Electric connector and manufacturing method thereof

A technology of an electrical connector and a manufacturing method, applied in the direction of connection, elastic body connector, parts of the connecting device, etc., can solve the problems of deformation of the body, affecting the use of the electrical connector, and the electrical connector cannot guarantee the electrical connection, etc. Achieve the effect of not easy to deform and easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0058] The manufacturing method of the second embodiment includes the following steps:

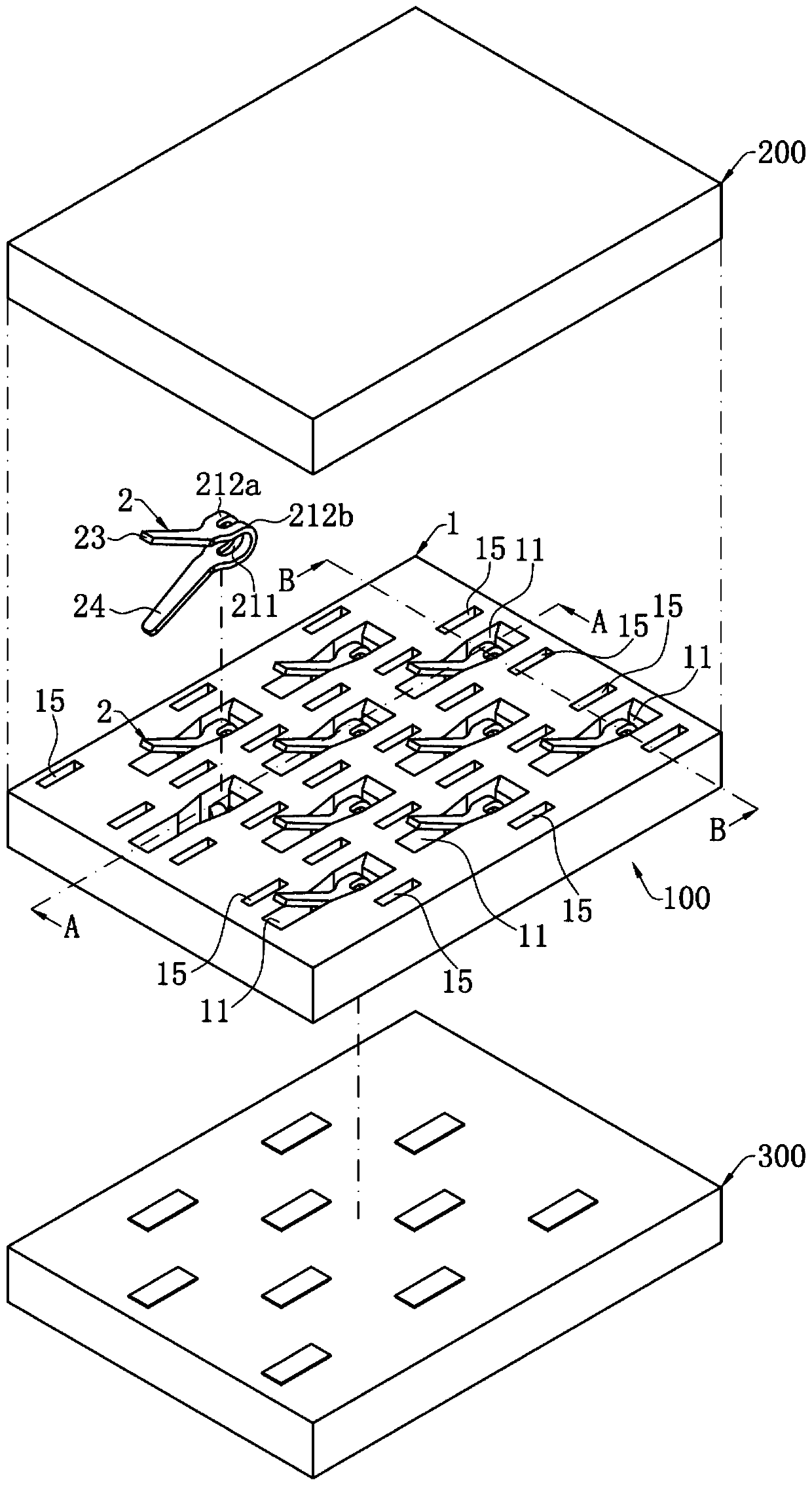

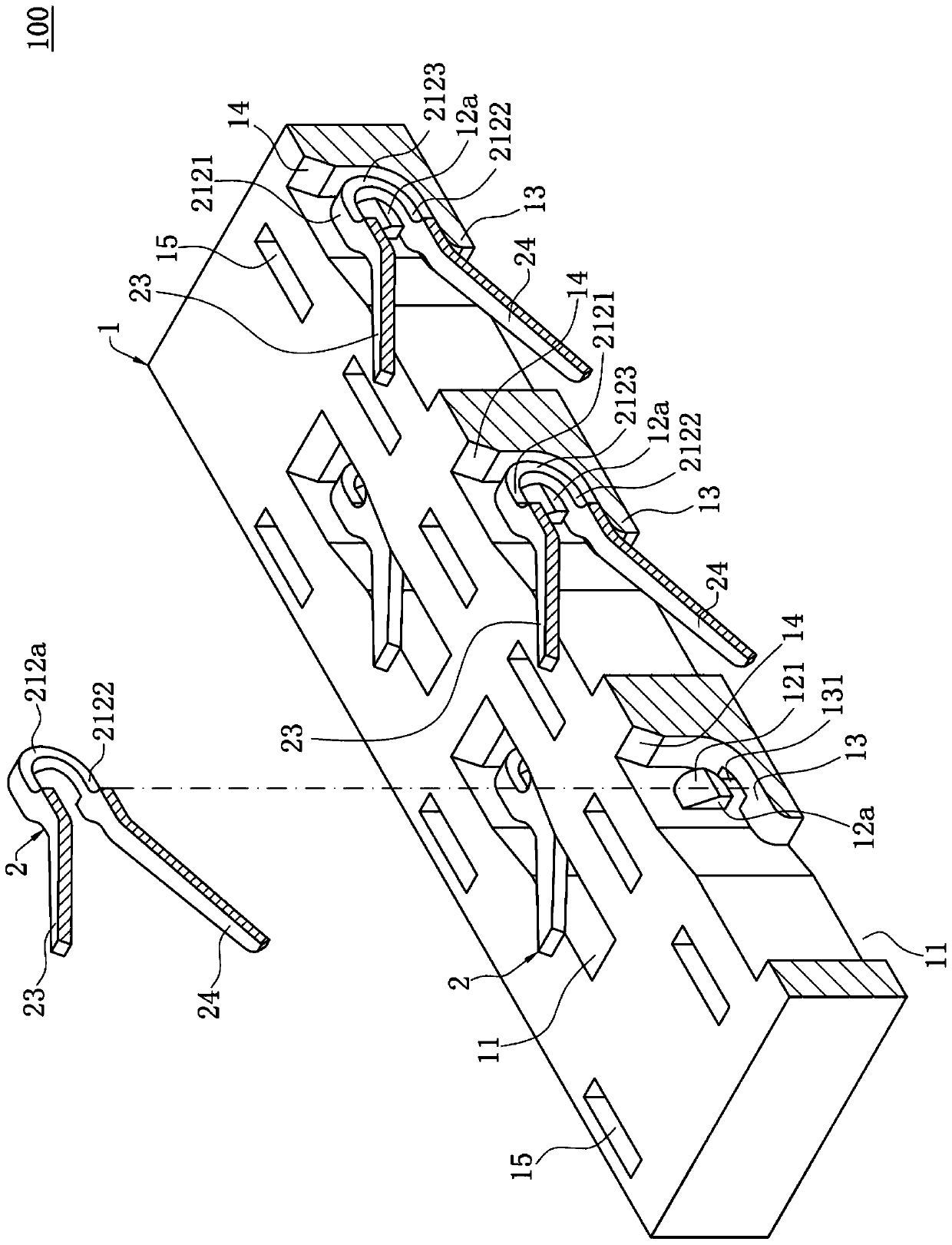

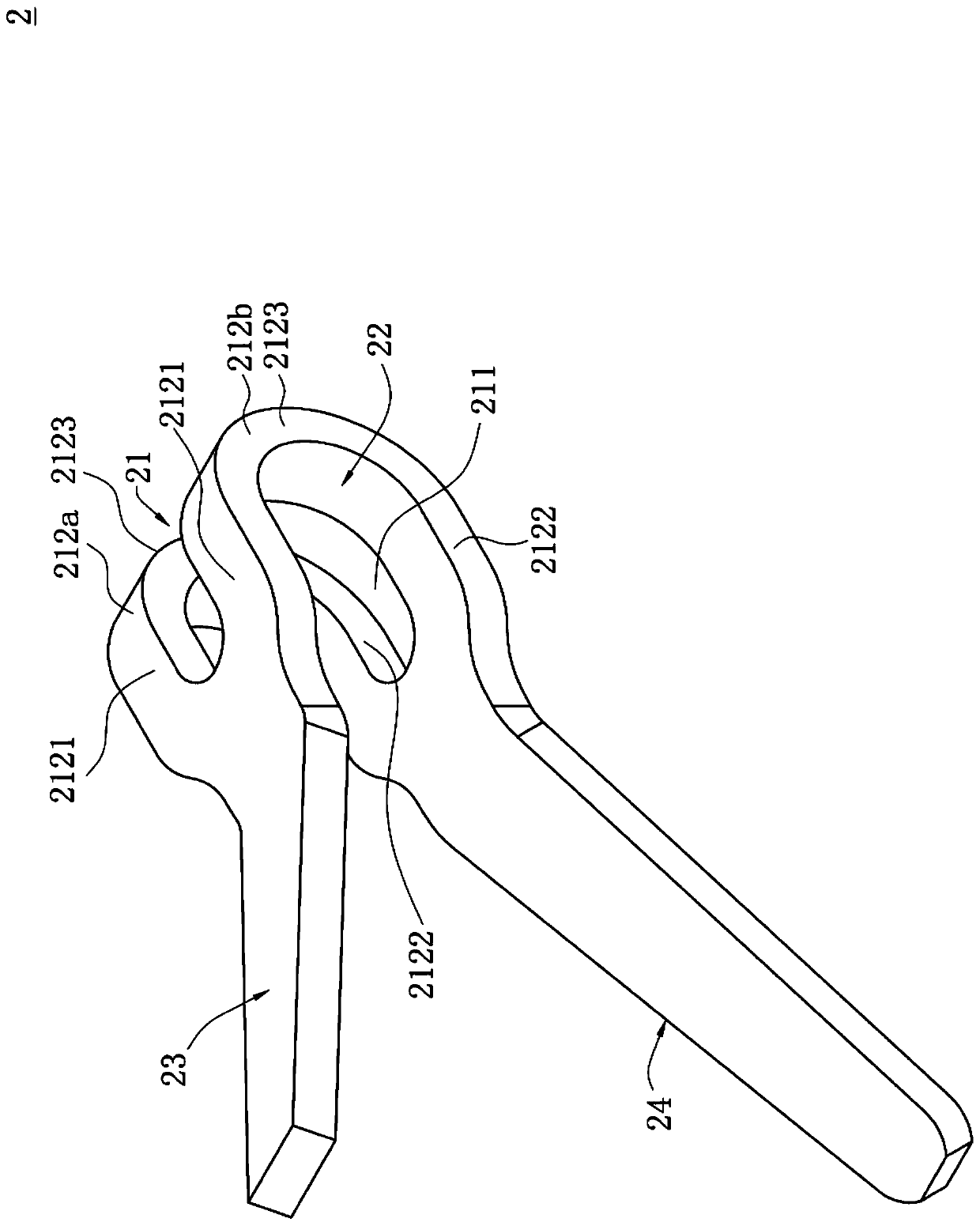

[0059] S1: if Figure 7 and Figure 8 As shown, the body 1 is provided, the lower edge of the first bump 12a and the lower edge of the second bump 12b (not shown) are arc-shaped, and a plurality of conductive terminals 2, each The upper elastic arm 23 of the conductive terminal 2 is connected to a material strip 400;

[0060] S2: if Figure 8 and Figure 9 As shown, the conductive terminal 2 whose receiving space 22 is opened upwards is inserted into the receiving hole 11 through the material strip 400, and the connecting section 2123 of the first branch 212a passes through the first protrusion downwards. block 12a, and is abutted by the first bump 12a, the connecting section 2123 of the second branch 212b passes down the second bump 12b, and is abutted by the second bump 12b connected, so that the first branch 212a and the second branch 212b are deformed closer to the through groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com