Bumper system

A bumper and bumper beam technology, applied in the field of bumper systems, can solve problems such as low strength and low specific gravity, and achieve the effect of preventing lateral fall and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

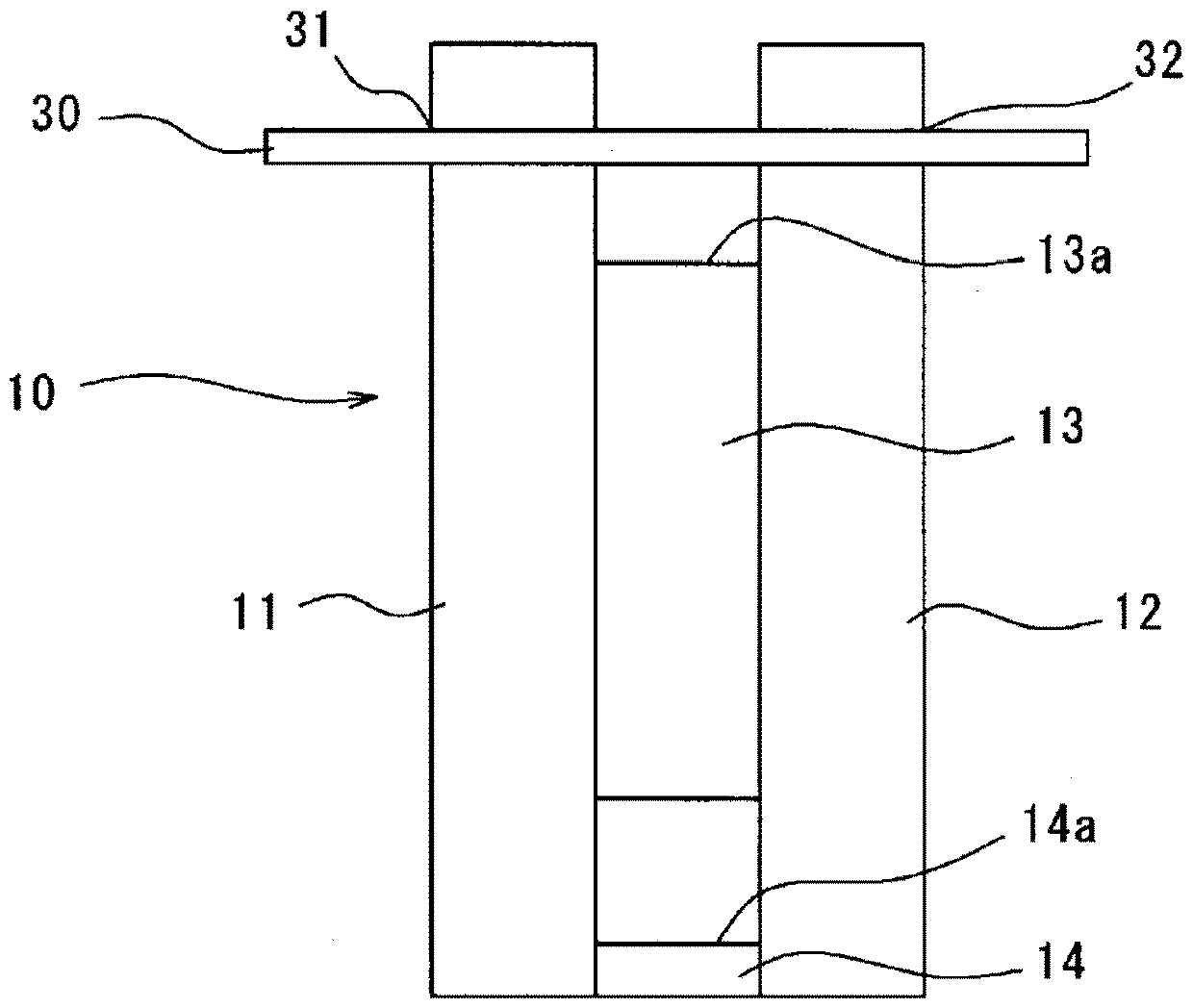

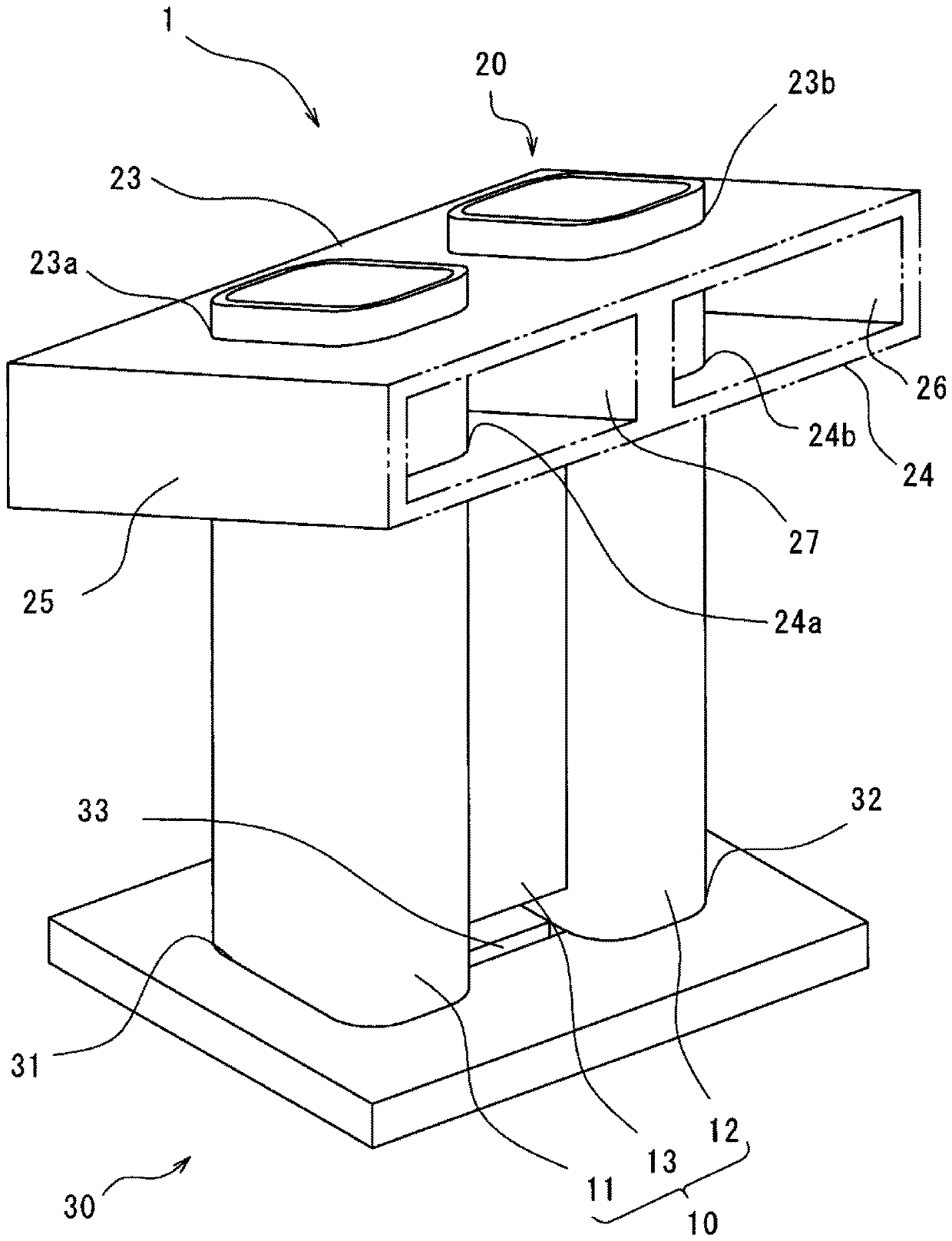

[0048] like figure 1 As shown, the bumper bracket 10 is a member that connects a bumper beam 20 to be described later and a vehicle body panel 30 . In the present embodiment, two bumper brackets 10 having the same shape connect one bumper beam 20 to two vehicle body panels 30 . Hereinafter, the direction in which the bumper beam 20 extends (direction X in the figure) is referred to as the width direction of the vehicle, the direction in which the bumper bracket 10 extends (direction Y in the figure) is referred to as the front-rear direction of the vehicle, and The direction (Z direction in the figure) perpendicular to these directions is referred to as the height direction of the vehicle.

