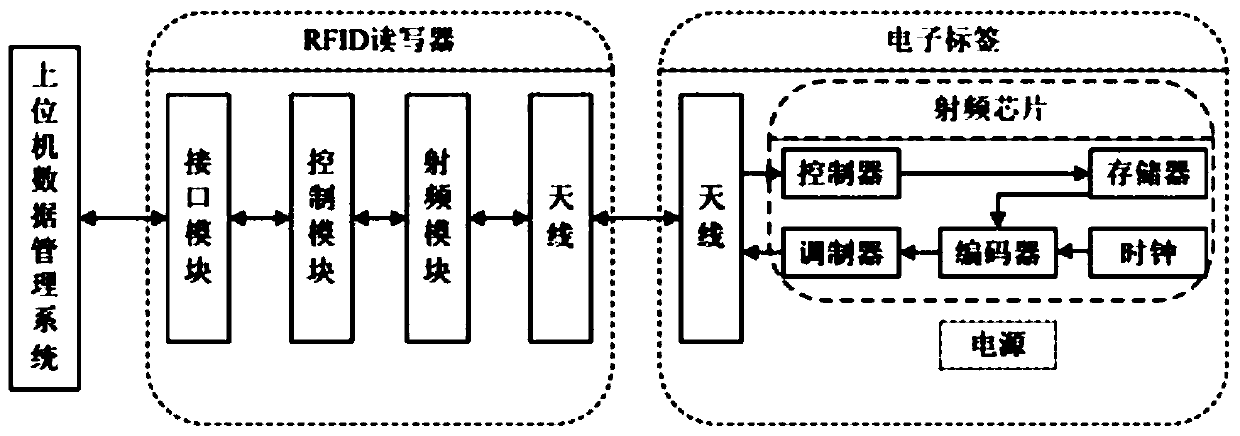

Dangerous goods management system and method based on RFID

A technology of management system and management method, which is applied in the direction of cooperative devices, instruments, computer parts, etc., can solve problems such as high cost and identification error, and achieve the effects of improving accuracy, ensuring integrity, and reducing the cost of radio frequency monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

