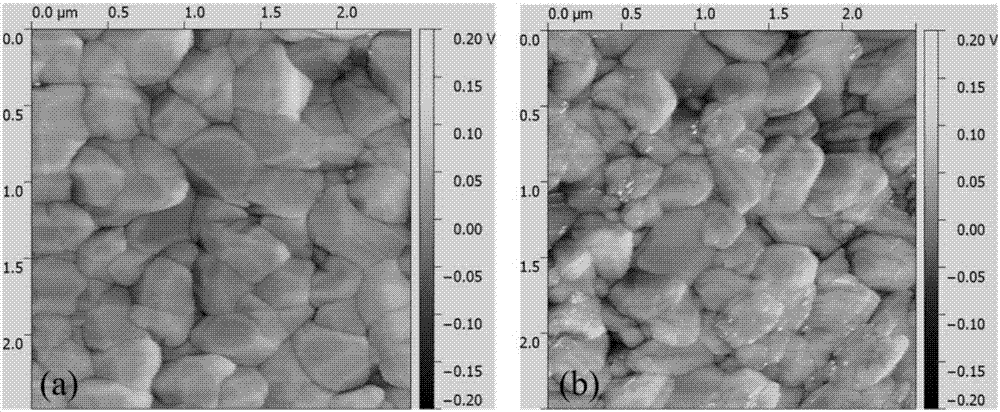

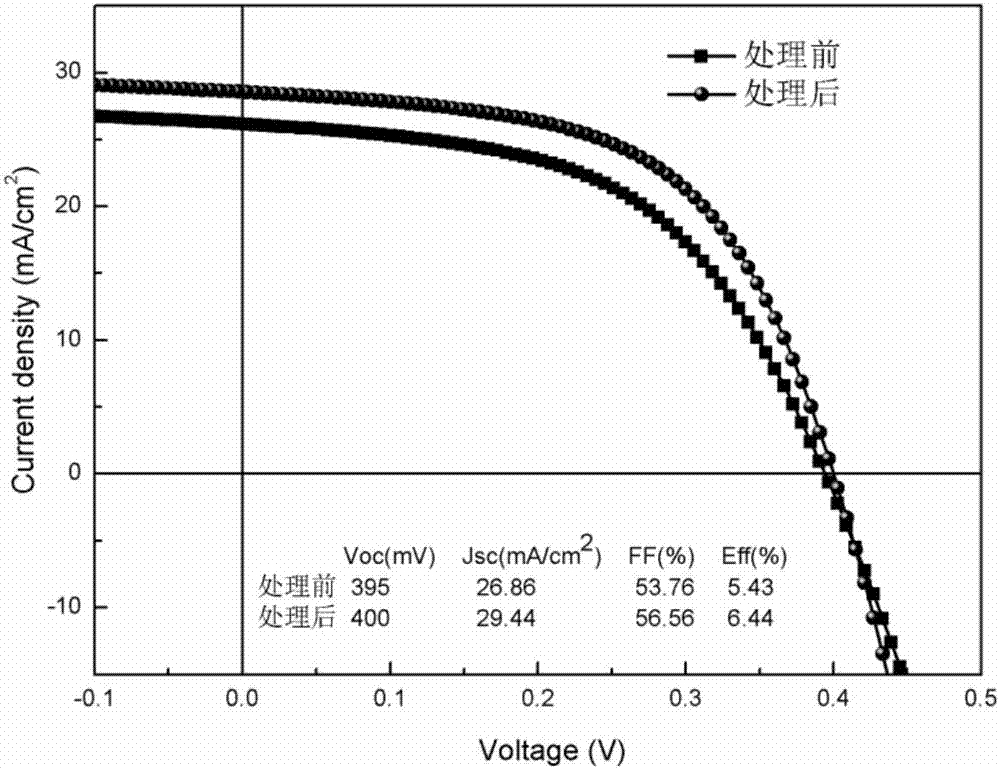

[0045] The Kelvin probe potential mapping diagram is as follows figure 1 as shown, figure 1 (a) is the test result before treatment, figure 1 (b) is ErCl 3 The test results after the solution treatment, the results show that the potential of the antimony selenide surface becomes higher after treatment, thereby reducing the contact barrier between the antimony...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com