A general-purpose cooling enclosure

A cooling machine, a general-purpose technology, applied in the direction of cooling/ventilation devices, casings/covers/supports, electromechanical devices, etc., can solve the problems of natural cooling, air-cooling conversion, complicated manufacturing process, high cost, etc., to achieve cooling Diversified methods, simple and convenient disassembly and assembly, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

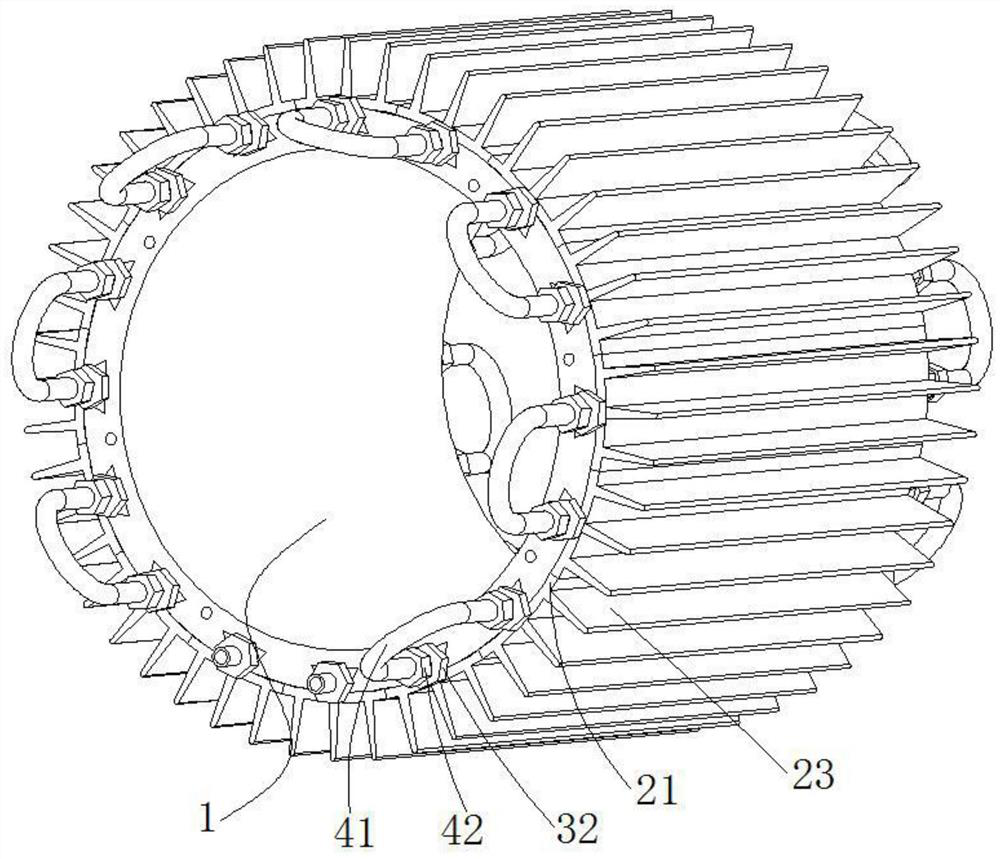

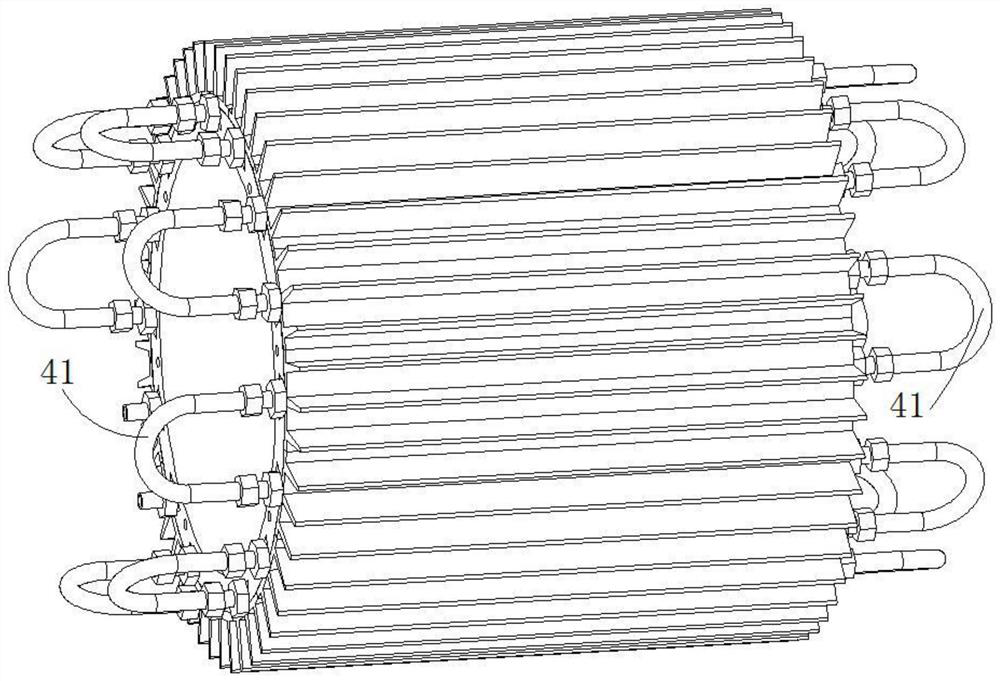

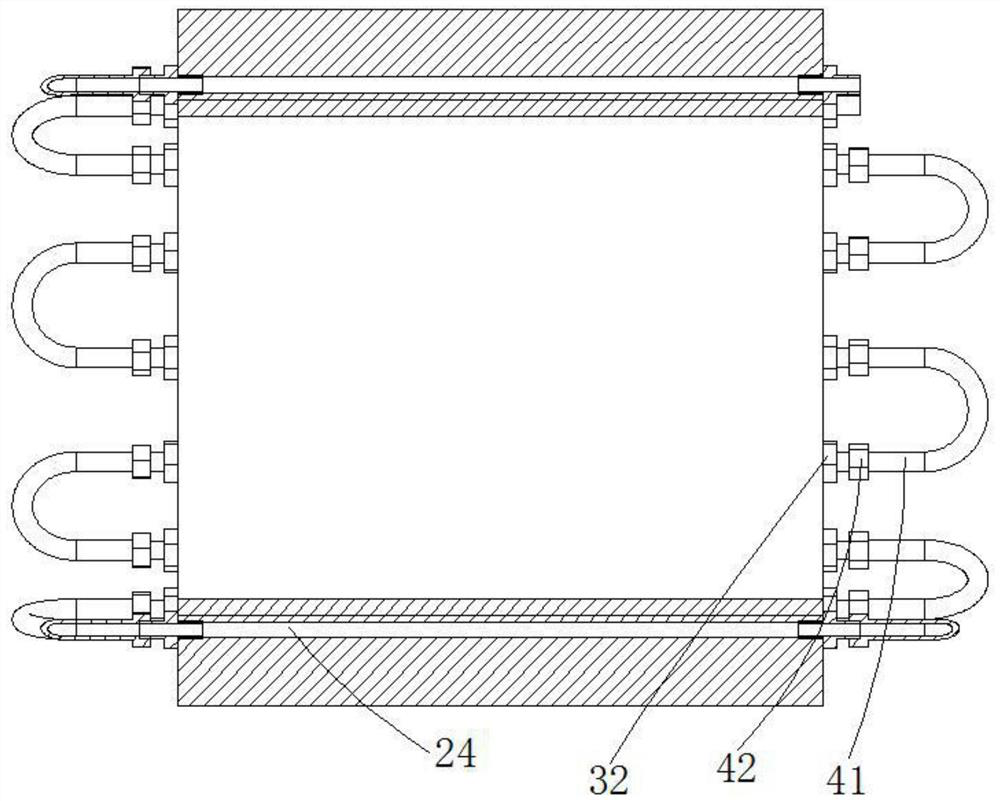

[0025] Such as Figure 1 to Figure 7 As shown, a general-purpose cooling casing includes a cylindrical shell 1 and inserts 2 uniformly distributed on the annular outer wall of the shell 1 in the circumferential direction. The material of the shell 1 is steel, and the material of the insert 2 is aluminum. The shell 1 It is a two-end through structure.

[0026] The insert 2 includes fins 23, which are cooling ribs. The insert 2 includes an arc-shaped plate 21 , the inner wall of the arc-shaped plate 21 fits the annular outer wall of the housing 1 , that is, the arc size of the inner wall of the arc-shaped plate 21 matches the arc shape of the outer wall of the housing 1 . The fins 23 are disposed on the outer wall of the arc-shaped plate 21 .

[0027] The side walls of the arc-shaped plates 21 of two adjacent inserts 2 are attached to each other, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com