Jacking and rotating mechanism and welding device

A rotating mechanism and lifting technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unfavorable cost control, high limitations, and achieve compact, streamlined structure and good buffering effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

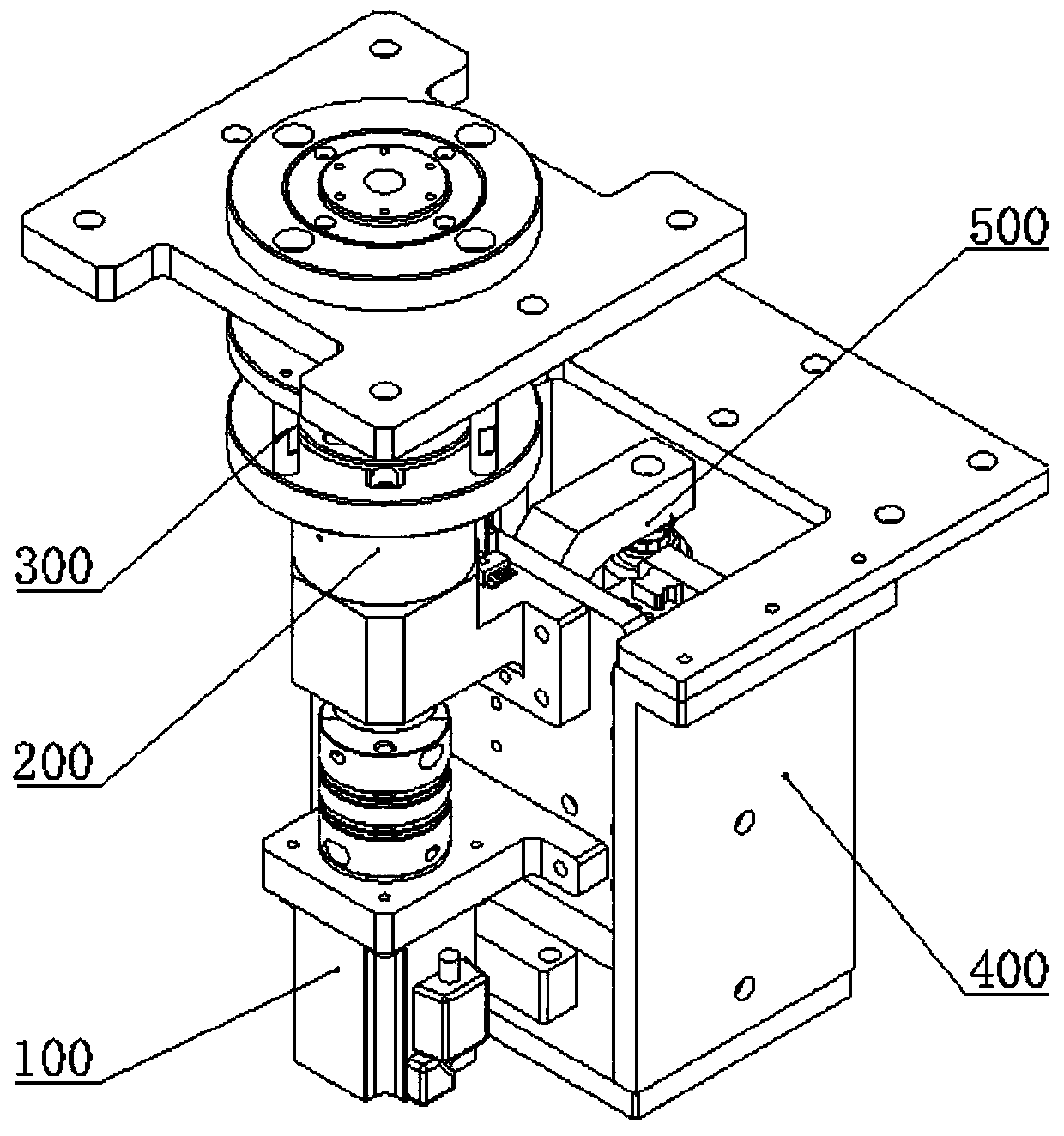

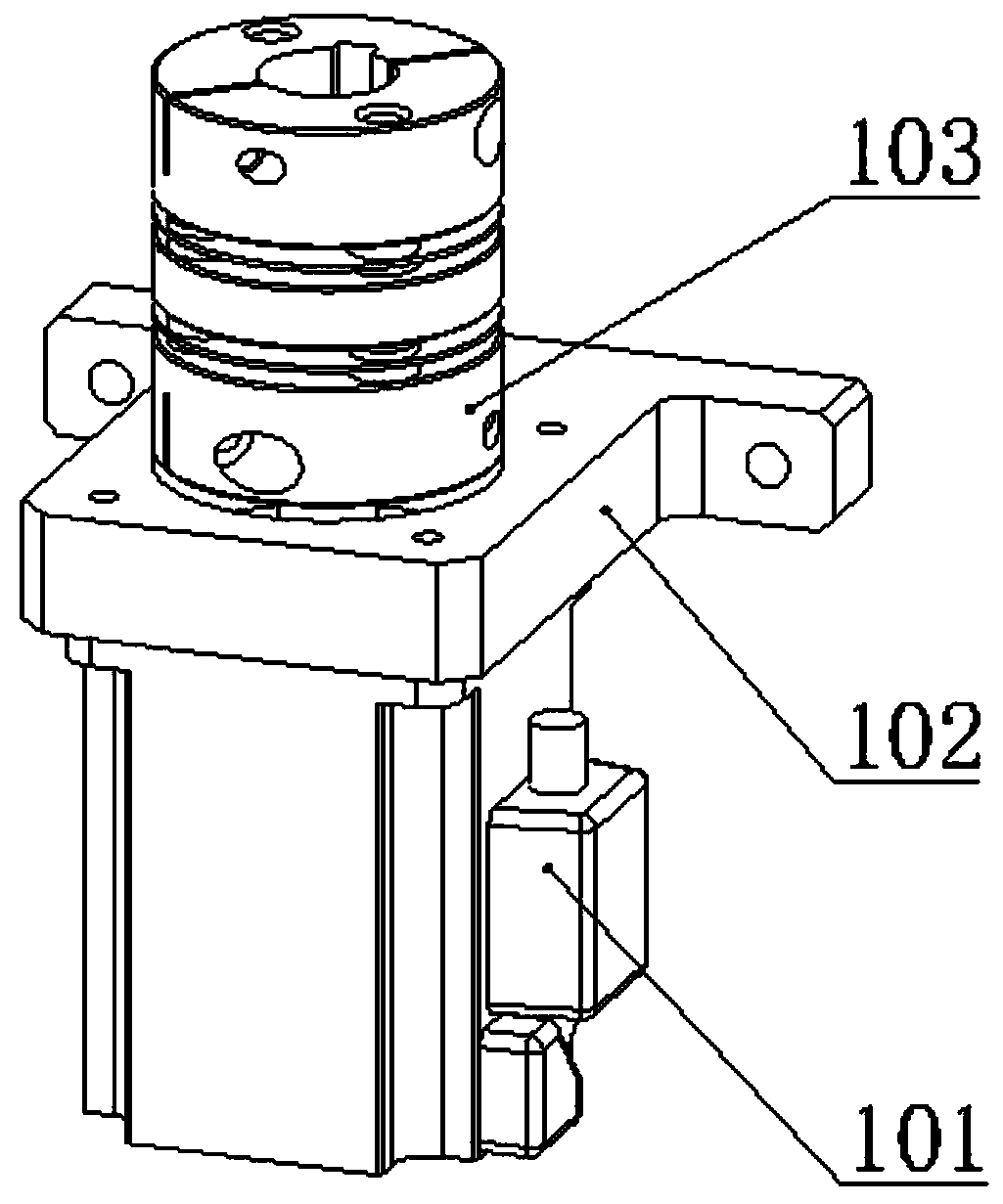

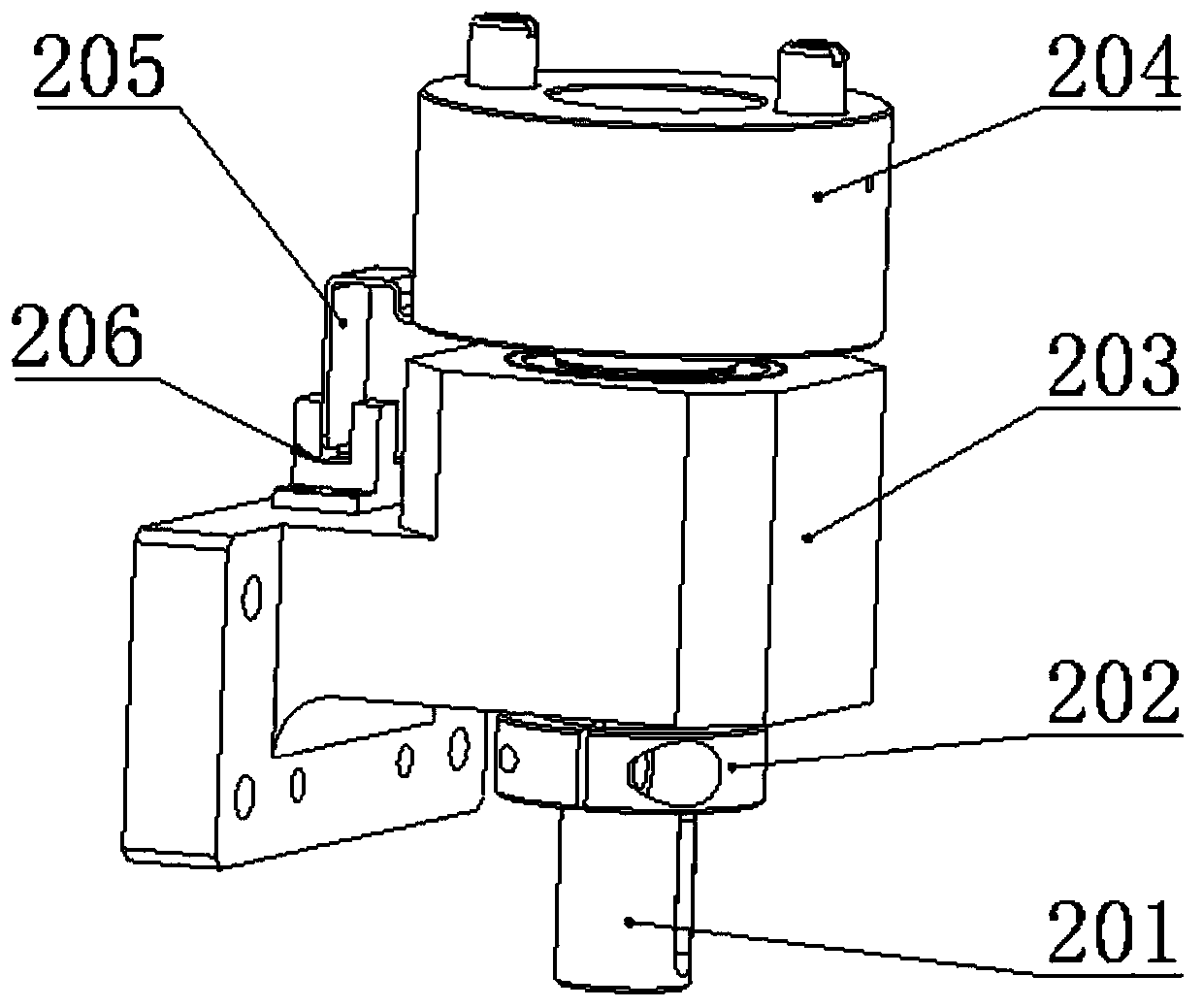

[0038] A jacking rotation mechanism, such as Figure 1 to Figure 8 As shown, it includes a base 400 , a driving assembly 100 , a rotating assembly 300 and a jacking assembly 500 .

[0039]The jacking assembly 500 is arranged on the base 400, the driving assembly 100 is arranged on the jacking assembly 500, the rotating assembly 300 is installed on the jig table to be rotated and is connected with the driving assembly 100 connection, the driving assembly 100 drives the rotating assembly 300 to rotate, the jacking assembly 500 drives the driving assembly 100 and the rotating assembly 300 to lift, the base 400 is installed on the workbench of the welding equipment, and the rotating assembly 300 is installed On the fixture platform that needs to be rotated, the jacking assembly 500 lifts the driving assembly 100 to a predetermined position, and the driving assembly 100 drives the rotating assembly 300 to rotate, and the relevant parts in the rotating assembly 300 can rotate along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com