Color-printing paperboard punching device

A punching device and cardboard technology, which is applied in paper/cardboard containers, packaging, papermaking, etc., can solve the problems of low processing efficiency, achieve better and more accurate creasing positions, avoid difficult output, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

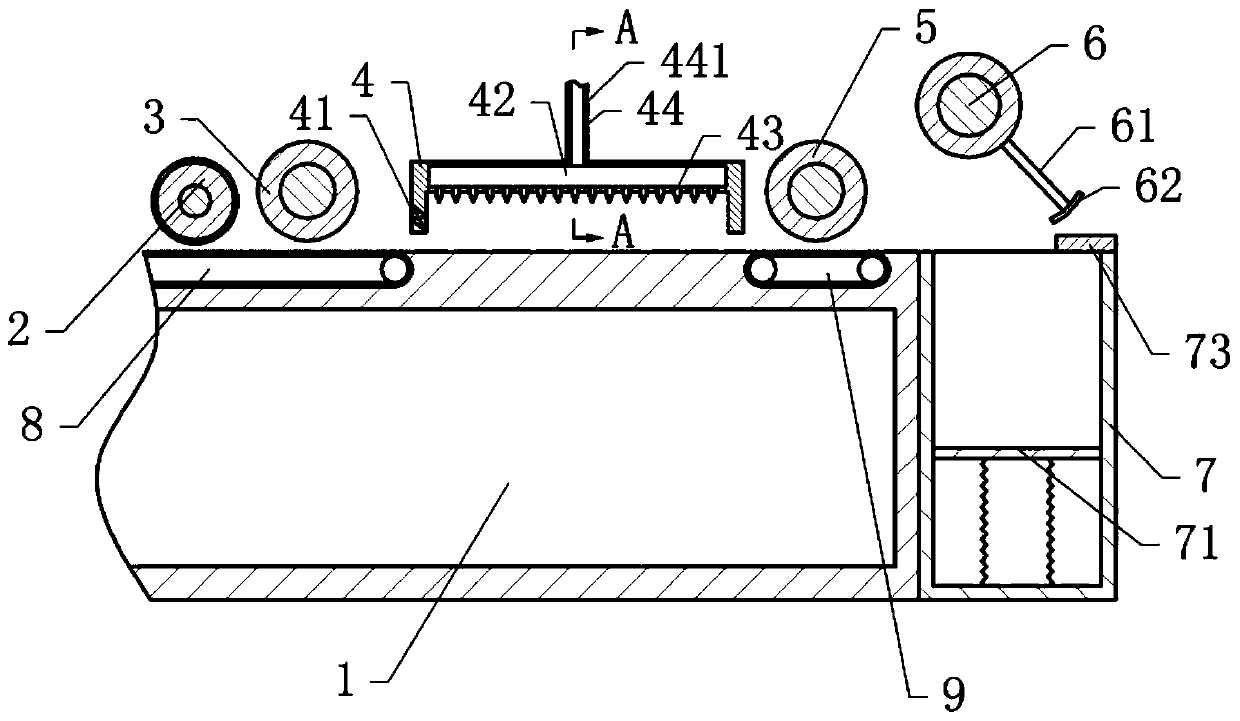

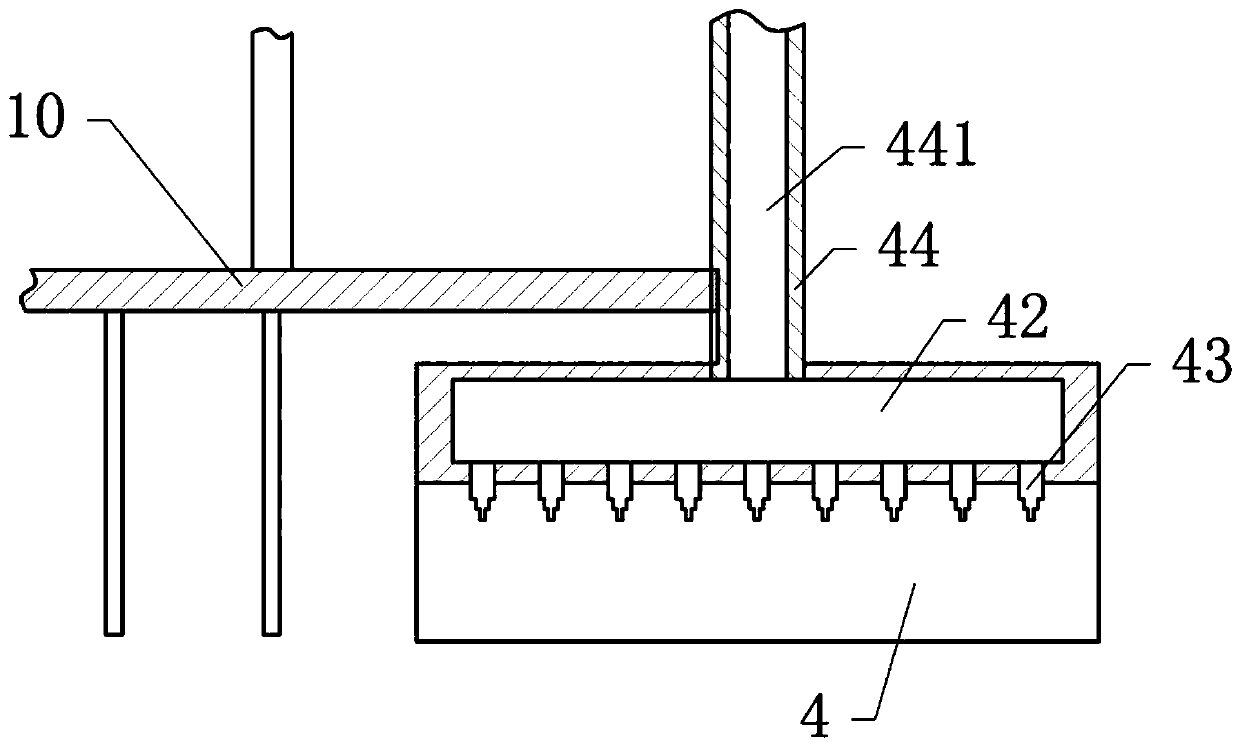

[0034] Color printing cardboard punching device, basically as attached figure 1 As shown, it includes a frame and a workbench 1 fixed on the frame. The frame is located above the workbench 1 and is sequentially provided with a crimping roller 2, an output roller 3, a frame body 4 and an input roller 5 from left to right. Line roll 2, output roll 3 and input roll 5 are all rotatably connected on the frame.

[0035] An output conveyor belt 8 is embedded in the workbench 1 below the output roller 3 , and the upper surface of the output conveyor belt 8 is flush with the upper surface of the workbench 1 . An input conveyor belt 9 is embedded below the input roller 5 in the workbench 1 , and the upper surface of the output conveyor belt 8 is flush with the upper surface of the workbench 1 . The output roller 3 is connected with the driving roller of the output conveyor belt 8 by a belt, the output roller 3 is connected with the crimping roller 2 by a belt, and the input roller 5 is...

