Concentric tool die

A tooling and mold technology, applied in the field of concentric tooling and molds, can solve the problems of affecting the effect of water treatment of electronic and electromagnetic equipment, failing to achieve the design purpose, affecting the effect of water treatment, etc., and achieves simple structure, convenient operation and convenient positioning. Effect

Pending Publication Date: 2020-04-28

张景尧

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the emitter is slightly out of concentricity in the auxiliary machine, a magnetic bias phenomenon will occur in the auxiliary machine, which will directly affect the effect of electronic and electromagnetic equipment on water treatment, failing to achieve the design purpose

In order to ensure that the emitter seat is concentric with the inner wall of the auxiliary machine when installing the emitter seat, a concentric tooling mold was invented to solve the problem of affecting the water treatment effect due to the different tooling.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

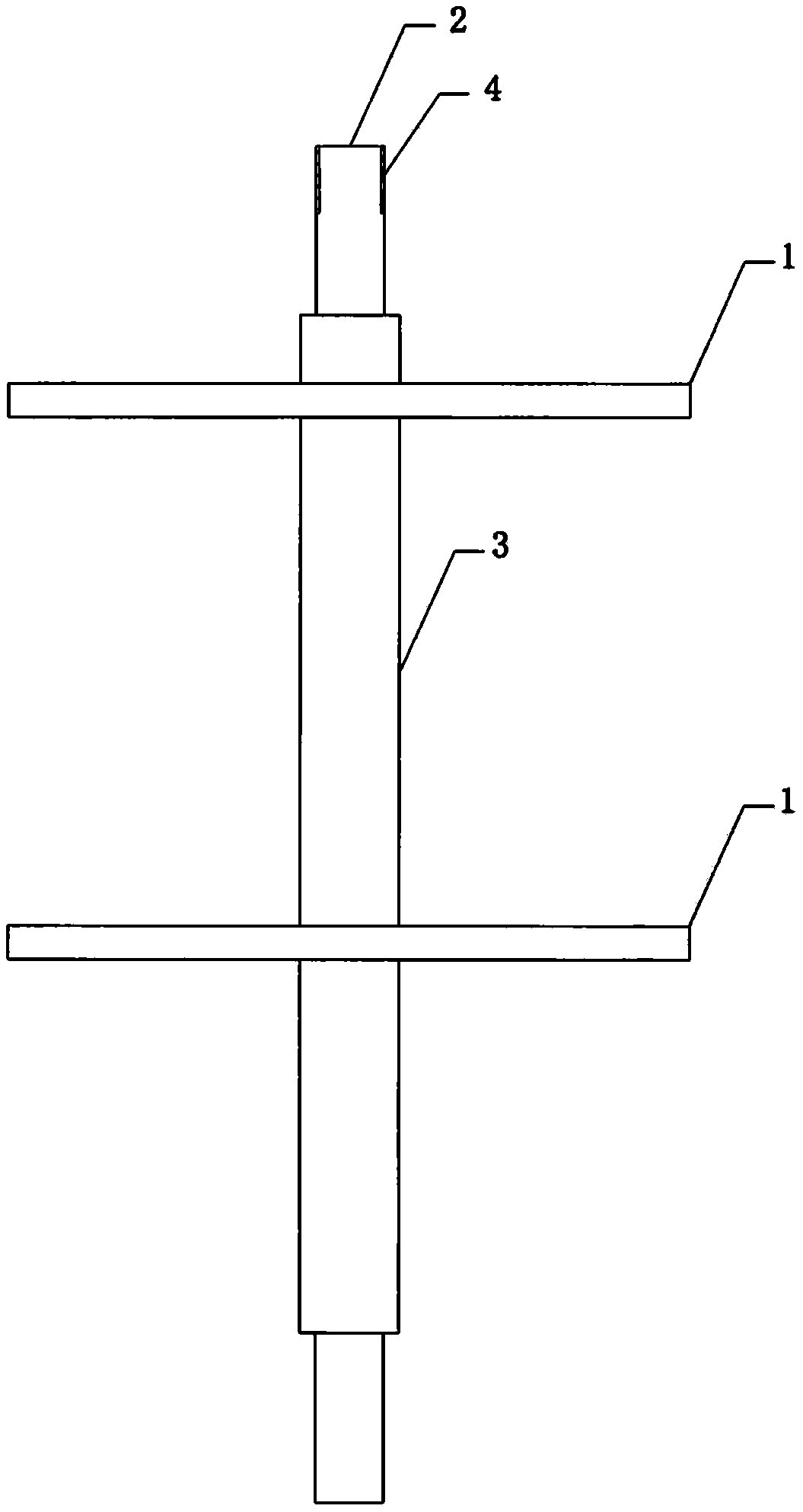

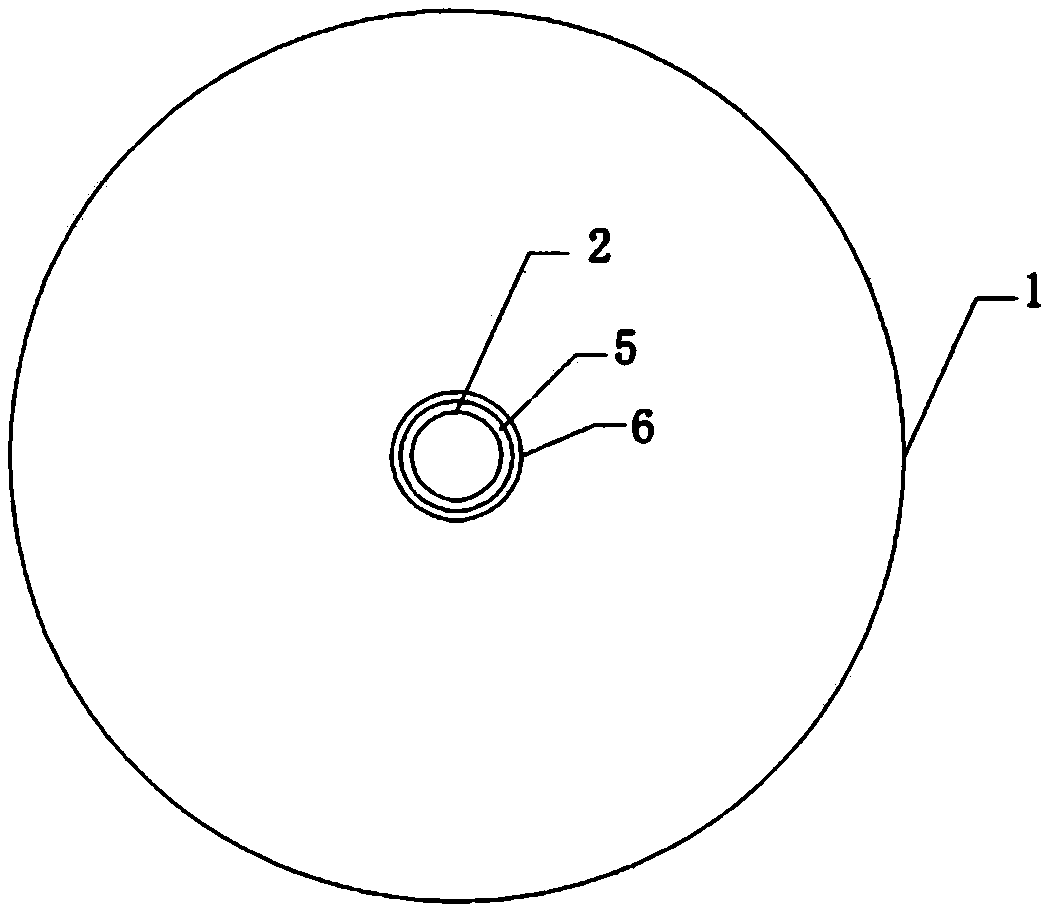

[0015] Such as Image 6 Shown: 7 is the auxiliary machine of water treatment equipment, when tooling 8 emitter seat, will Figure 5 insert Image 6 Inside the auxiliary machine of 7, and make 8 stuck in 5 and 6, the concentric positioning rod 2 passes through the concentric positioning tube 3 and make 4 on 2 and 9 on 8 dock, after the alignment is accurate, 8 and 7 are welded and fixed, In this way, the concentric precision of 8 and 7 is guaranteed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention discloses a concentric tool die which can be widely applied to electronic and electromagnetic water treatment equipment in manufacturing of an auxiliary machine and can ensure that an emitter is located in the middle of the auxiliary machine and the emitter is concentric with the inner wall of the auxiliary machine.

Description

[0001] Technology fields: [0002] The invention discloses a concentric tooling mold, which can be widely used in the manufacture of electronic and electromagnetic water treatment equipment to ensure that the emitter is in the middle of the auxiliary machine and ensure that the emitter is concentric with the inner wall of the auxiliary machine. Background technique: [0003] In the manufacture of electronic and electromagnetic water treatment equipment, due to the special properties of electronic and electromagnetic. If the emitter is slightly out of concentricity in the auxiliary machine, a magnetic bias phenomenon will occur in the auxiliary machine, which will directly affect the effect of electronic and electromagnetic equipment on water treatment, failing to achieve the design purpose. In order to ensure that the installation of the emitter seat is concentric with the inner wall of the auxiliary machine, a concentric tooling mold was invented, which solved the problem of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C02F1/00C02F1/48

CPCC02F1/00C02F1/48C02F1/484

Inventor 张景尧

Owner 张景尧

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap