LED lamp bulb shell, LED lamp and machining method thereof

A technology of LED light bulbs and LED lamps, which is applied in the field of lighting, can solve the problems of poor lighting decoration effects, achieve the effects of uniformity and diversity, and enhance luminous and light guiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

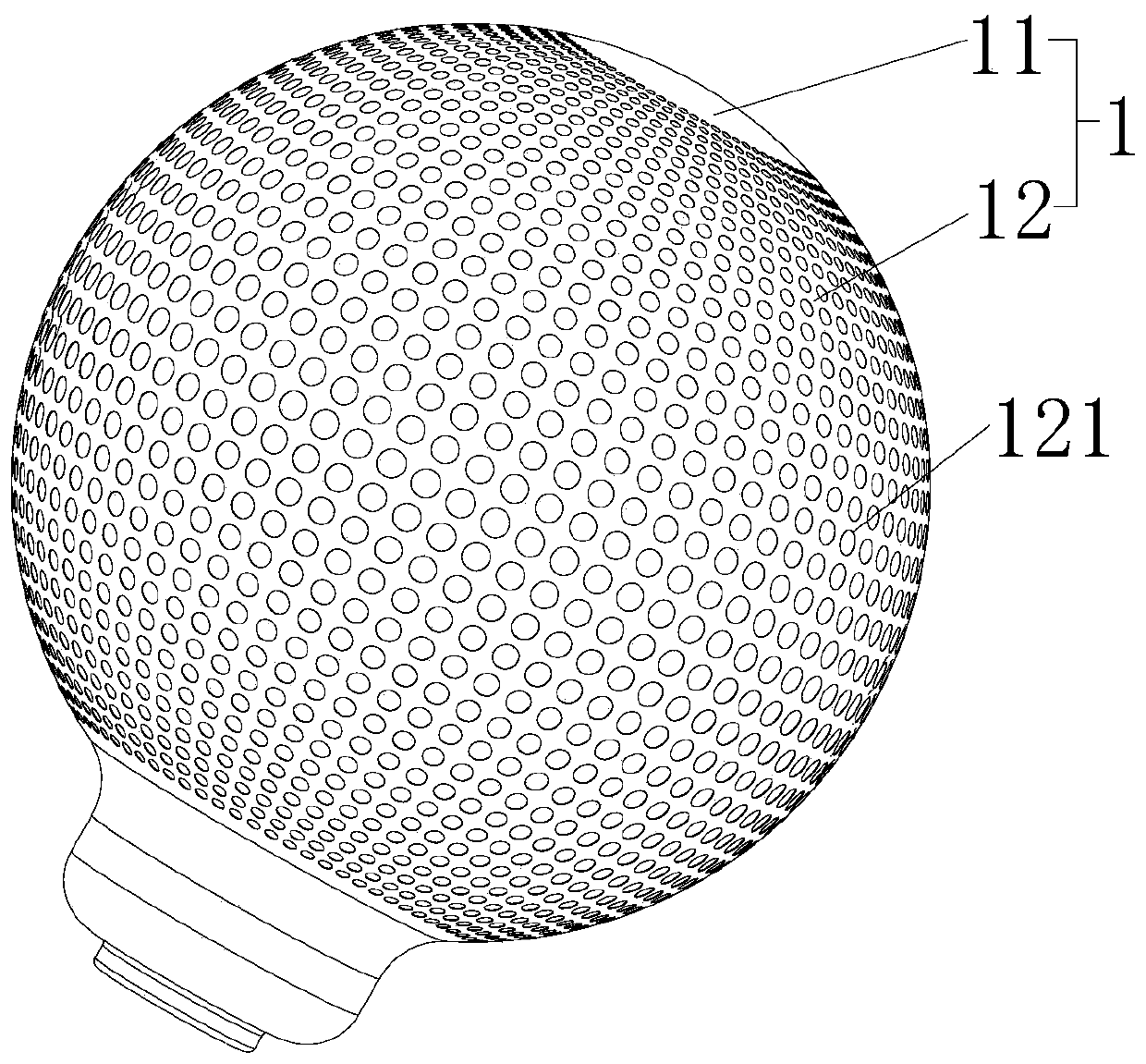

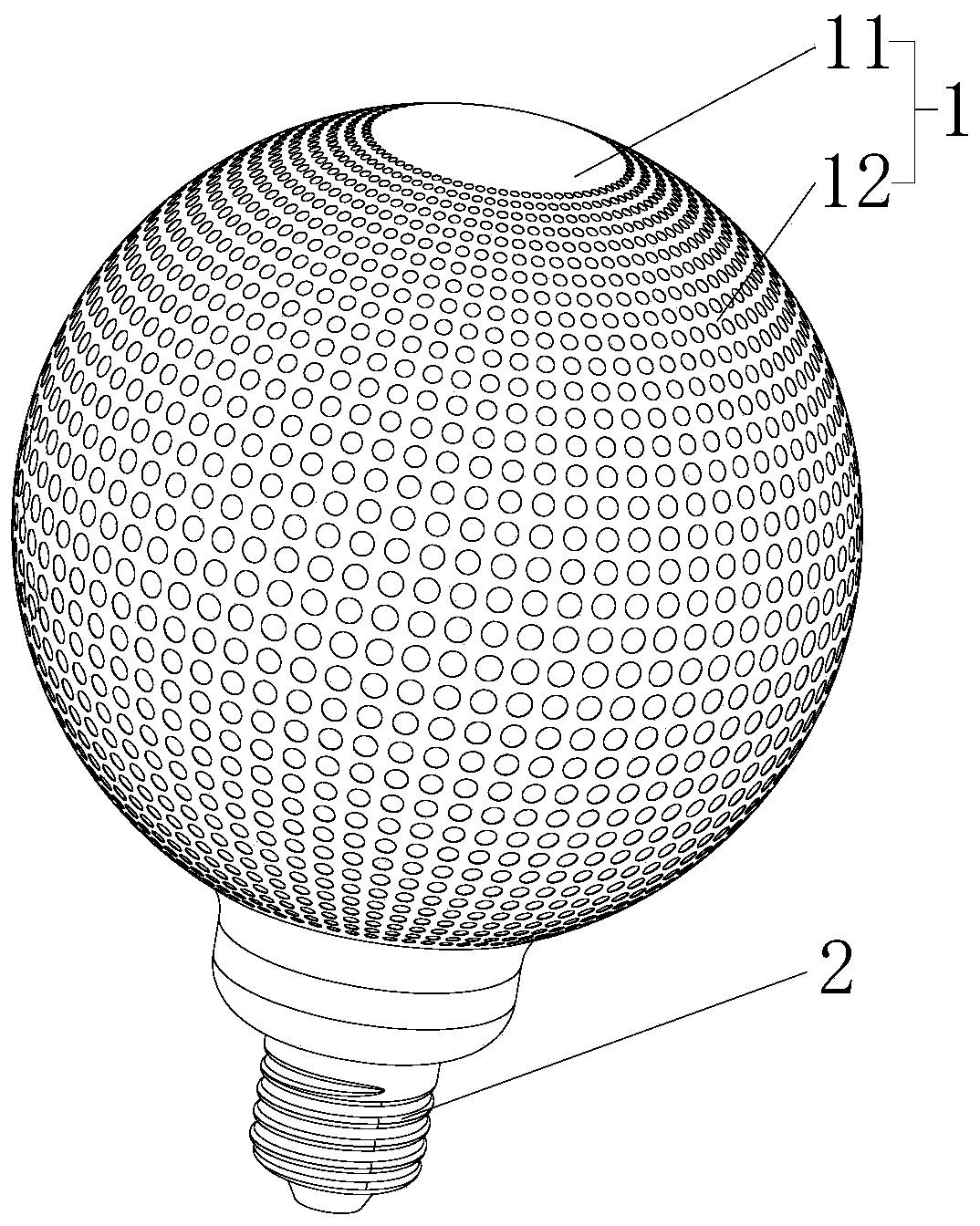

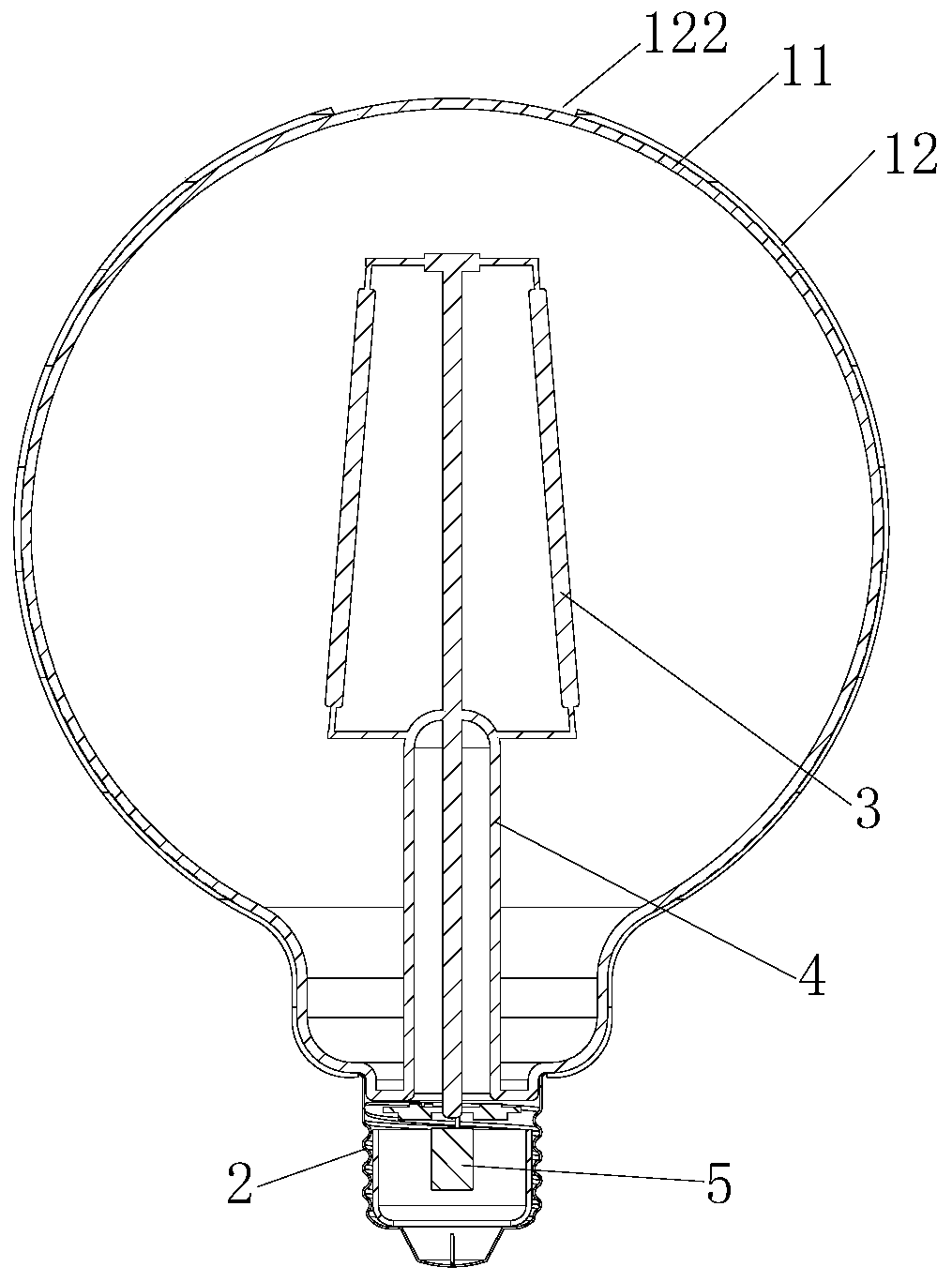

[0030] Such as Figure 1-4 As shown, this embodiment provides a LED light bulb bulb, including a bulb body 11 and a film 12, the bulb body 11 is transparent, and the film 12 is arranged on the inner surface and / or outer surface of the bulb body 11, The film 12 is laser engraved with engravings 121 .

