Waste gas treatment and purification equipment

A technology for purification equipment and waste gas treatment. It is applied in gas treatment, chemical instruments and methods, and dispersed particle filtration. It can solve problems such as troublesome installation and maintenance, save materials and improve treatment effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

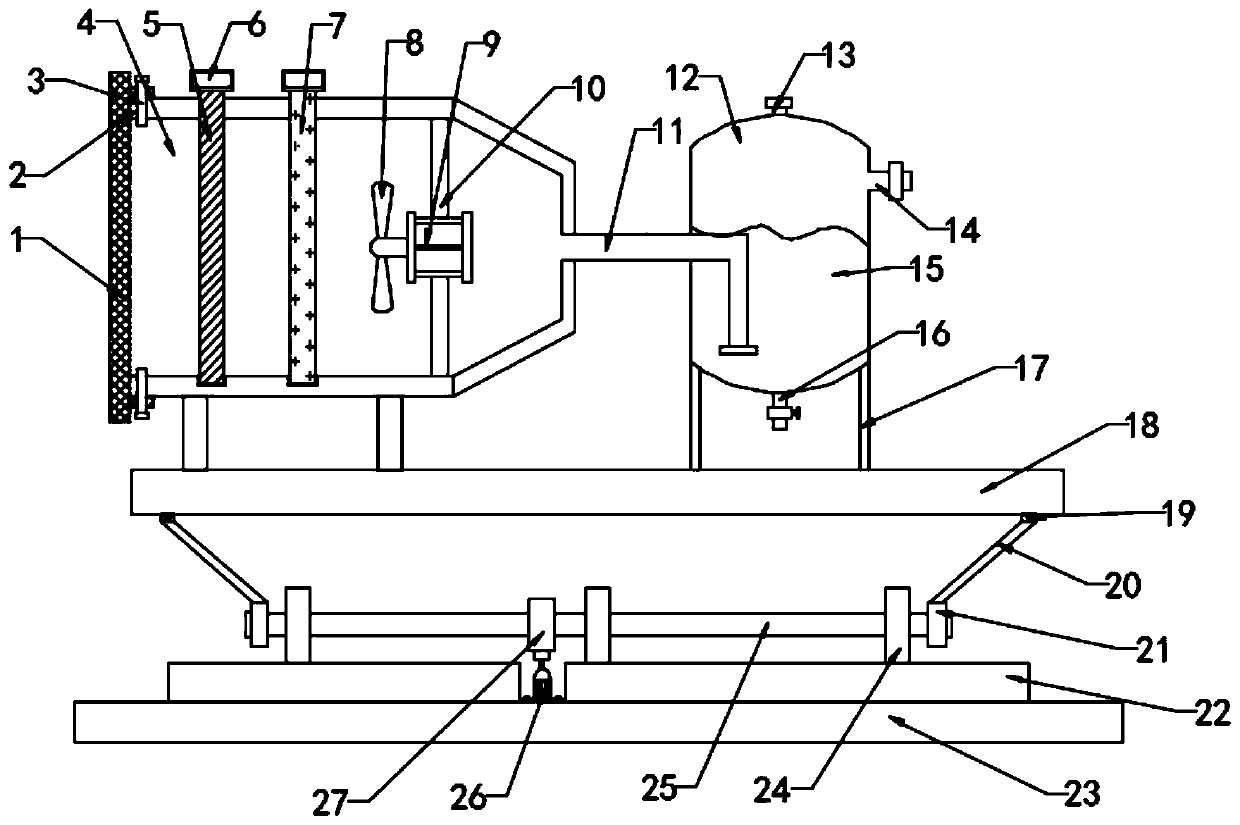

[0027] see figure 1 , in Embodiment 1 of the present invention, an exhaust gas treatment and purification equipment, which includes: a base 23, a backing plate 22 and a mounting seat 18, the backing plate 22 is arranged on the upper end of the base 23, and a lifting assembly is installed on the upper end of the backing plate 22. The upper end of the component is provided with a mounting seat 18, and the left and right sides of the lower end of the mounting seat 18 are provided with hinged blocks 19, and the mounting seat 18 is installed on the upper end of the lifting assembly through the hinged block 19;

