Device for pulling and detaching plug at tail plate of tubular pile

A plug and tail plate technology, applied in workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of unfavorable plug cleaning and reuse, low work efficiency, high labor intensity, etc., and increase the difficulty of operation. , The effect of low work efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

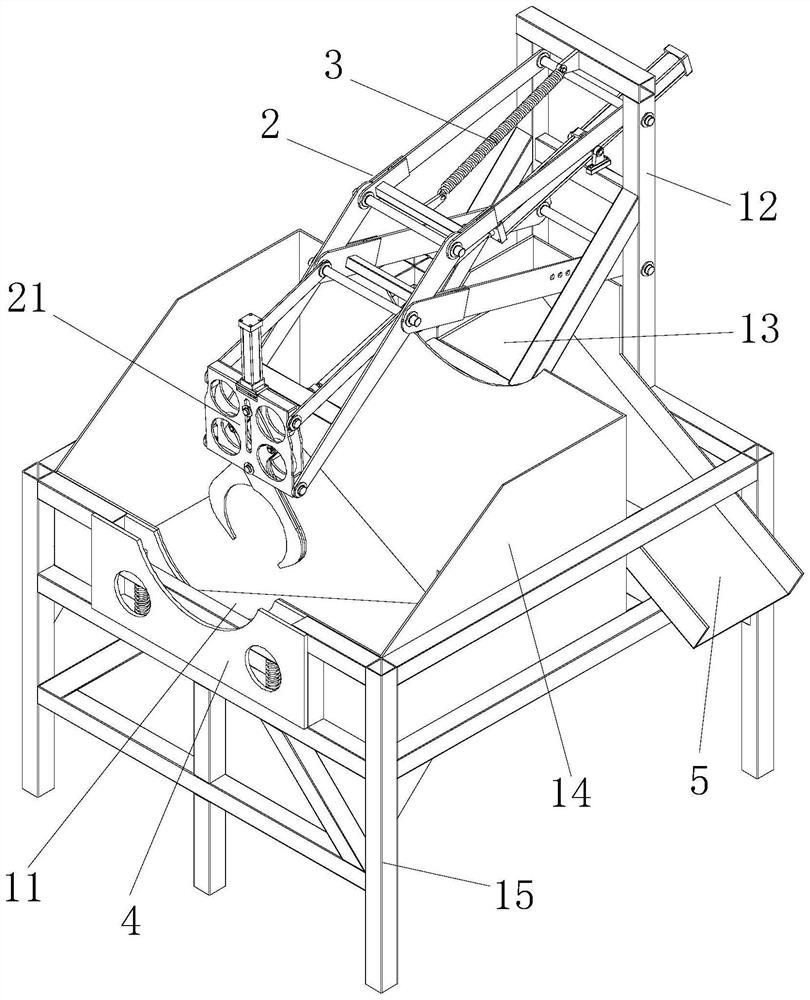

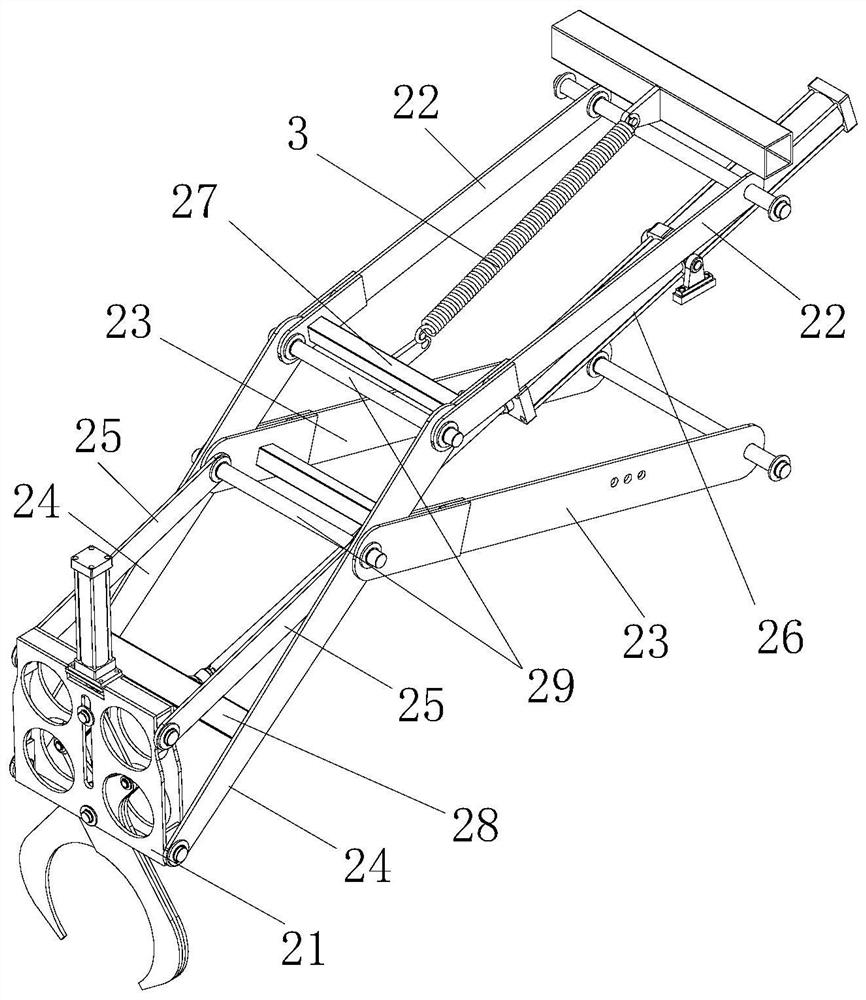

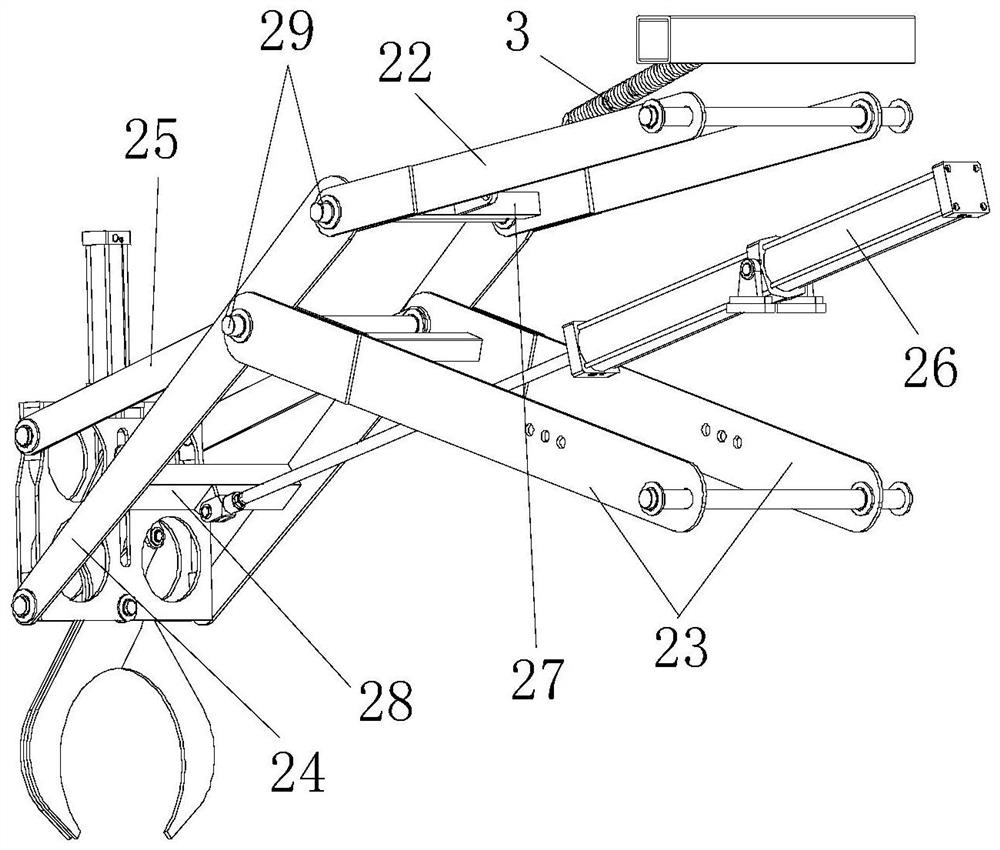

[0041] Such as Figure 1 to Figure 8 As shown, the present invention provides a pipe pile tail plate plug removal device, including a frame 1 and a flip telescopic manipulator 2, the left end of the frame 1 is provided with a bearing position 11 for carrying pipe piles, and the flip telescopic manipulator 2 is installed Component 12 is installed on the right end of frame 1, is provided with clamping assembly 21 on the flipping telescopic manipulator 2, and frame 1 is provided with collection position 13 below the flipping telescopic manipulator 2, and flipping telescopic manipulator 2 drives clamping assembly 21 toward The direction of the bearing position 11 is extended from bottom to top to clamp the plug and then retracted from top to bottom, which is used to pull out the plug and drive the plug to turn over and move to the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com