Design method, support structure and construction method of gob-side entry retaining support structure

A support structure and design method technology, applied in mining equipment, earth square drilling, ceramic products, etc., can solve problems such as collapse damage, filling wall structure instability, difficulty in ensuring the connection density of material junctions, etc., to ensure Integrity, reducing the risk of gas accumulation, and the effect of preventing dynamic pressure shock disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

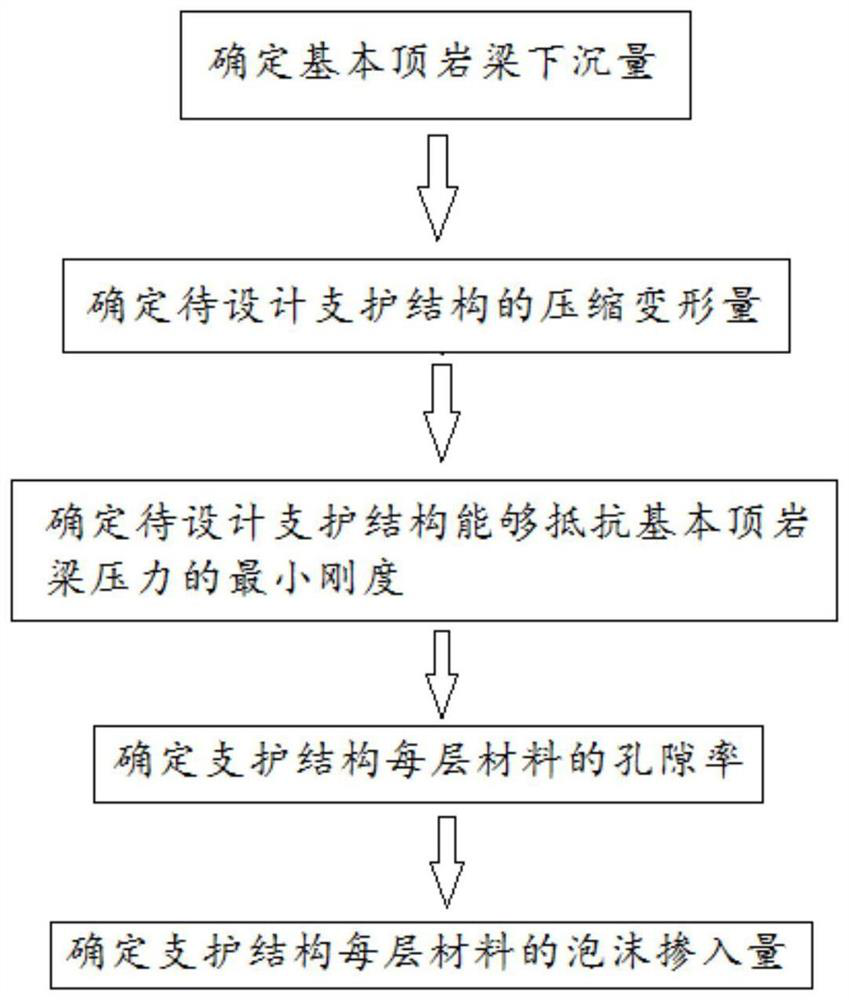

Method used

Image

Examples

Embodiment 2

[0113] This embodiment discloses a gob-side retaining structure, which is designed using the design method described in Embodiment 1, and is formed by pouring fiber-reinforced foam concrete layer by layer, and the amount of foam to be mixed in each layer is based on the design method to obtain.

