Tank body high-temperature-resistant spongy ceramic filter

A ceramic filter, ceramic filtration technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve problems such as irregularity, speed reduction, liquid purity influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 To attach Figure 5 Shown:

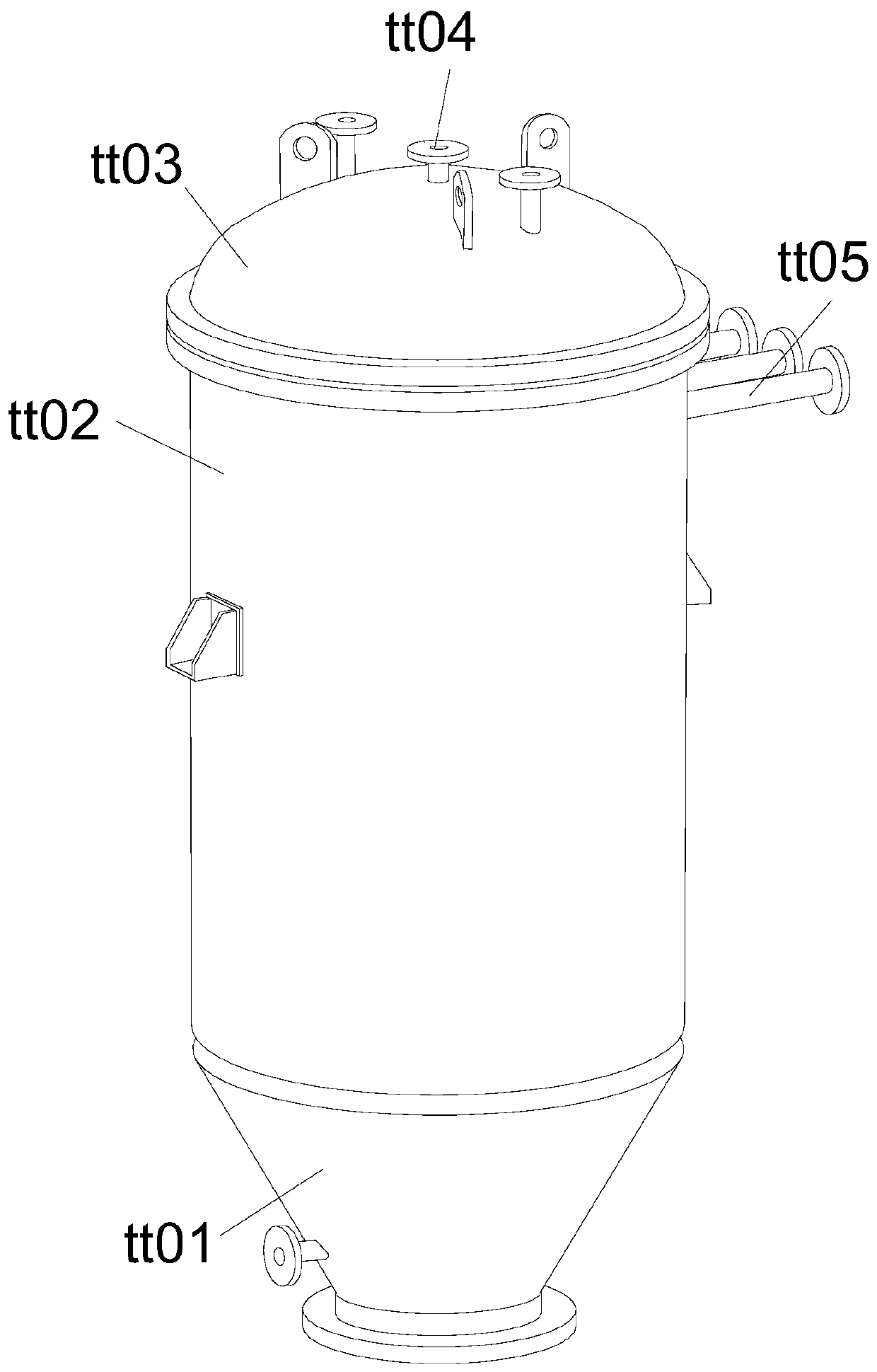

[0031] The invention provides a high-temperature-resistant sponge-shaped ceramic filter with a tank body, the structure of which includes a material delivery port tt01, a central control tank tt02, a top cover tt03, a ventilation port tt04, and a ceramic filter port tt05.

[0032] The upper surface of the material delivery port tt01 is connected to the lower surface of the central control tank tt02, the end of the central control tank tt02 away from the material delivery port tt01 is connected to the top cover tt03, and the vent tt04 runs through the top cover tt03 Inside, the ceramic filter port tt05 communicates with the central control tank tt02.