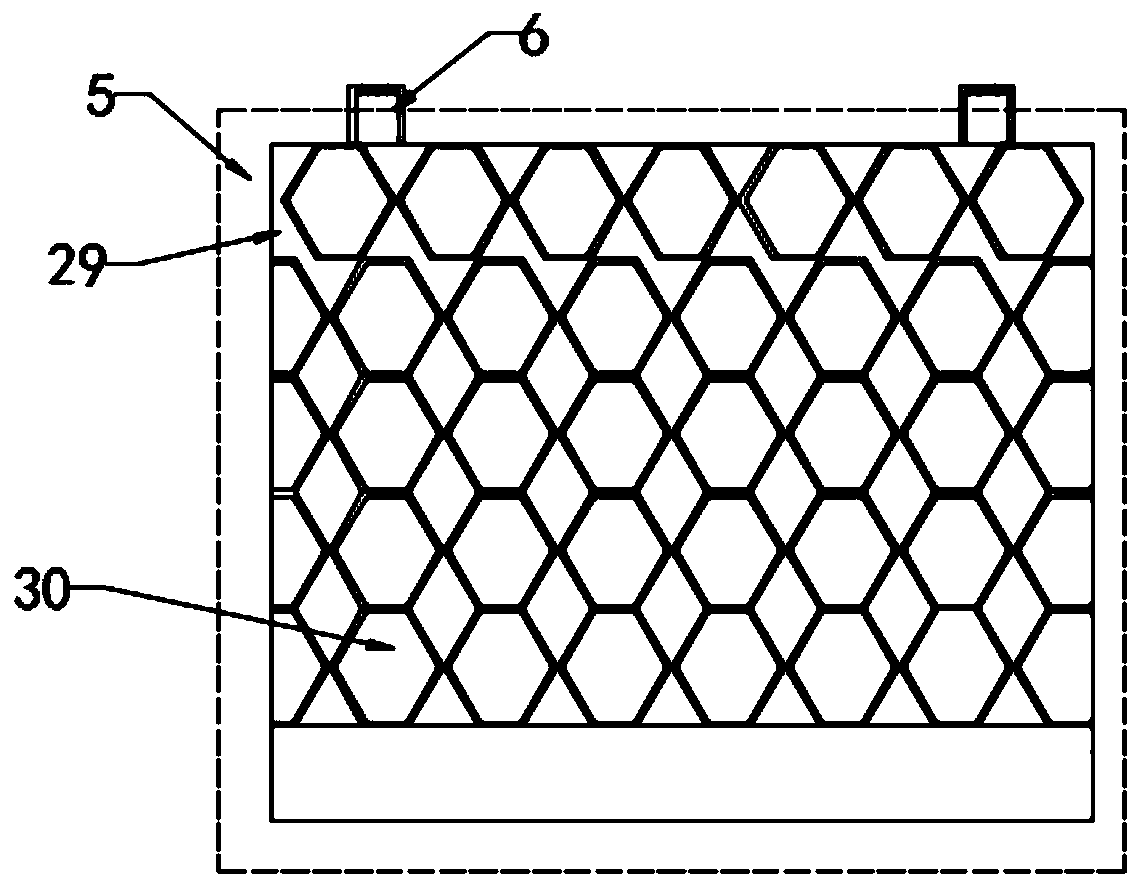

[0028] The left side of the upper end of the mounting seat 18 is provided with a purification box 2, and the purification box 2 is installed on the upper end of the mounting seat 18 through a support leg 17. The interior of the purification box 2 is a purification chamber 4, and the interior of the purification chamber 4 is provided with a purification assembly and an air su...

