Visual inspection rear-end material receiving assembly line

A visual inspection and assembly line technology, applied in packaging automatic control, packaging, packaging protection and other directions, can solve the problems of reducing production efficiency, unable to accurately control feeding time, increasing labor costs, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

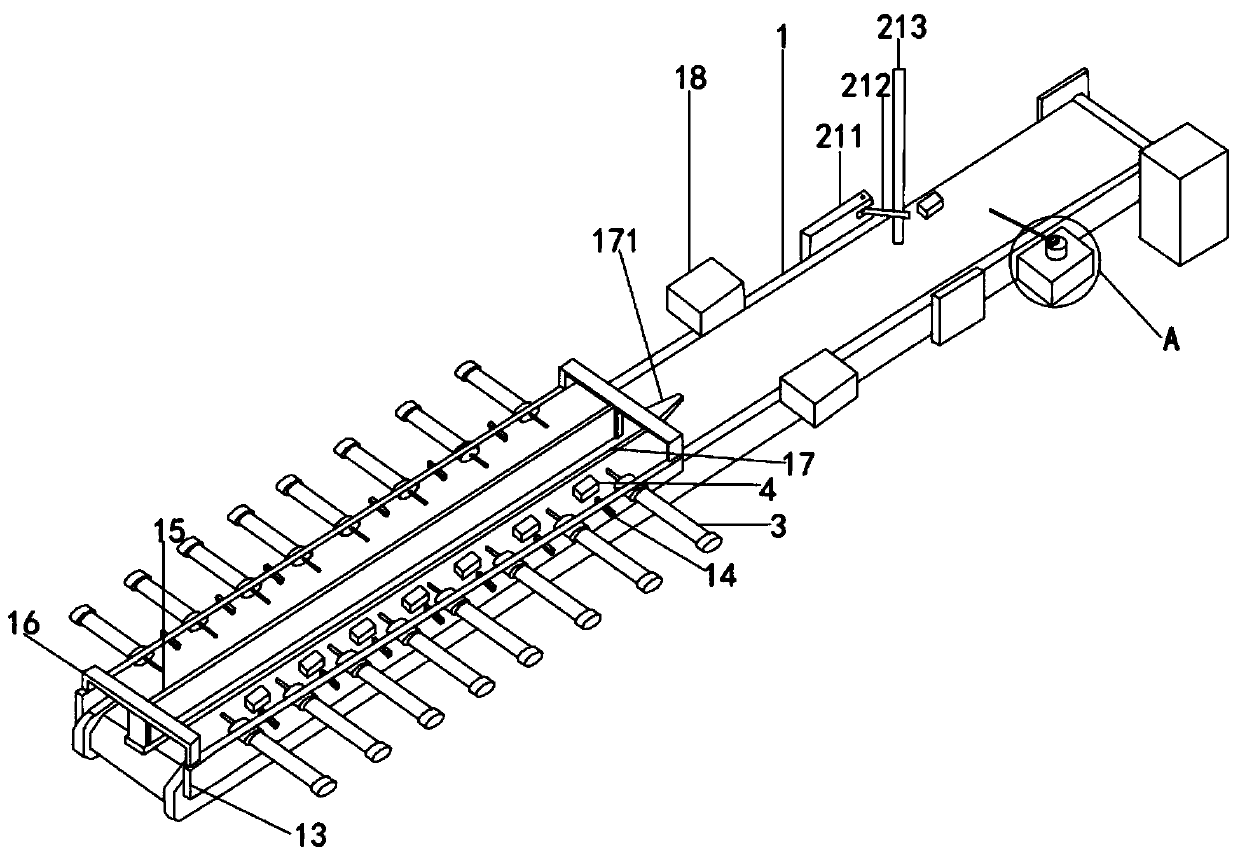

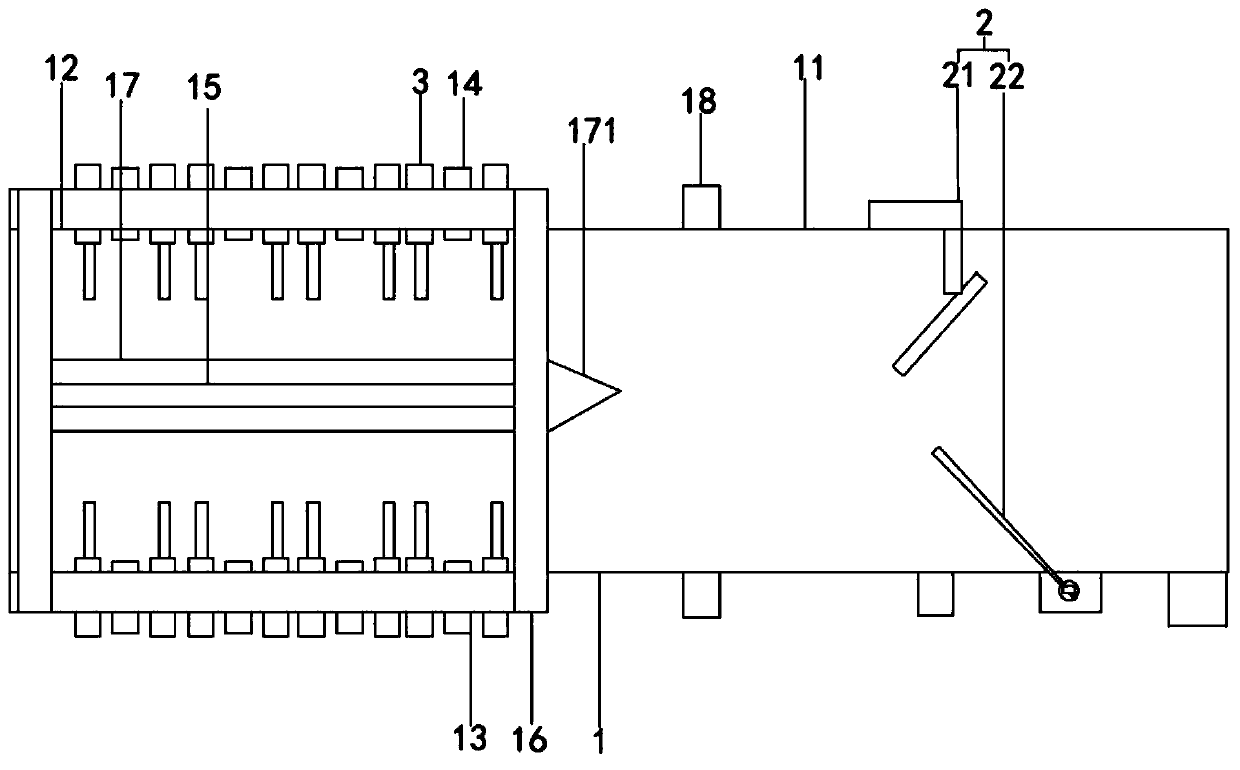

[0023] see Figure 1 to Figure 3 , the figure shows a visual inspection rear end material assembly line provided by the embodiment of the present invention. Firstly, the assembly line including the frame 1 and the frame 1 is set, and the separation area 11 and the positioning area 12 are set on the assembly line. , the positioning area 12 is located behind the separation area 11, the separation area 11 is provided with a separation mechanism 2, the separation mechanism 2 is used to separate the products 4 on the assembly line into the positioning area 12, the positioning area 12 is provided with a positioning mechanism 3, and the positioning mechanism 3 It includes a plurality of fixing parts 31 symmetrically arranged on both sides of the positioning area 12. The plurality of fixing parts 31 are equidistantly arranged in parallel along the length direction of the positioning area 12. There is a gap between adjacent fixing parts 3, and the product 4 is positioned in the gap. In...

Embodiment 2

[0029] see Figure 1 to Figure 3 , the figure shows a visual detection back-end material assembly line provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the positioning area 12 is set There is a baffle plate 15, the two ends of the baffle plate 15 are respectively provided with connecting seats 16, the connecting seats 16 are fixedly connected to the mounting plate 15, the bottom of the baffle plate 15 is provided with a dividing plate 17, and the dividing plate 17 is connected to the connecting seat 16 , the end of the lane divider 17 is triangular 171 . Through the setting of the above structure, it is possible to prevent the deviation of the product, limit the movement of the product, and ensure that the product is neat and orderly. At the same time, the connecting seat 16 is an "m"-shaped connecting seat. The movement of the assembly line, secondly, the ...