Embodiment 2

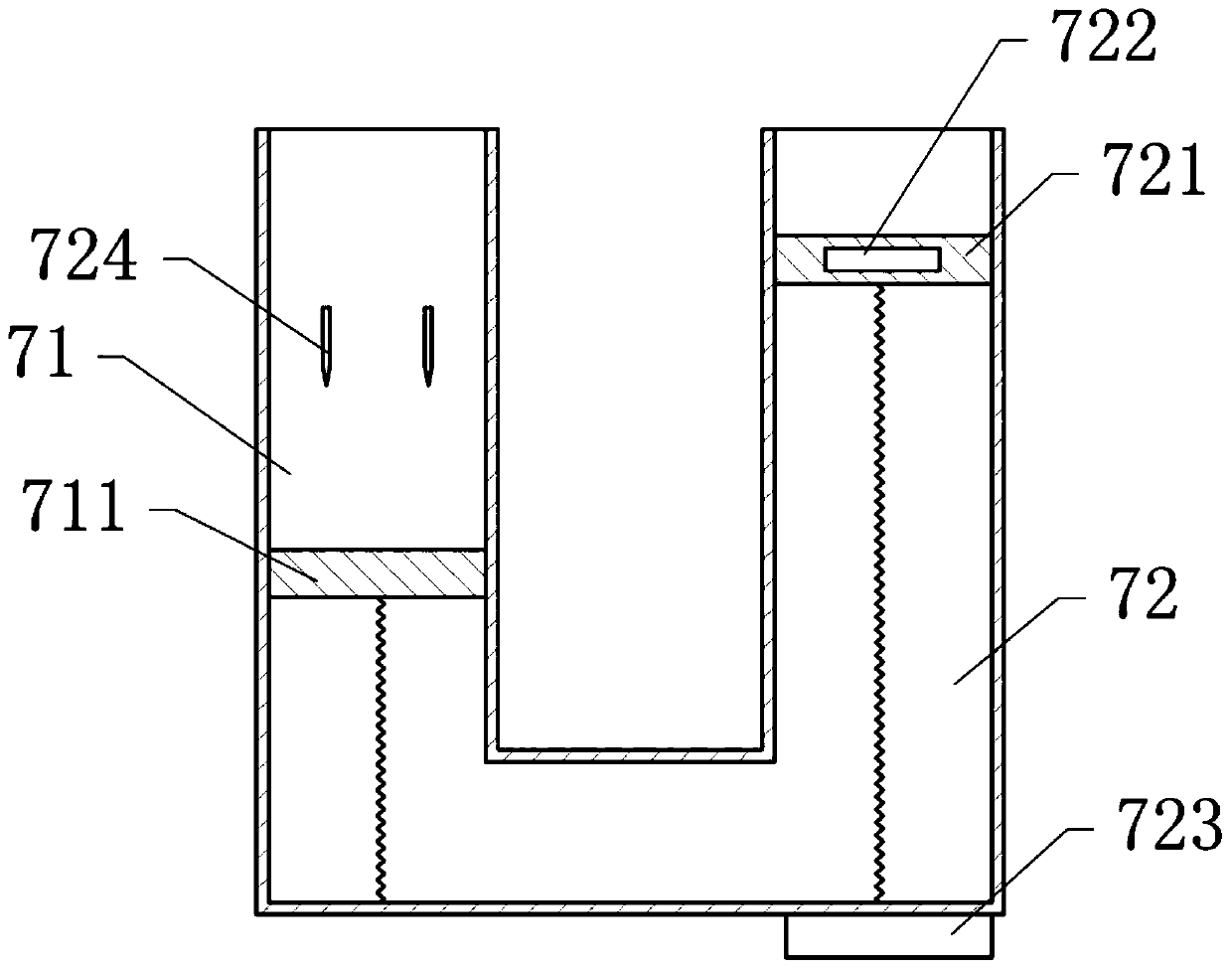

[0047] Embodiment 2 differs from Embodiment 1 only in that, as image 3 As shown, the storage box 7 is U-shaped, and the storage box 7 includes a vertical storage portion 71 , an adjustment portion 72 and a lateral portion. The storage portion 71 is located below the input roller 5 , and the storage platform 711 is located in the storage portion 71 . An adjustment platform 721 is vertically slidably connected to the adjustment part 72 , and a spring is provided between the adjustment platform 721 and the adjustment part 72 . An electromagnet 723 is provided at the bottom of the adjustment part 72, and an iron block 722 is provided on the adjustment table 721; a power supply is connected to the electromagnet 723, and conductive pins 724 are electrically connected to both ends of the power supply, and the conductive pins 724 are located on the upper part of the storage part 71 ; The storage box 7 is filled with electrolyte solution between the storage platform 711 and the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com