Rapid leveling method for surveying instrument tripod

A technology of tripod and instrument triangle, which is applied in the field of tripod of surveying and plotting instruments, can solve the problems of low accuracy, influence of measurement stability, long adjustment process time, etc., and achieve the effect of high balance control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

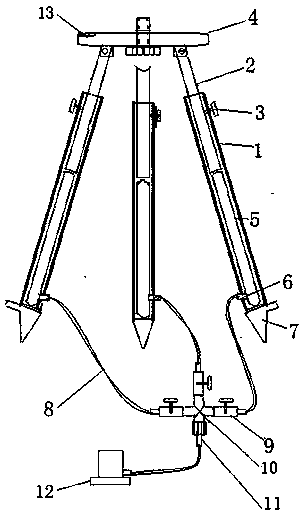

[0015] like figure 1 As shown, a method for quick leveling of the tripod bracket of the surveying instrument is to install an airbag support device on the tripod bracket of the surveying instrument; The structure is that the three mouth pipes of the four-way pipe 10 are respectively connected to the gate valve 9, and each gate valve 9 is respectively connected to the ventilation hose 8, and the other nozzle of the four-way pipe 10 is connected to the upper valve 11; the specific leveling steps Yes:

[0016] In the first step, at first drill through holes at the bottom of the three leg sleeves 1 of the tripod, install the above-mentioned three telescoping bags 5 in the inner cavities of the three leg sleeves 1 respectively, and make each The air inlet 6 of the telescoping bag 5 is exposed from the corresponding through holes respectively, and is for standby;

[0017] In the second step, during on-site surveying and mapping work, loosen the fastening screws 3 on the three legs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com