Yarn feeding nozzle of synthetic fiber fabric knitting machine

A synthetic fiber and knitting machine technology, applied in weft knitting, warp knitting, knitting, etc., can solve the problems of knitting machines that cannot be applied to various specifications, cannot meet the knitting production requirements of various synthetic fiber fabrics, and have single functions. , to achieve the effect of automatic remote adjustment of yarn tension, improvement of yarn guiding effect, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

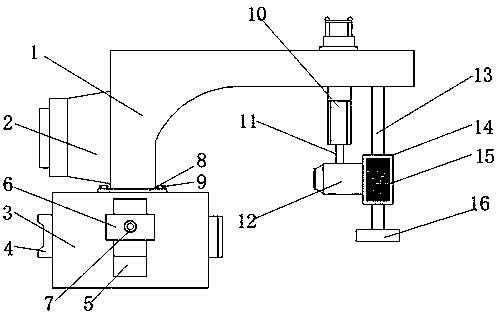

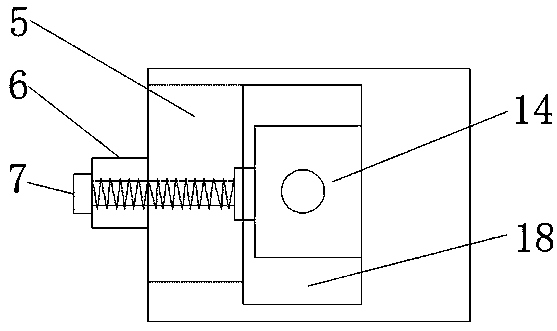

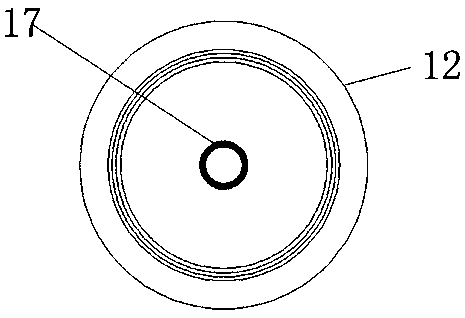

[0020] like Figure 1-3 The shown yarn feeder of a synthetic fiber fabric knitting machine includes a bracket 1, the lower end of the bracket 1 is connected with a housing 3, the inside of the housing 3 is provided with a yarn feeding head 4, and the inside of the housing 3 is provided with a second A slide rail 5 and a chute 18, the chute 18 communicates with the first slide rail 5, the yarn feeding head 4 is installed in the chute 18, the yarn feeding head 4 can move up and down in the chute 18, thereby adjusting the yarn feeding head The position of 4 makes it suitable for knitting machines of different specifications, and has a high degree of adaptability. The first slide rail 5 is connected with a first fixing bolt 7 inside, and the first fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com