A three-area split visible fireproof cable trench

A technology of fireproof cables and cable trenches, which is applied in the installation of cables and cables in underground pipelines, etc. It can solve the problems of inconvenient opening of the cover, low reuse rate, and inability to disassemble multiple times, so as to improve fire isolation effect, increase the frequency of inspection and maintenance, and improve the effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] For the convenience of description, the length direction of the cable trench is taken as the front-to-back direction, the width direction of the cable trench is taken as the left-right direction, the front-to-back direction is taken as the longitudinal direction, and the left-right direction is taken as the transverse direction.

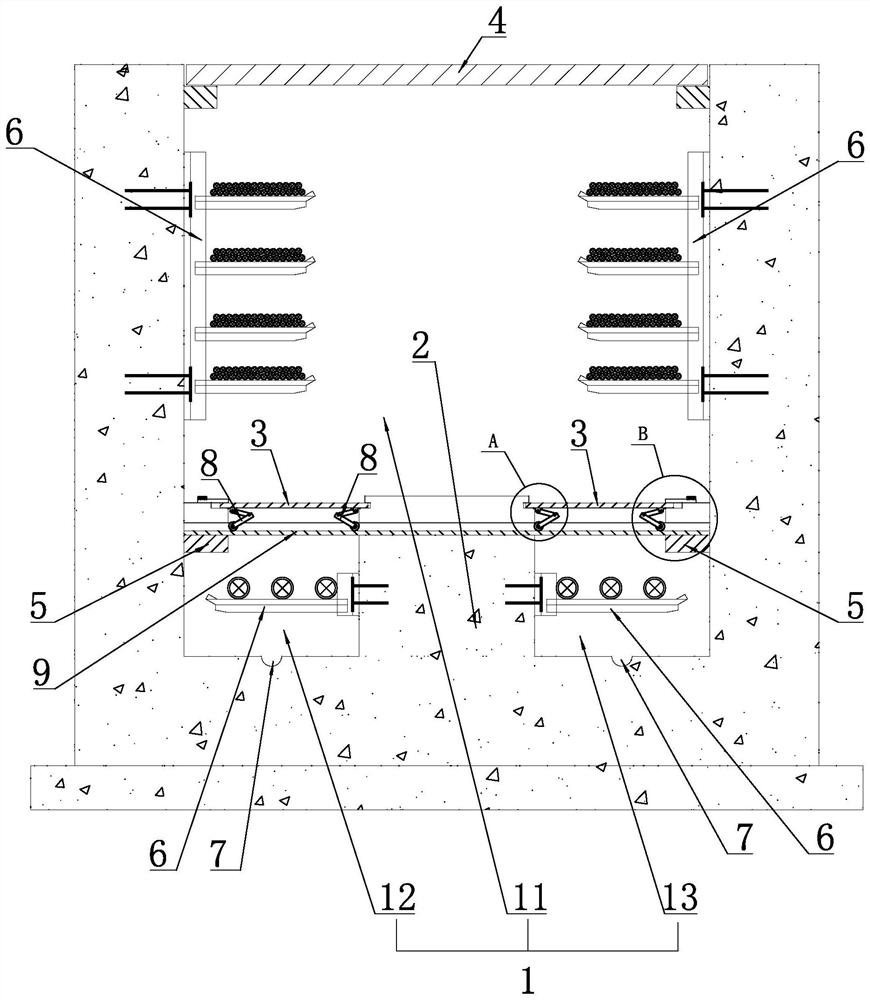

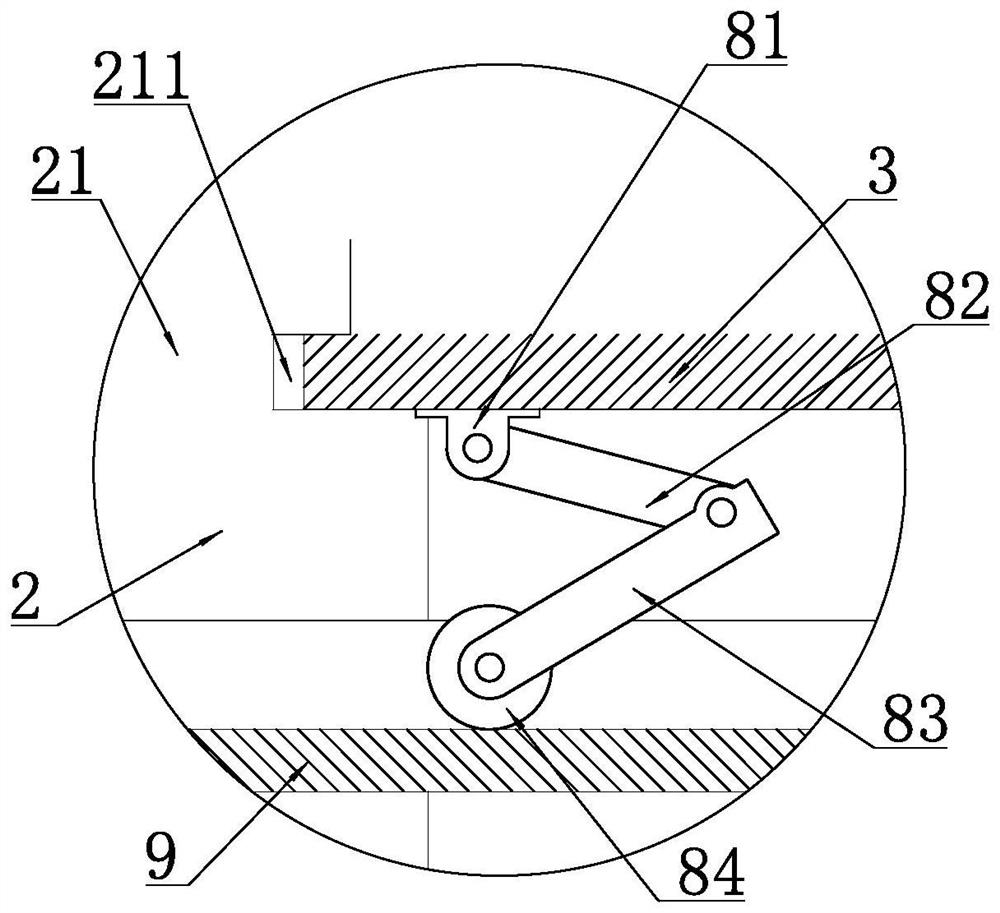

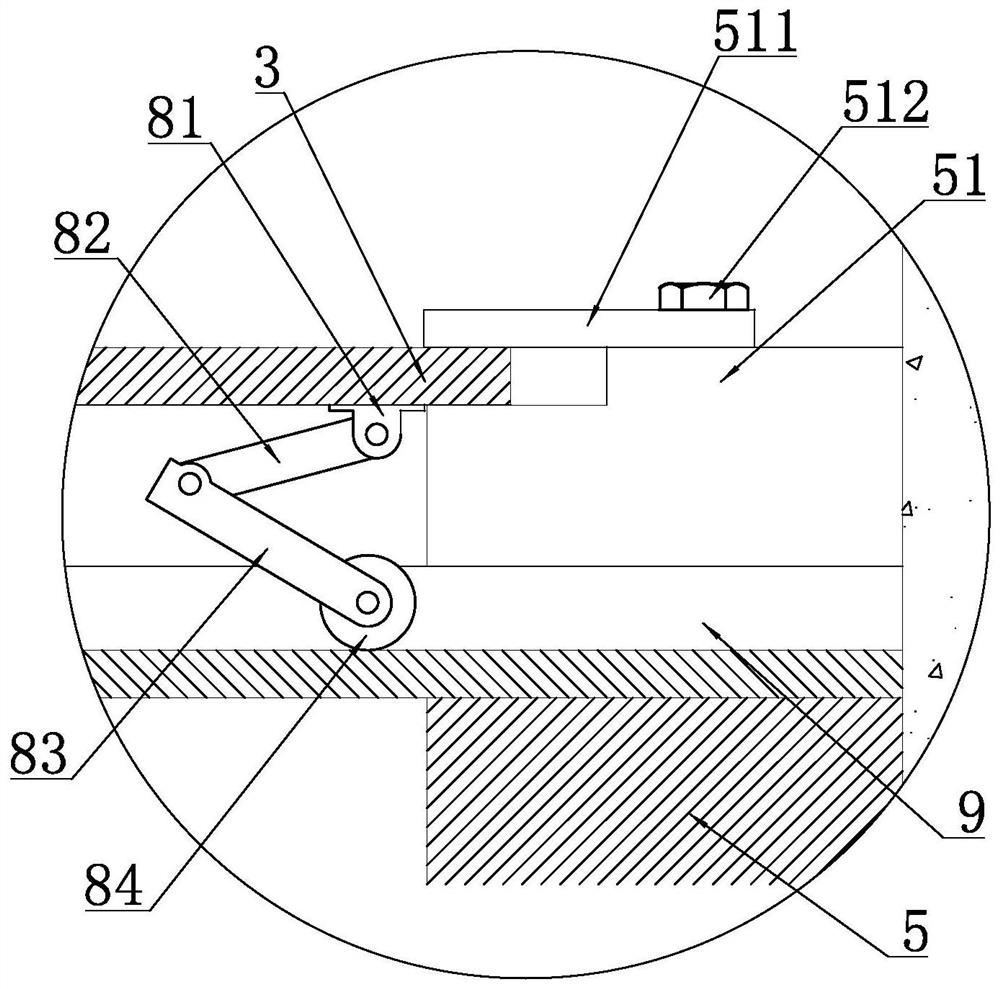

[0037] Such as figure 1 As shown, a three-area split visible fireproof cable trench includes a cable trench 1, and the upper opening of the cable trench 1 is provided with a plurality of upper cover plates 4 for closing the cable trench 1 along the front and rear directions. The middle part of the bottom surface of the cable trench 1 is provided with a fireproof partition wall 2 extending along the front and back direction, and the fireproof partition wall 2 divides the lower space of the cable trench 1 into left and right parts. Between the left and right side walls of the fire partition wall 2 and the cable trench 1, a plurality of visible c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com