Acoustic emission sensor fixing device and using method thereof

A technology of acoustic emission sensor and fixing device, which is applied in the direction of material analysis using acoustic emission technology, measuring devices, and material analysis using sound waves/ultrasonic waves/infrasonic waves, etc. To meet the needs of practical applications and other issues, to achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

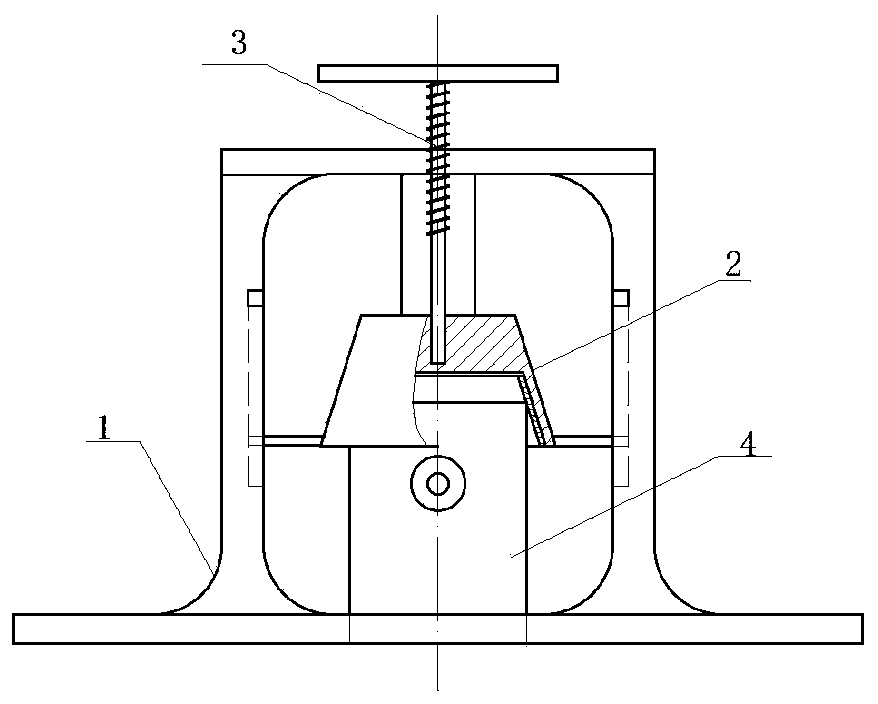

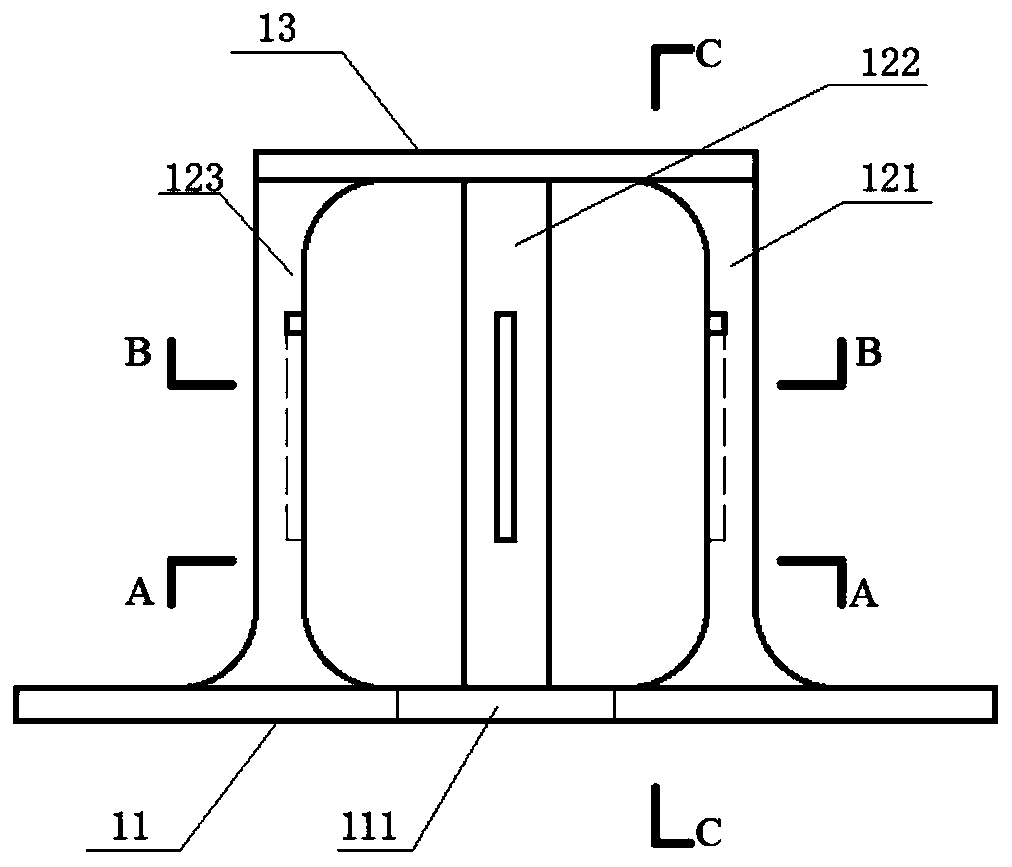

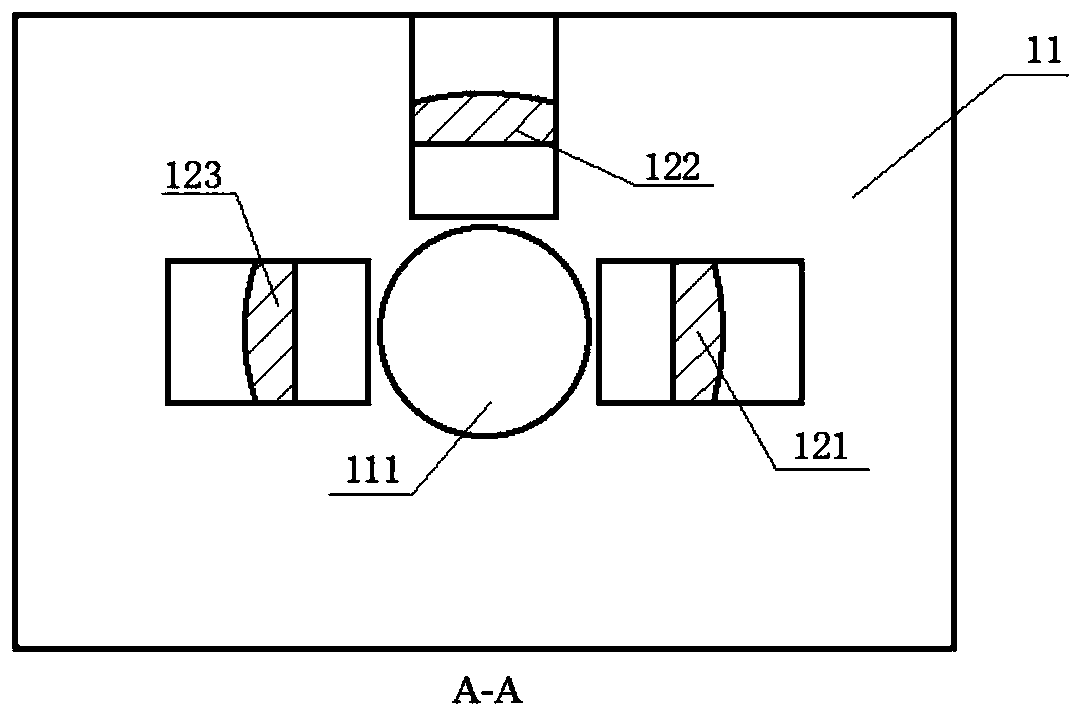

[0027] like Figure 1~5 As shown, the acoustic emission sensor fixing device includes a base frame 1, a gland 2, and an adjusting bolt 3. The adjusting bolt 3 passes through the top of the base frame 1 and is connected to the gland 2. The base frame 1 is provided with a mounting hole 111 for limiting the acoustic emission. The installation position of the sensor 4, the gland 2 is in the shape of a hollow circular platform, and the adjusting bolt 3 exerts force on the gland 2, so that the acoustic emission sensor 4 is closely attached to the surface of the test piece, and the gland 2 can position the acoustic emission sensor 4 in the circumferential direction. Restricted, the base frame 1 includes a base 11, a vertical plate 12 installed on the base 11 and a top plate 13 covered on the vertical plate 12, the base 11 is provided with a mounting hole 111 for fixing the acoustic emission sensor 4, and the vertical Plate 12 comprises right vertical plate 121, back vertical plate 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com