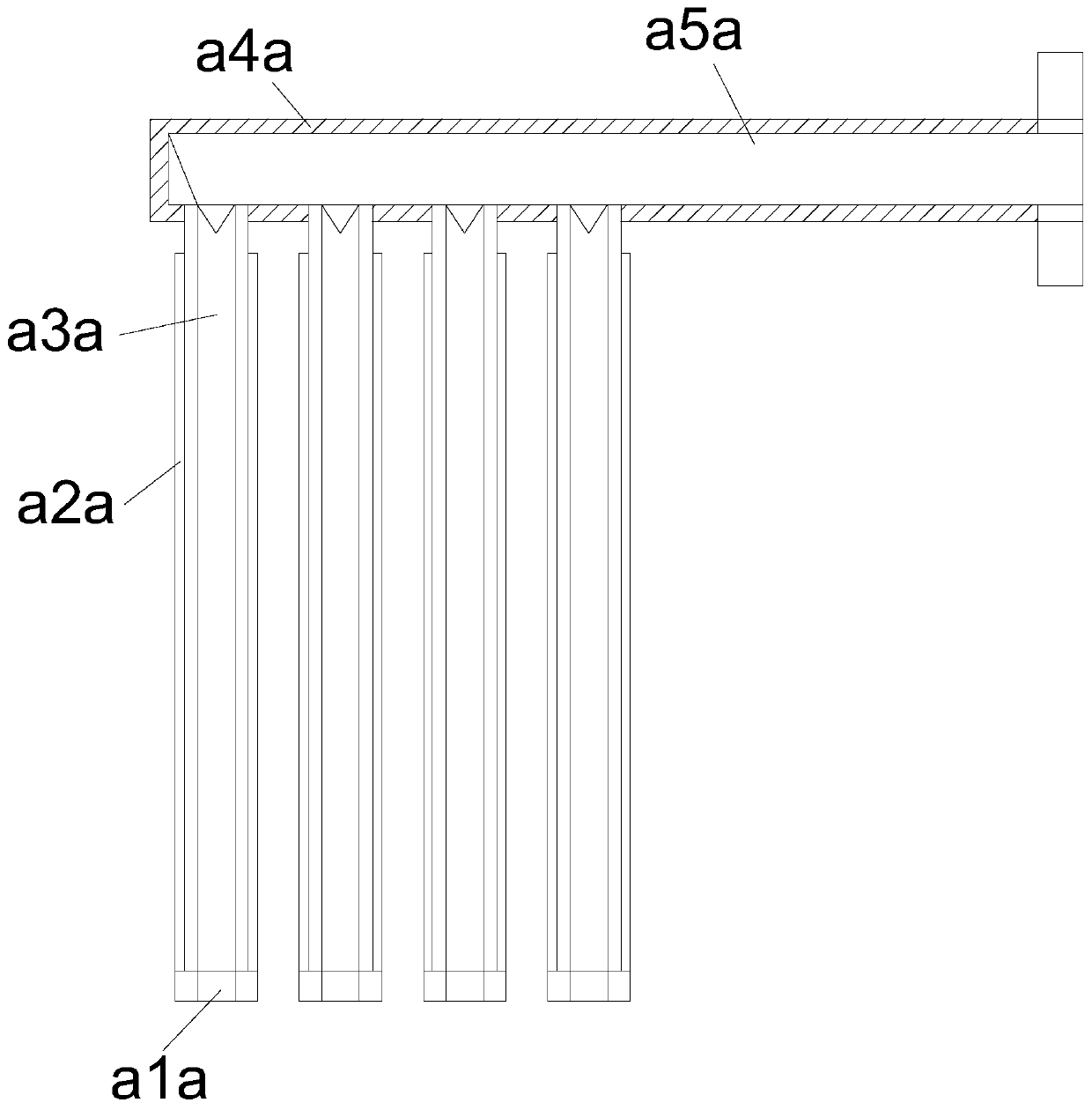

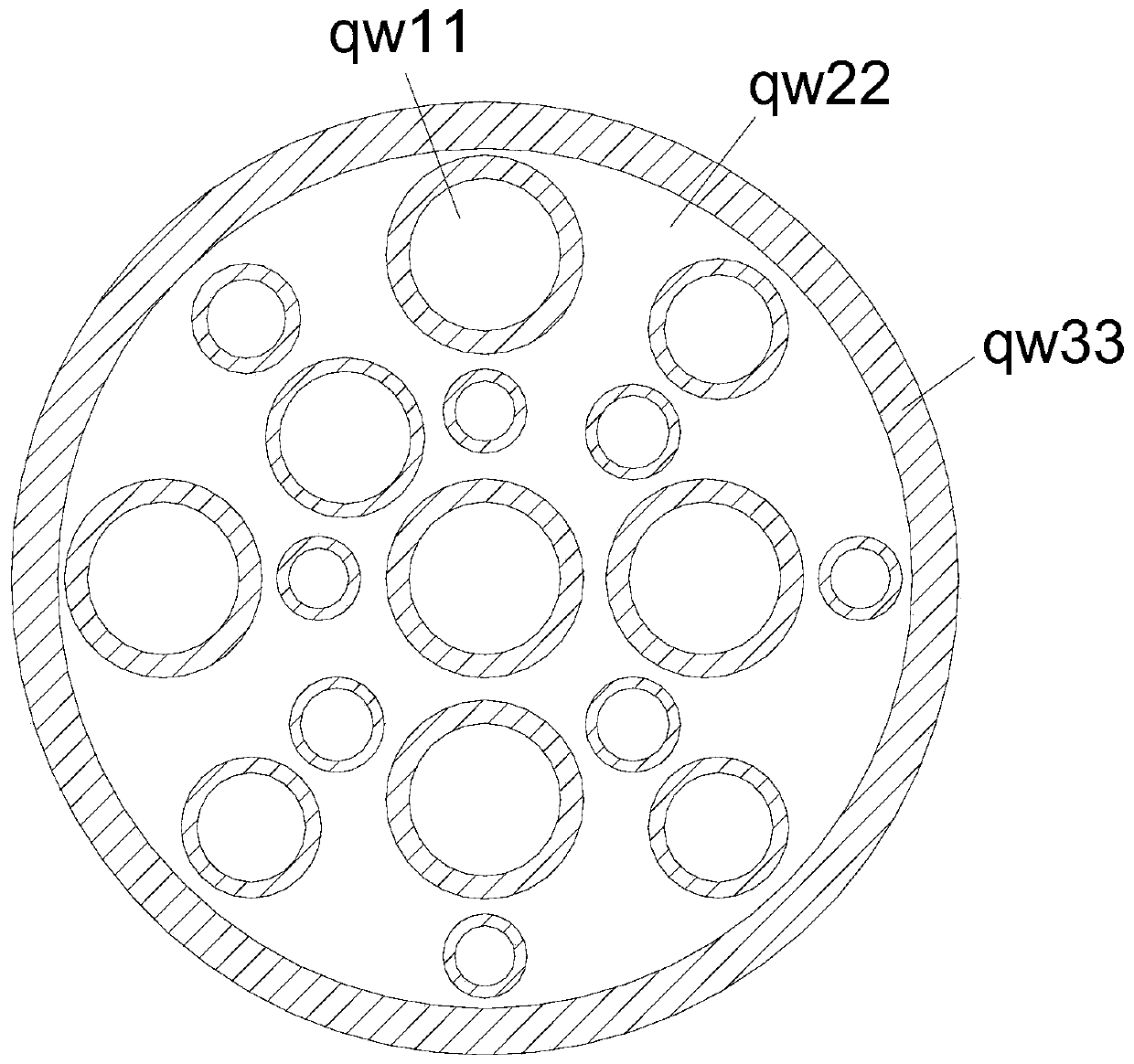

[0033] The ceramic filter port tt05 includes a filter port a1a, an outer suction ring a2a, a sponge ceramic body a3a, an outer pocket a4a, and a connecting pipe a5a. The filter port a1a is connected to the sponge ceramic body a3a, and the outer suction ring a2a fits On t...

Embodiment 2

[0040] as attached Figure 6 to attach Figure 7 Shown:

[0041] Wherein, the outer suction ring a2a includes an inclined vertex ss01, an outer soft edge ss02, an inner compartment ss03, and an inner channel ss04, the inclined vertex ss01 is connected with the outer soft edge ss02, and the inclined vertex ss01 is far away from the outer One end of the soft side ss02 is connected to the inner compartment ss03, the inner compartment ss03 is embedded with the inner channel ss04 and is located on the same axis, the inclined apex angle ss01 is evenly distributed in a circle, and the inner compartment ss03 It is a ring-shaped structure, the outer soft side ss02 plays a protective role for the internal parts, the inclined top angle ss01 assists the outer layer to fit the shape of the connected parts, and the inner partition ss03 separates the two sides.

[0042] Wherein, the inclined apex angle ss01 includes the inclined ball xx01, the abutment angle xx02, the extended welt xx03, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com