Automatic welding machine

An automatic welding machine and laser welding technology, applied in welding equipment, laser welding equipment, other manufacturing equipment/tools, etc., can solve problems such as low stability and reliability, poor product processing quality, and reduced product competitiveness, and achieve The effect of high stability and reliability, high processing accuracy, and easy production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

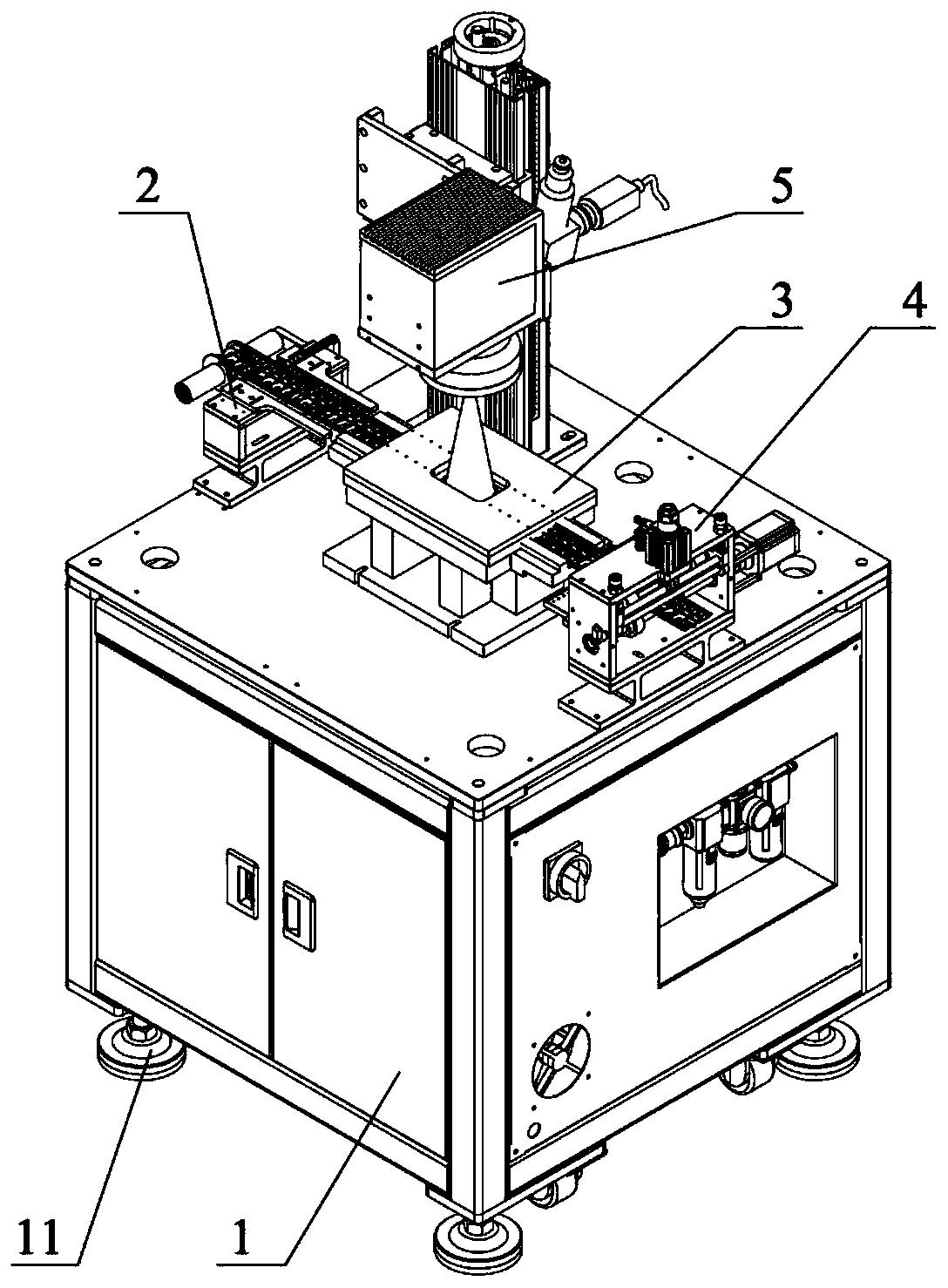

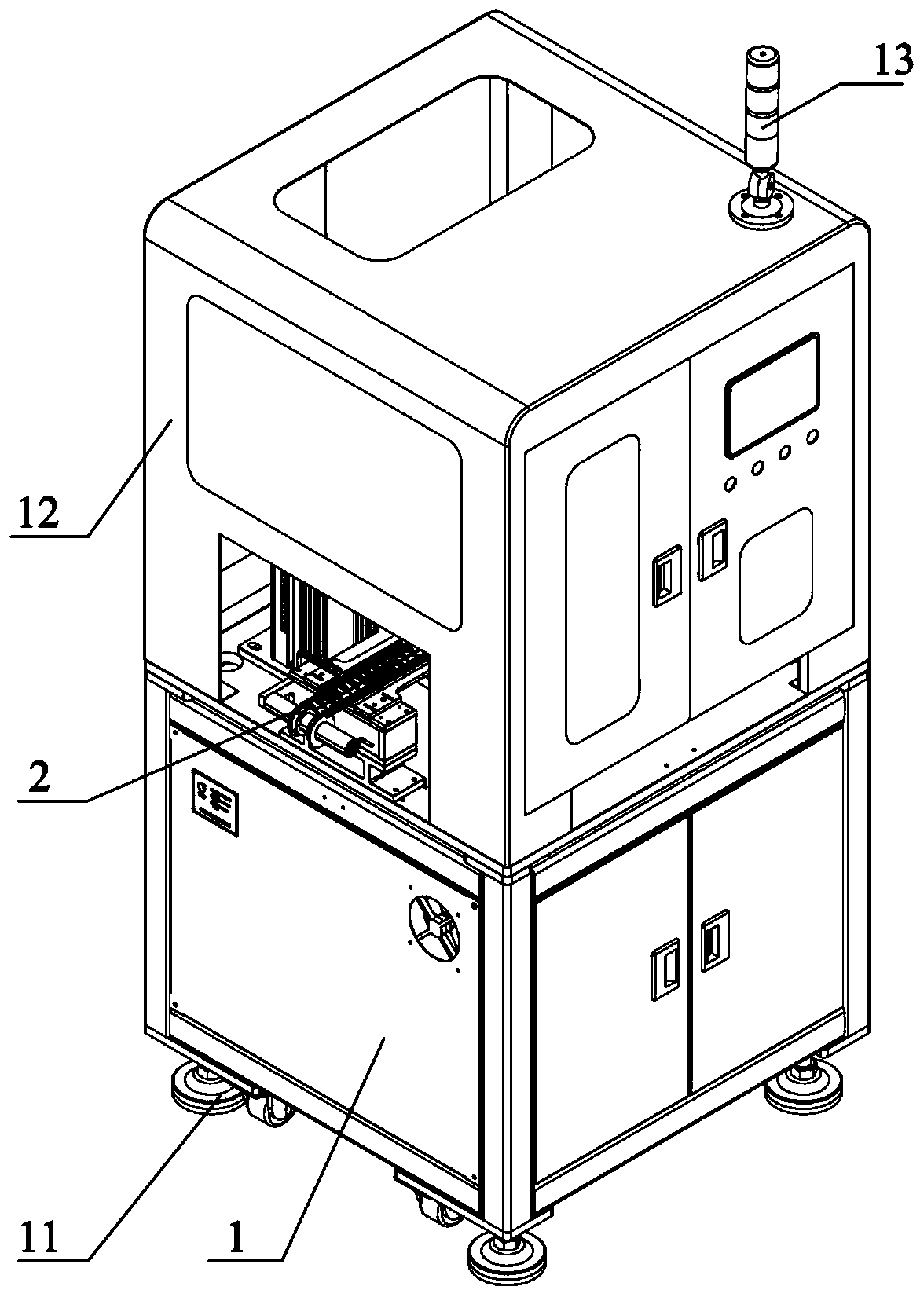

