Drawing leveling dead space accurate measurement system and measurement method

An accurate measurement and dead zone technology, applied in textiles and papermaking, etc., can solve the problems of extensive, inability to adjust intuitively, and difficulty in sliver output, so as to improve sliver quality, good leveling effect, and efficient dead zone. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

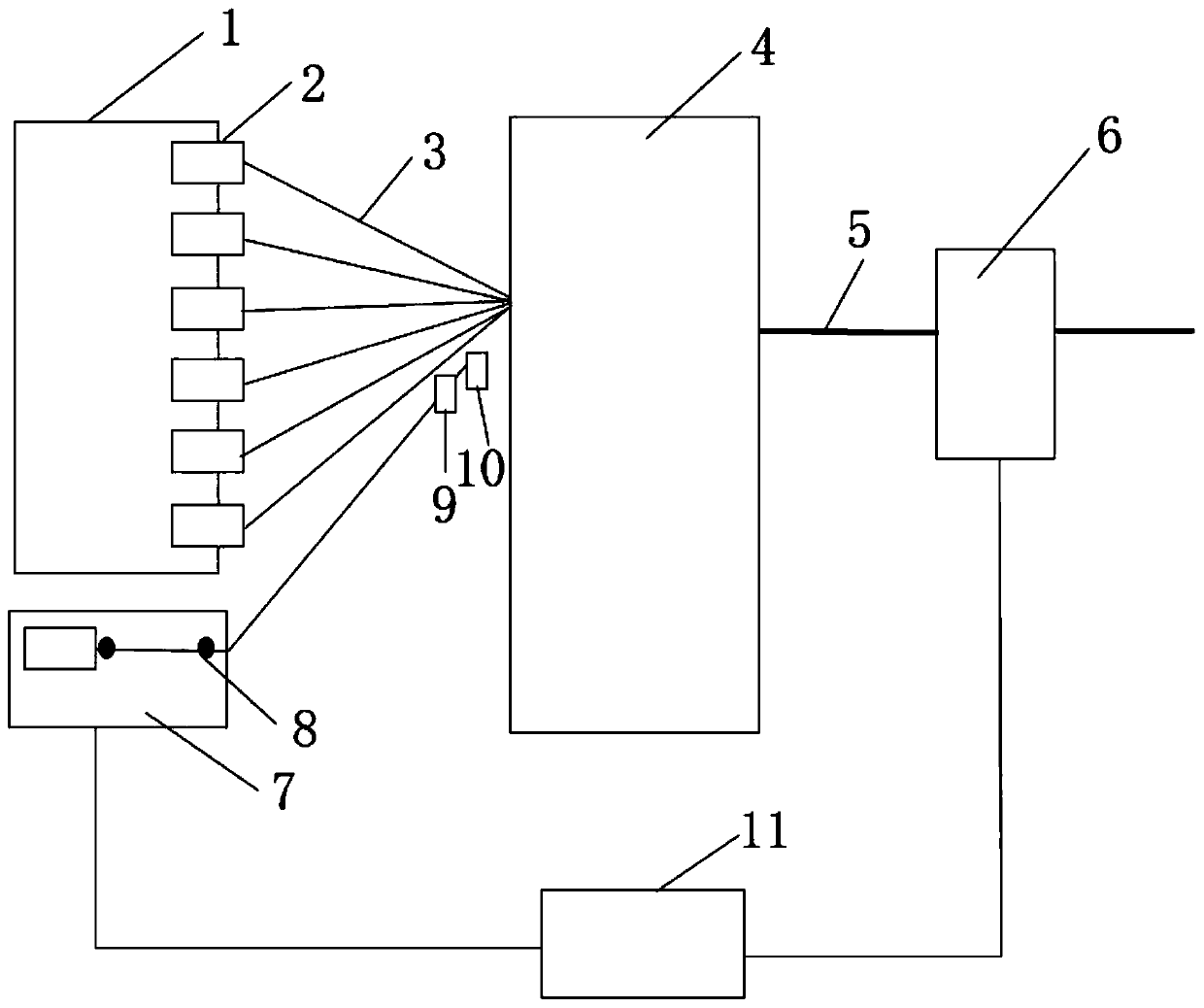

[0028] Such as figure 1 As shown, the accurate measurement system for the uniform dead zone of the draw frame includes a cotton-feeding introduction device 7, a cotton-feeding cutting device, a detection device 11, and a thickness measuring device 6, and the detection device 11 and the cotton-feeding cutting device and the thickness measuring device 6 are respectively The cotton input device 7 is connected with the cotton input cutting device, and the cotton input cutting device is located at the front end of the cotton input inlet of the draw frame 4 . The front end of the incoming cotton inlet of the draw frame is equipped with a leveling control system, which is used to record the thickness of the incoming cotton sliver. The leveling control system is also connected with the detection device.

[0029] The described cotton-feeding introduction device 7 is positioned at the can place device 1, and a plurality of cans 2 are placed on the can place device 1. In the present emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com