Textile size stirring device for textile

A textile slurry and stirring device technology, applied in the textile field, can solve the problems affecting the quality of textile dyed cloth, reducing the stirring speed, affecting the stability of textile processing process and product quality stability, etc., and achieve good stirring effect and good operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

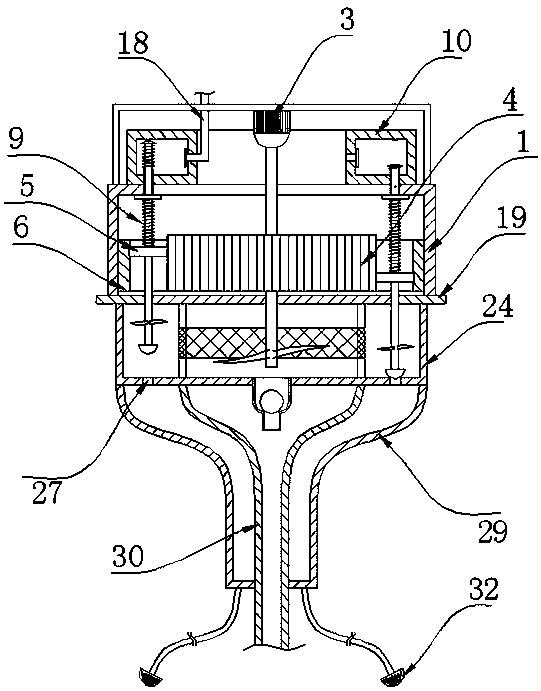

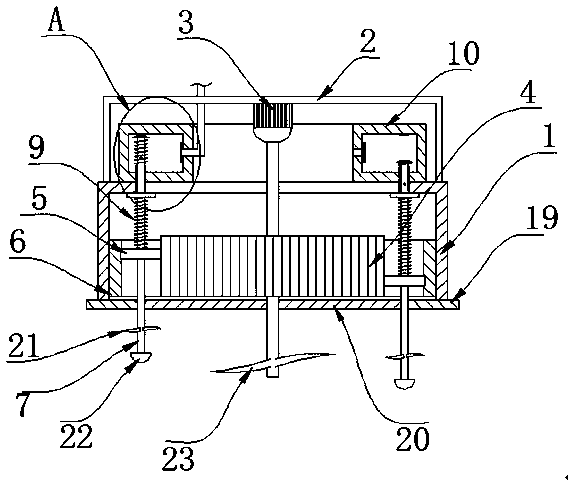

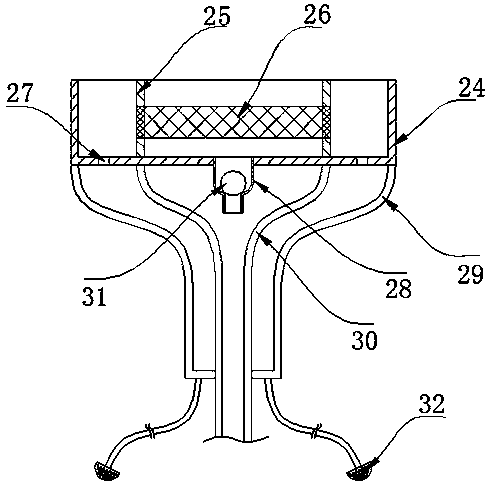

[0027] refer to Figure 1-5 , a textile slurry stirring device for weaving, a cylindrical cover body 1 and a liquid storage box 24, a circular hole is opened on the upper wall of the cover body 1, and a frame is fixed on the outer upper wall of the cover body 1 2. A motor 3 is fixedly connected to the middle part of the lower wall of the frame 2. The output shaft of the motor 3 runs through the round hole on the top of the cover body 1 and is fixedly connected to a wide gear 4. The wide gear 4 meshes with multiple planetary gears 5;

[0028] The inner side wall of the cover body 1 is fixedly connected with a wide ring gear 6, the teeth of the wide ring gear 6, the planetary gear 5 and the wide gear 4 are all straight tooth structures, the positions of the wide ring gear 6 and the wide gear 4 are fixed, and the wide The length of the gear 4 and the wide ring gear 6 in the vertical direction is greater than the length of the planetary gear 5, the axis of the planetary gear 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com