Embodiment 3

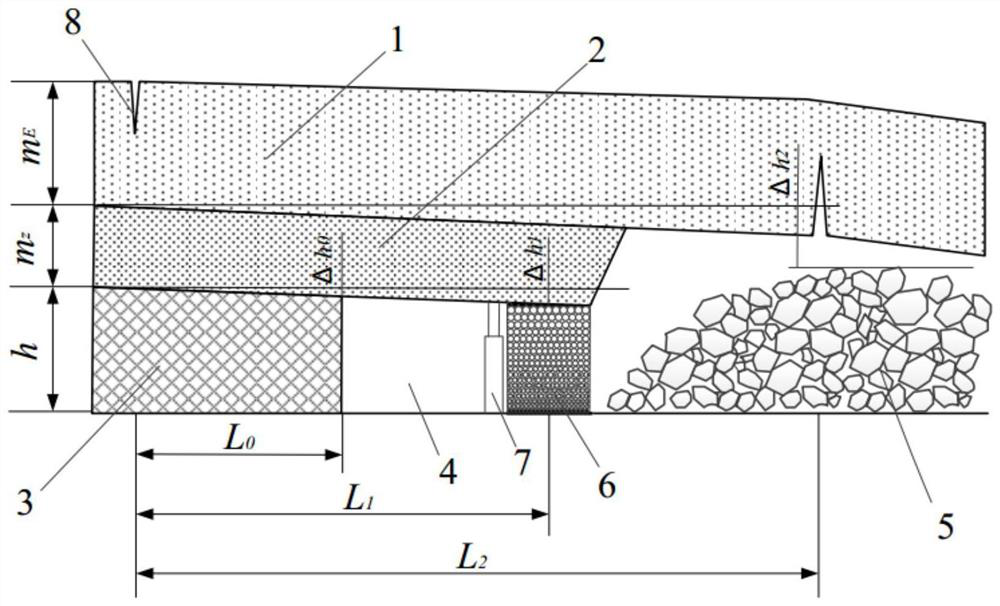

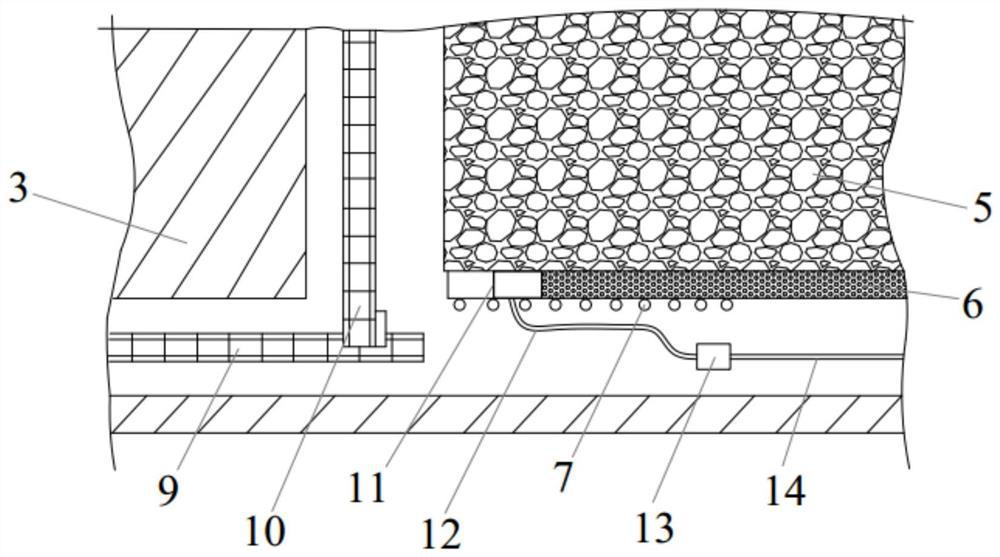

[0115] This embodiment discloses a construction method for the side support structure of gob-side entry retaining, such as Figure 2-4 shown, including the following steps:

[0116] Step 1: Arranging a plurality of hydraulic props 7 in the roadway, the top surface of the hydraulic props is in contact with the direct roof and the bottom surface to support the direct roof and the basic roof.

[0117] The hydraulic prop adopts a hydraulic jack, and its arrangement direction is perpendicular to the working face of the coal wall, and is located on the gangue side.

[0118] Step 2: pouring the gob-side retaining structure with fiber-reinforced foam concrete at the position between the gangue and the hydraulic prop.

[0119] Specifically, the preparation of fiber-reinforced foamed concrete is carried out on the ground. The preparation method is: 45# cement, fly ash and gypsum are mixed according to a set ratio to form a dry mix, and then mixed with polypropylene fibers to form a pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com