Steelmaking waste hot water circulation treatment device

A recycling treatment, waste water hot water technology, applied in the direction of metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of harsh cooling water use environment, discounted cooling effect, mixed debris and oil pollution, etc. , to achieve the effect of good practical use and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

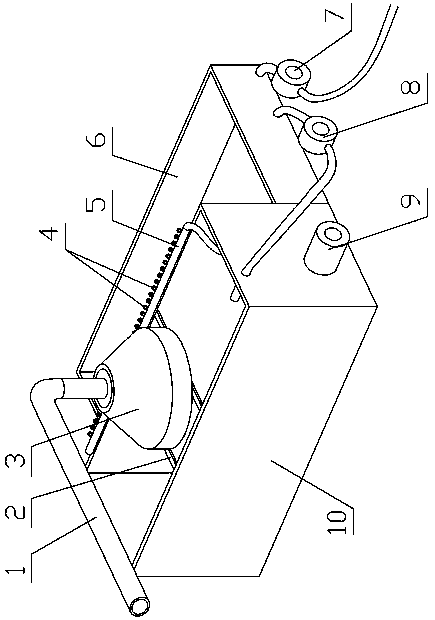

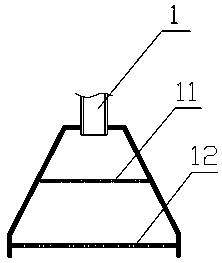

[0011] See attached figure 1 , figure 2 , The present invention is a steel-making waste hot water recycling treatment device with a first wastewater tank 10 and a second wastewater tank 6 arranged next to each other, wherein the height of the first wastewater tank is higher than the height of the second wastewater tank, and the first wastewater tank is above A truncated cone-shaped waste water filtering structure 3 is erected by the cross beam 2. The waste water filtering structure has a cavity inside, and two layers of filter screens are installed from top to bottom in the cavity. The upper filter screen 11 has a larger aperture than the lower filter screen. The aperture of the net 12, the lower filter screen directly communicates with the first waste water tank, and the top of the cavity is connected with a waste hot water inlet pipe 1; the first waste water tank is also equipped with a waste water inlet near the top edge of the second waste water tank. The root cloth water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com