Embodiment 2

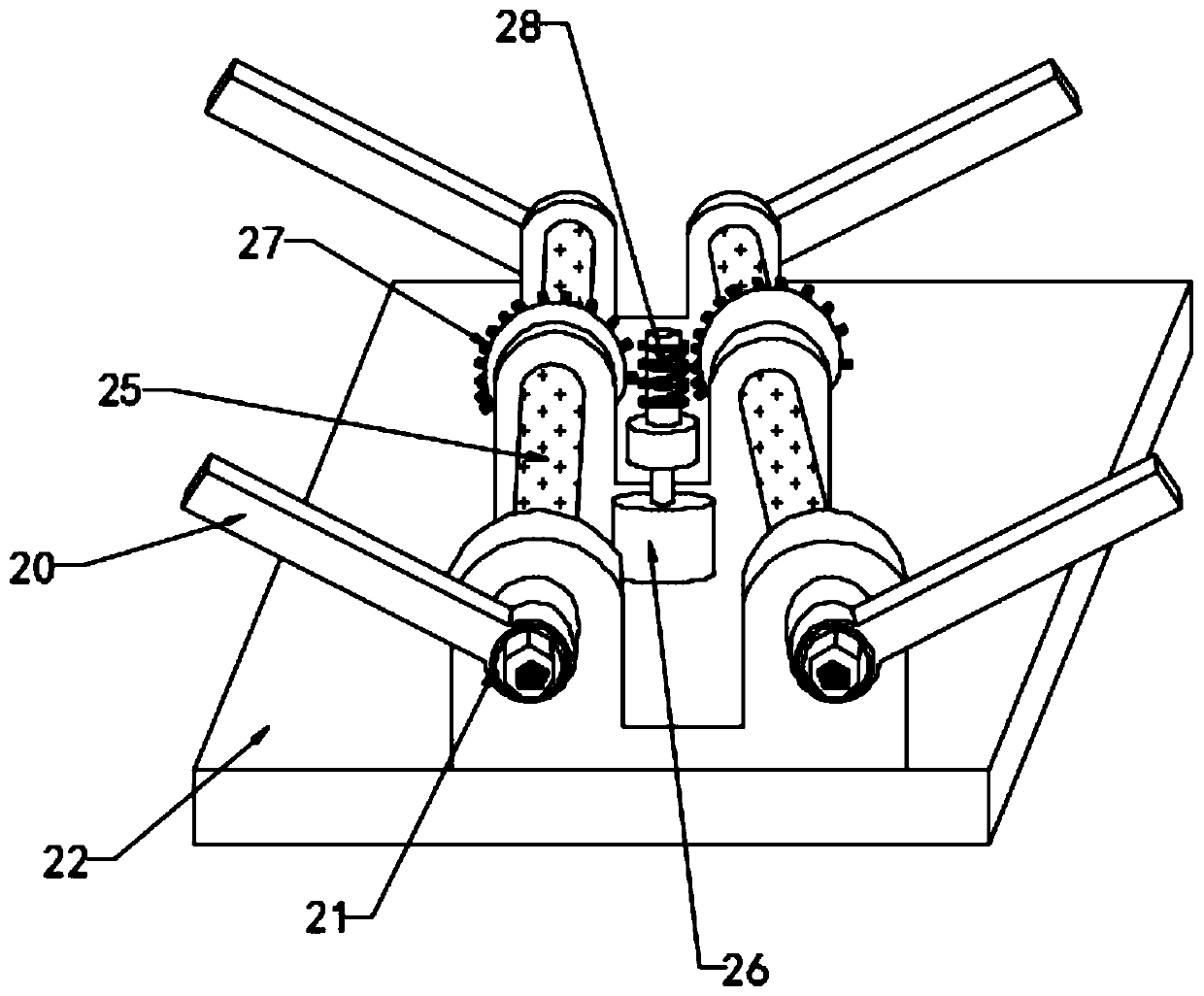

[0036] see figure 2 , further, the lifting assembly includes a rotating shaft 25, a worm 28 and a motor 26, the number of rotating shafts 25 is two, and one rotating shaft 25 passes through three limit blocks 24 at the same time, and the limit block 24 is installed on the upper end of the backing plate 22 , the rotating shaft 25 passes through the end portion of the limit block 24 on the left and right sides to be provided with a fixed ring 21, and a lifting frame 20 is installed and fixed on one side of the fixed ring 21, and the upper end of the lifting frame 20 is hingedly connected with the hinge block 19;

[0037] Specifically, a gear 27 is installed in the middle of the two rotating shafts 25, and a worm 28 is connected with a screw interference fit between the gears 27 on the two rotating shafts 25, and the lower end of the worm 28 is connected with the drive shaft of the motor 26, and the motor 26 is installed and fixed. on the backing plate 22;

[0038]Start the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com