[0031] The bulb body 11 has an installation opening, and an accommodating space is formed in the bulb body 11, which can be used to accommodate the illuminant 3. In this embodiment, the bulb body 11 has a single-layer structure. The film 12 covers the inner surface and / or the outer surface of the bulb body 11 . The film 12 extends from the installation opening of the bulb body 11 to the top of the bulb body 11 . The film 12 has an opening 122 opposite to the installation opening. Through the opening 122 provided at the top, the light can be emitted from the top to ensure the amount of light emitted from the top. Such as image 3 As shown, the membrane 12 is arranged on the out...

Embodiment 2

[0045] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that in the LED light bulb bulb shell 1 of this embodiment, the bulb shell body 11 has a double-layer structure, and the bulb shell body 11 includes an inner bulb shell 111 and an outer bulb shell 112 , the outer bulb 112 covers the outside of the inner bulb 111 . The membrane 12 may be provided on the inner and / or outer surface of the inner bulb 111 and / or the outer bulb 112 . When at least two layers of films 12 are provided, the carvings 121 on the two layers of films 12 are overlapped along the direction of light to ensure light transmission, and the openings 122 of at least two layers of films 12 are also overlapped along the direction of light.

[0046] The LED lamp of this embodiment is basically the same as that of Embodiment 1, the only difference is that both the inner bulb 111 and the outer bulb 112 are connected to the lamp cap 2, the inner bulb 111 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com