Bolt universal component sorting device

A technology for general parts and bolts, applied in the field of bolt general parts sorting equipment, can solve the problems of affecting the accuracy of screening, time-consuming and laborious, error-prone, etc., and achieve the effect of comprehensive sorting, high sorting efficiency, and reducing detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with embodiment.

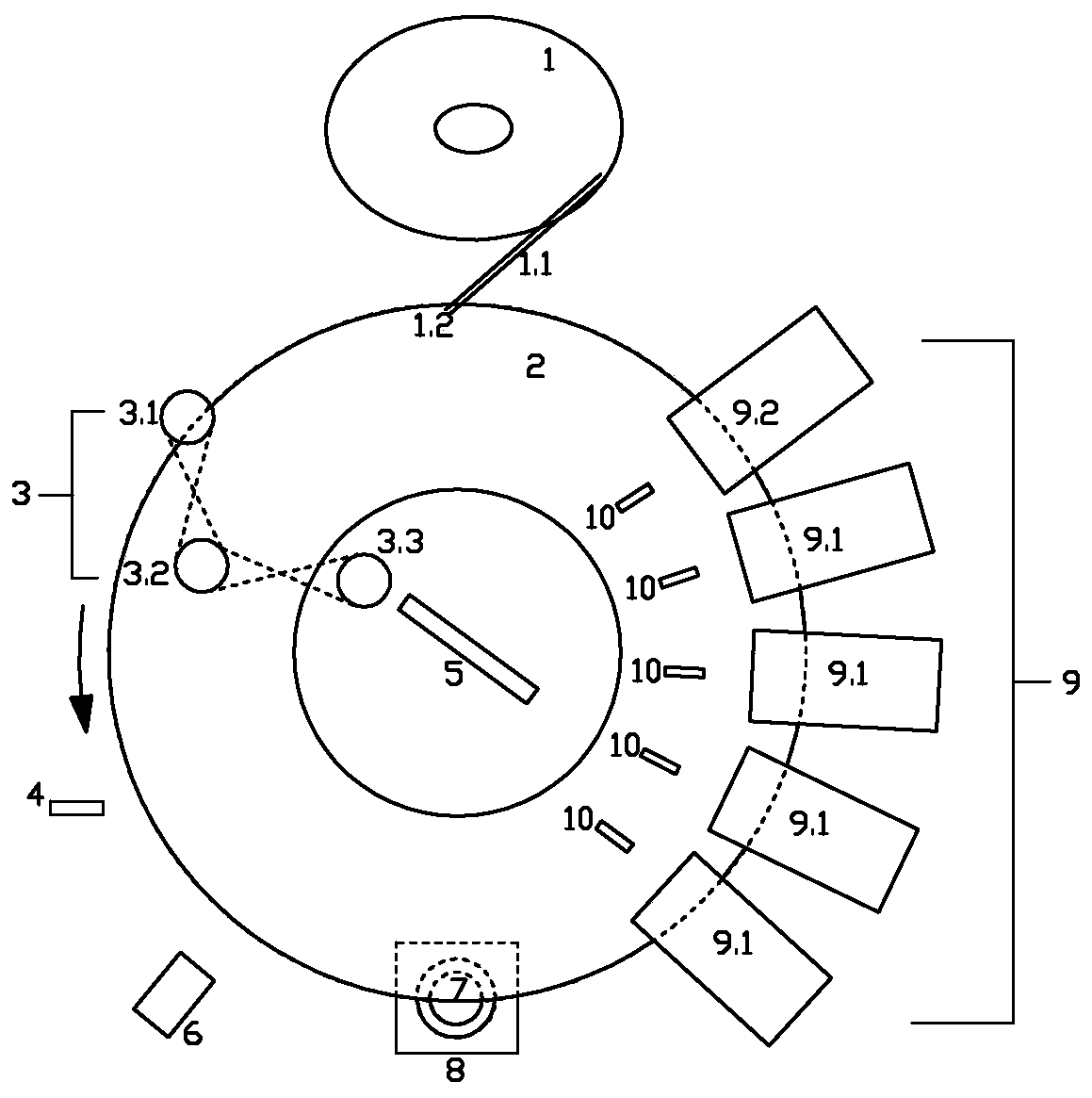

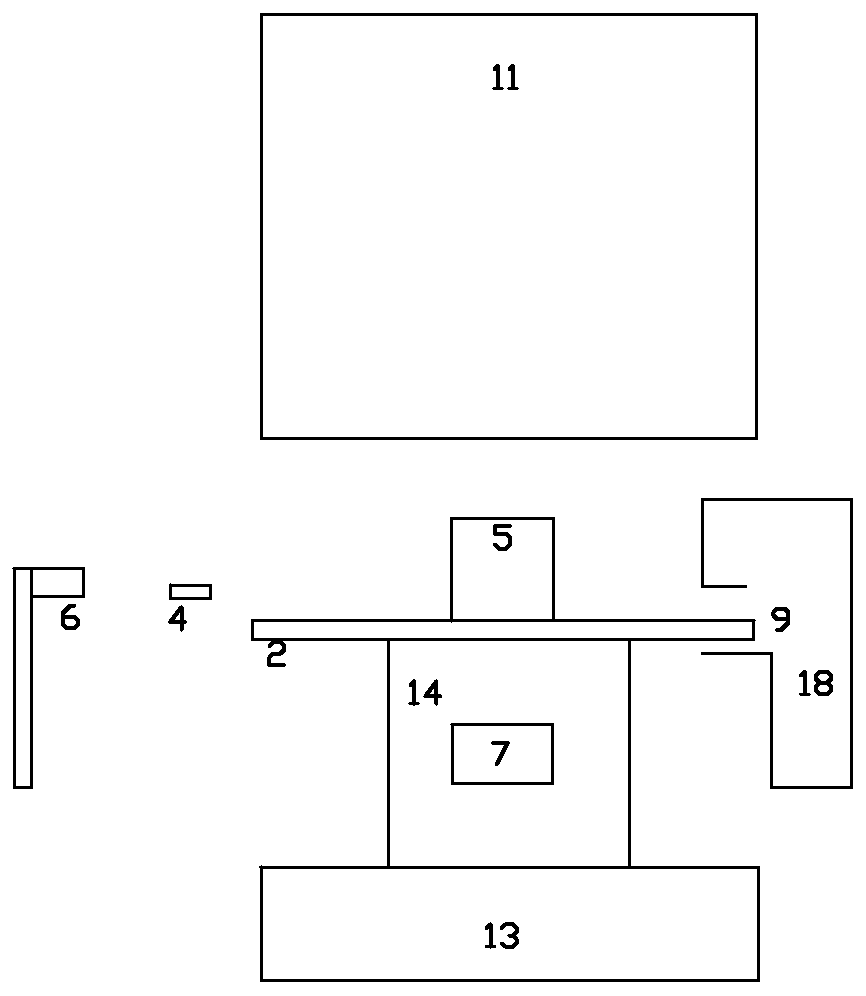

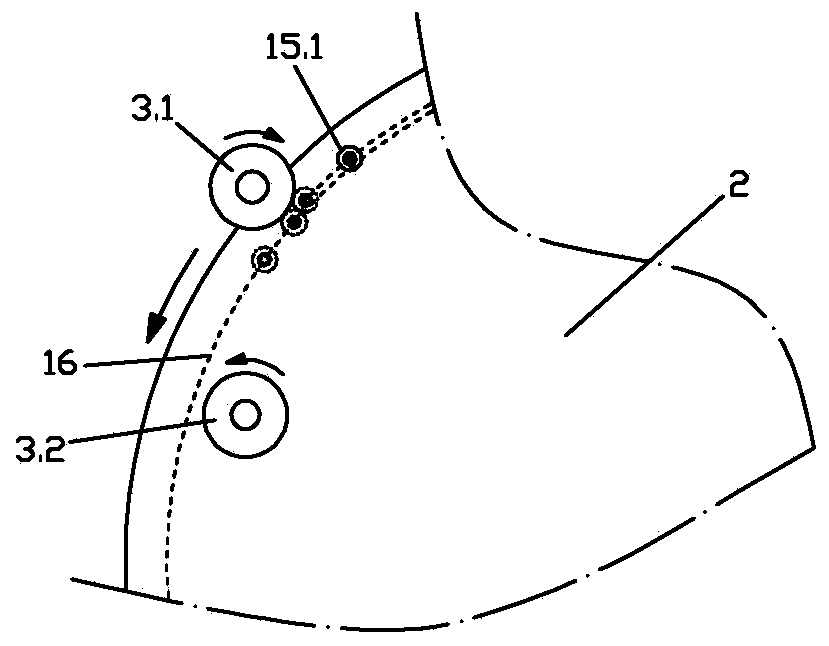

[0043] Such as figure 1 and figure 2 The shown sorting equipment for common parts of bolts includes a bolt feeder 1, a rotary table 14, a transparent glass plate 2, a bolt position adjustment device 3, a side camera 6, a side light source 5, a bottom camera 7, a bottom light source 8, Computer, five bolts select delivery mechanism 10 and five discharge ports 9.

[0044] The bolt feeder 1 is a conventional vibrating disc feeder, which is provided with an outwardly extending output track 1.1. The outer end of the output track 1.1 is the discharge end 1.2. Arranging and entering the output track one by one, and the bolts output one by one from the discharge end 1.1 are in a vertical state, with the head of the bolt facing down.

[0045]The above-mentioned conventional vibrating disc feeder is powered by its vibrating disc, and the side of the vibrating disc feeder is provided with a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com