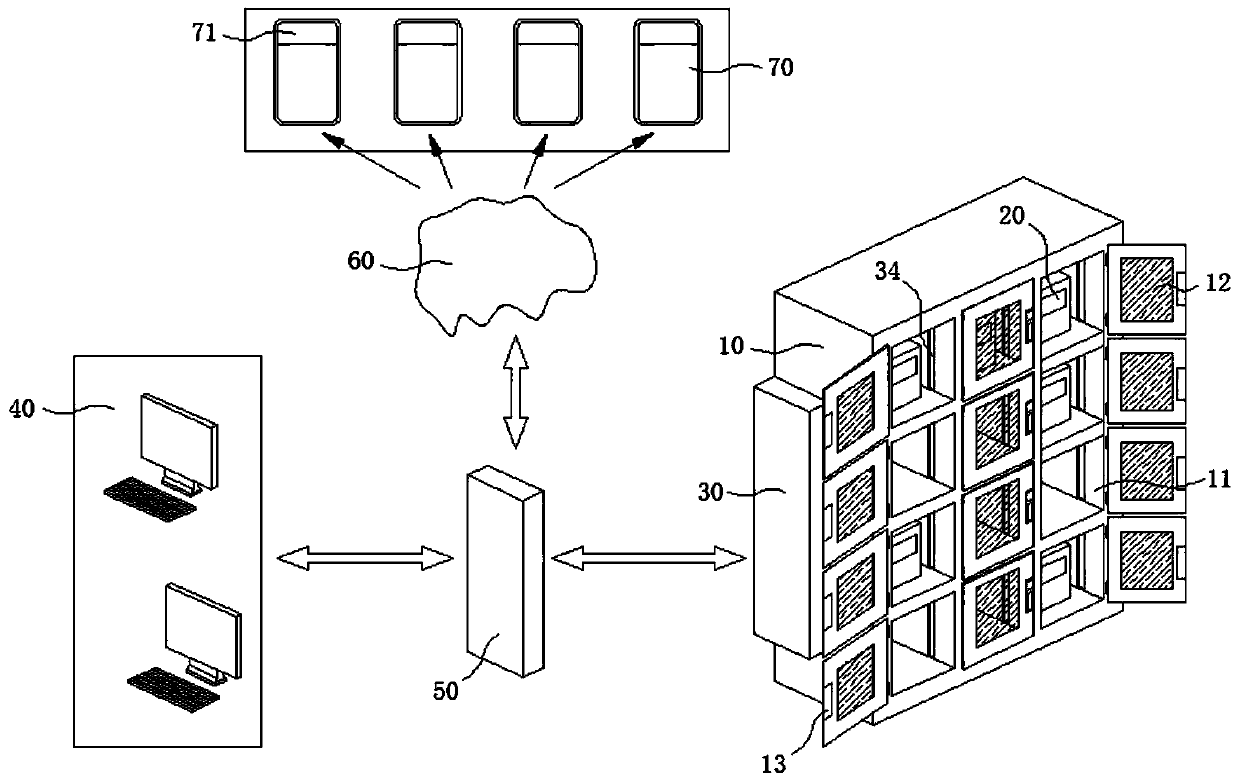

[0044] This embodiment provides an RFID-based dangerous goods management system, please refer to figure 2 As shown, it is a schematic structural diagram of the management system, including an isolation storage cabinet 10, a dangerous goods label 20, a reading and writing device 30, a PC upper computer 40, a LAN switch 50, a cloud platform 60 and a mobile terminal 70;

[0045] in:

[0046] The isolated storage cabinet 10 is a metal cabinet, and there are multiple independent storage chambers 11 inside the cabinet body. Each independent storage chamber 11 stores a dangerous article independently, and the independent storage chambers 11 are equipped with airtight doors 12 to realize the safety of dangerous goods. Closed storage of goods; on the airtight door 12, a combination lock 13 is installed to realize encrypted storage of dangerous goods.

[0047] The dangerous goods label 20 adopts a low-power, ultra-high frequency RFID radio frequency label, which is packaged or pasted ...

Embodiment 2

[0058] This embodiment provides an RFID-based dangerous goods management method, please refer to Figure 7 As shown, it is a flow chart of the management method, including:

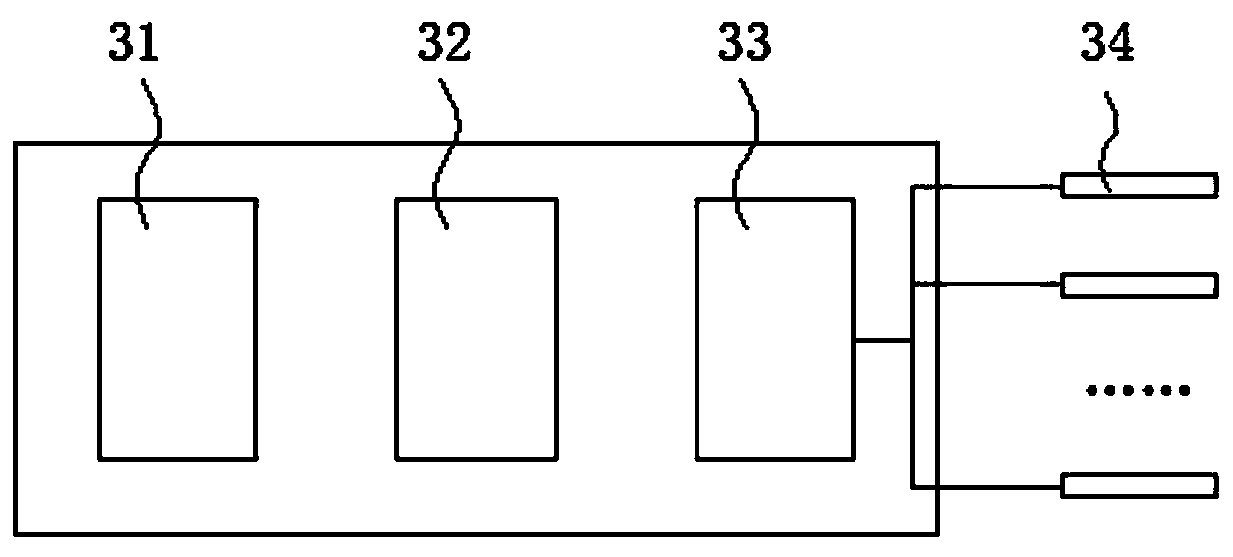

[0059] S1. Based on the reader-writer 33, a plurality of coupling antennas 34 are sequentially addressed and accessed, and the coupling antenna 34 is coupled with the dangerous goods label 20 to obtain address data; in the process of obtaining the address data, the coupling antenna 34 and the dangerous goods label The coupling can be completed under the condition of low power between 20. The principle is: in the closed metal isolation storage cabinet, the radio frequency signal sent by the coupling antenna will be reflected, so that the radio frequency signal will be enhanced, thus ensuring the smooth operation of the coupling antenna. Coupling with dangerous goods labels to achieve accurate detection results. Compared with the traditional high-power coupling, the cost is lower, and there will be no iden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com