Embodiment 3

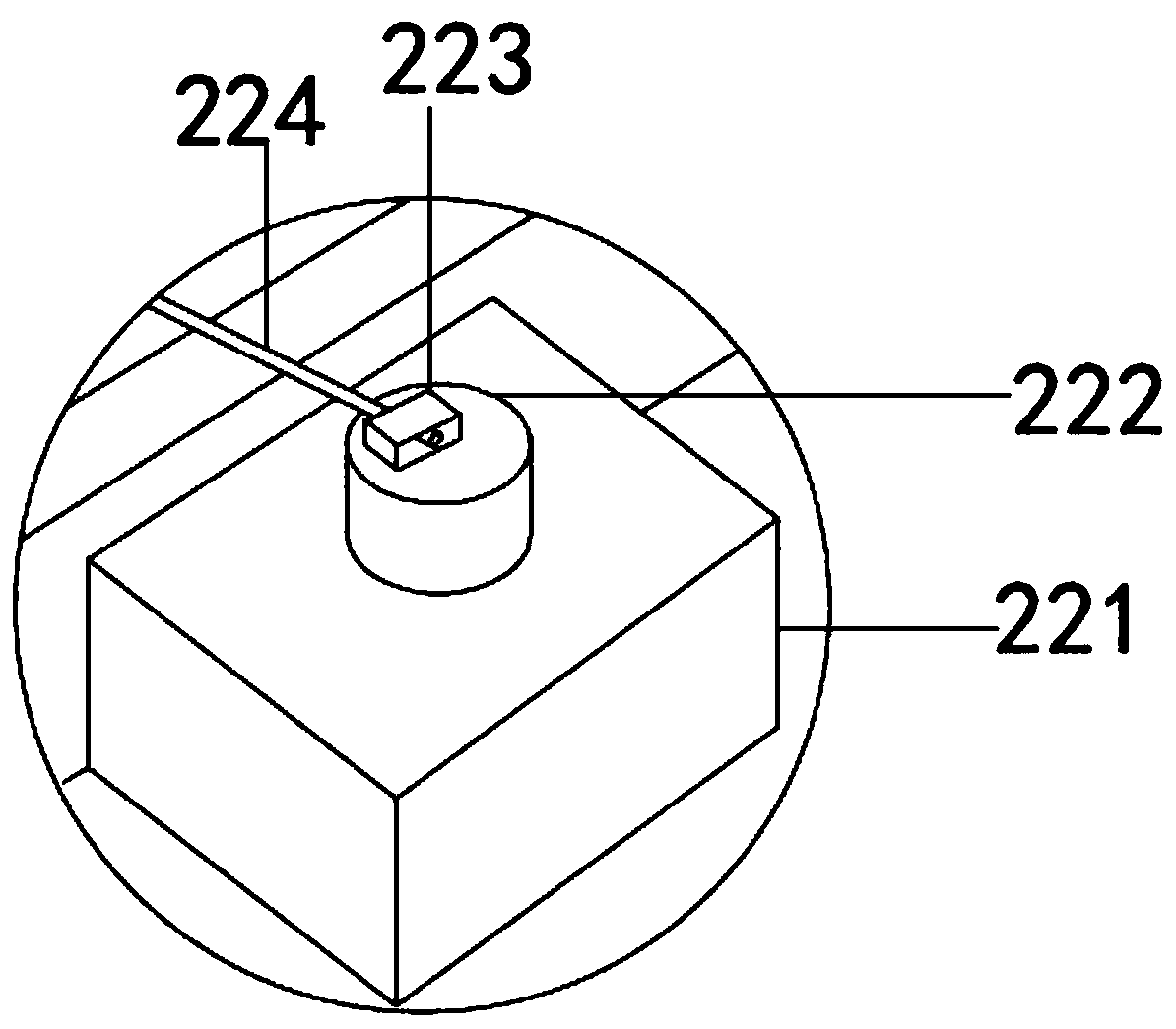

[0031] see Figure 1 to Figure 3 , the figure shows a visual inspection rear-end material assembly line provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiment, this embodiment further makes the following technical solutions as improvements: the separation mechanism 2 includes The first separation part 21 and the second separation part 22, the first separation part 21 and the second separation part 22 are respectively arranged on opposite sides of the separation area 11, and the first separation part 21 comprises a connecting plate fixedly connected on the frame 1 211, the connecting plate 211 is rotatably connected to the limit block 212, the opposite end of the limit block 212 is connected to the first separation rod 213, the second separation part 22 includes a second cylinder 221 fixedly connected to the frame 1, the second A circular turntable 222 is arranged on the cylinder 221, and the second cylinder 221 drives the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com