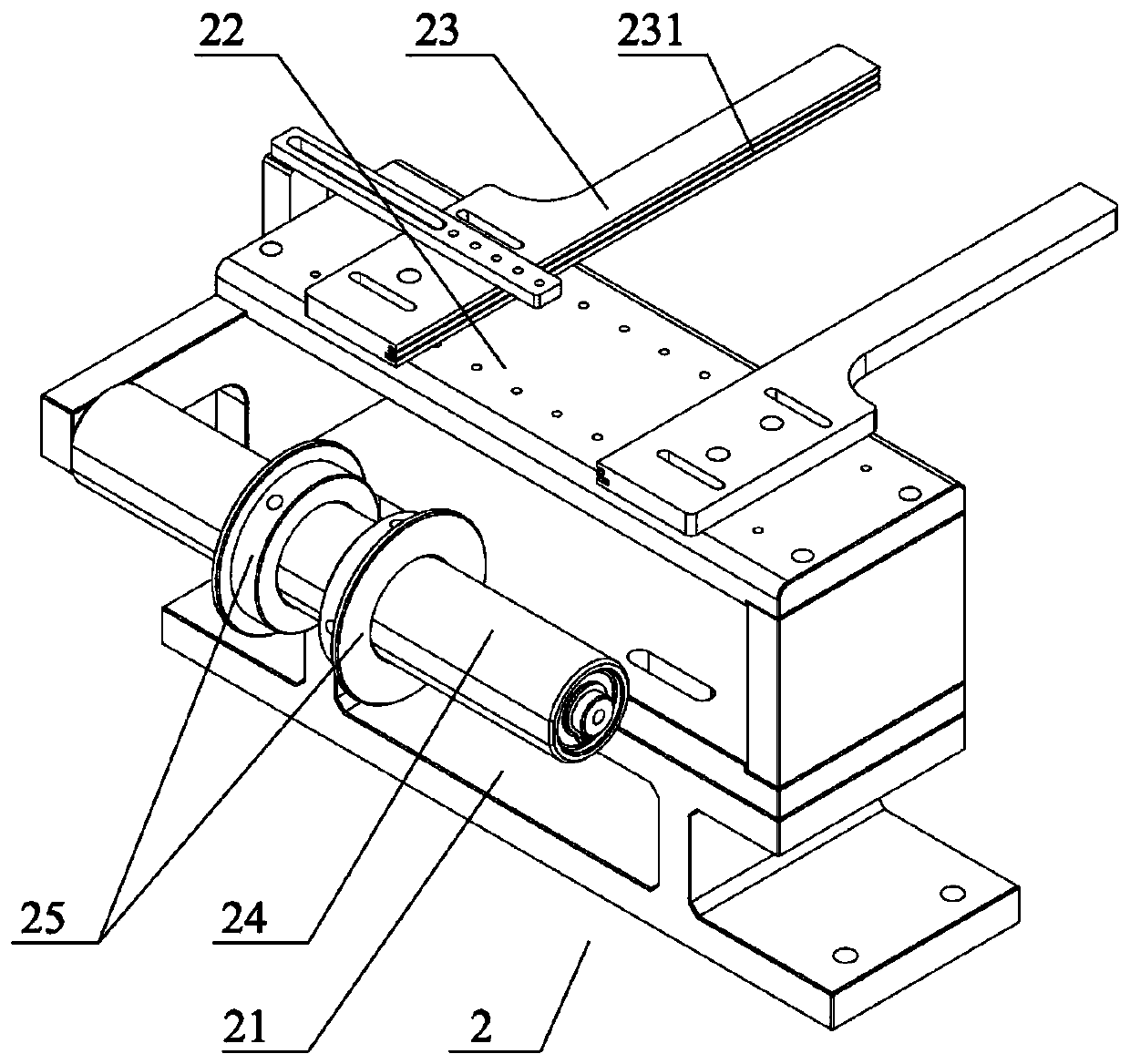

[0033] Such as Figure 1-8As shown, an automatic welding machine includes a frame 1, and the top of the frame 1 is usually provided with a working base plate. A laser welding device 5 is arranged above the device 3, and a first avoidance hole 301 corresponding to the laser welding device 5 is arranged on the stamping device 3, and the material pulling device 4 can pull the strip through the straightening device 2 and the stamping device 3 in turn. And the material pulling device 4, when the product processed and formed on the material belt is located in the first avoidance hole 301 on the punching device 3, the material pulling device 4 stops pulling the material, and the punching device 3 first positions and compresses the material belt passing through it, Then the laser welding device 5 above the stamping device 3 welds the product on the material strip in the first avoidance hole 301, and then the stamping device 3 cuts off the redundant connecting material point of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com