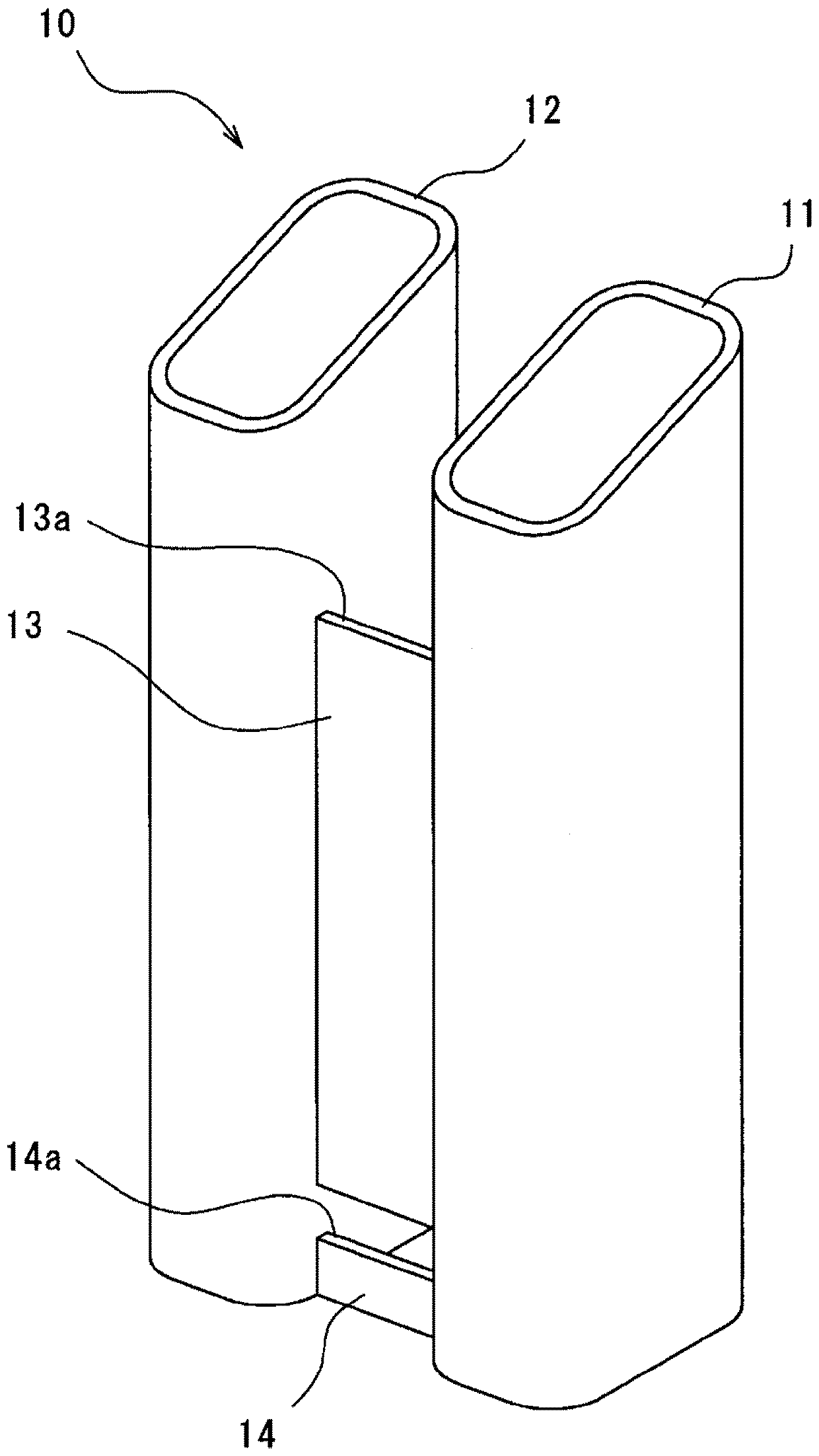

[0049] like figure 2 and image 3 As shown, the bumper bracket 10 passes through the first connecting rib 13 (refer to figure 2 ) and the second connecting rib 14 at the other end (refer to image 3 ) to connect the first pipe body 11 and the second pipe body 12 extending in the fro...

no. 2 Embodiment approach )

[0071] exist Figure 13 to Figure 18 In the bumper system 1 according to the second embodiment shown, the shape of the second connection rib 14 is different. In addition to the structure of this, with Figure 1 to Figure 7 The structure of the bumper system 1 of the first embodiment is the same. Therefore, the same reference numerals may be assigned to the same components as those in the configuration shown in the first embodiment, and description thereof may be omitted.

[0072] In this embodiment, the plate slit 33 and beam slit 23c, 24c are not provided like 1st Embodiment and its modification. Instead, as will be described later, the second connection rib 14 is connected to the first pipe body 11 and the second pipe body 12 by welding.

[0073] Like the first embodiment, the first connecting rib 13 of the bumper bracket 10 is along the front-rear direction of the vehicle ( figure 1 The Y direction) extends the plate-shaped part. The first connecting rib 13 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com