Waste Pavement Asphalt Recycling System

A technology for recycling and processing asphalt, applied in the fields of construction waste recycling, grain processing, plastic recycling, etc., can solve the problems of resource waste, random stacking or backfilling, environmental pollution of waste materials, etc., to improve the recycling effect and reduce road construction waste. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

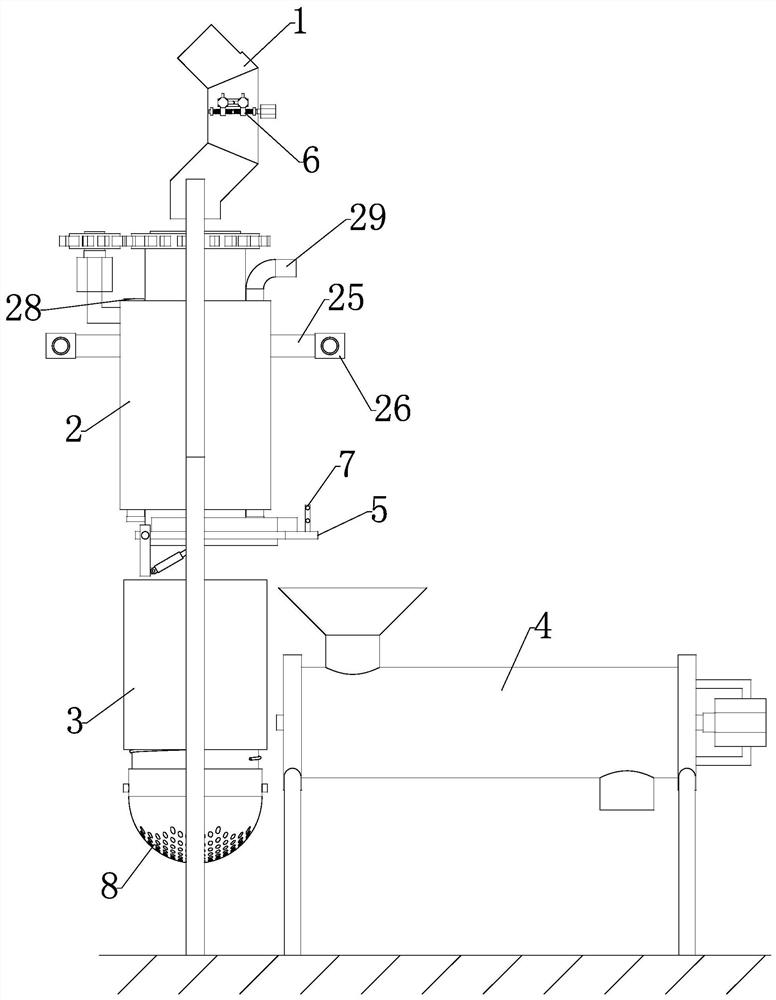

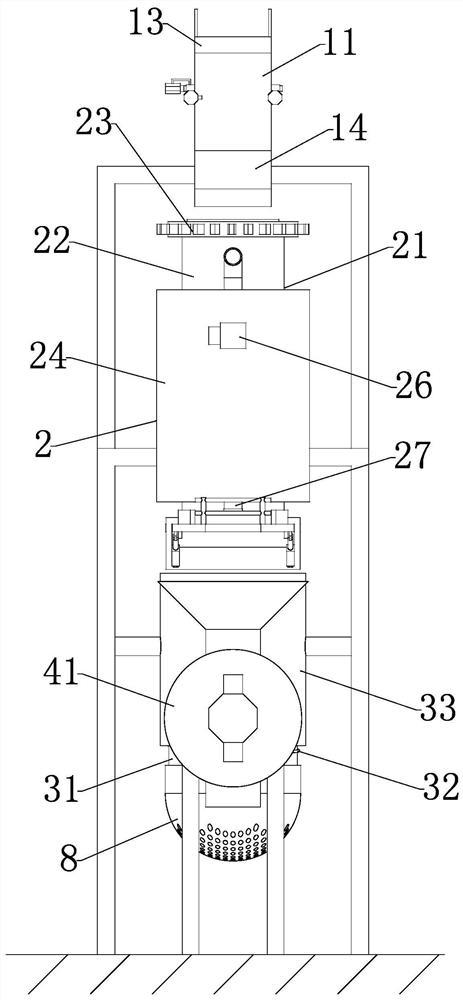

[0046] The waste pavement asphalt recycling system includes a feeding mechanism 1, and an asphalt separation device 2 is arranged downstream of the feeding mechanism 1, and the asphalt separation device 2 is used to receive the road surface waste materials from the feeding mechanism 1 and realize the cleaning of the road surface. For the preliminary separation of waste materials, an asphalt deep processing line 3 and a crushed stone recovery treatment line 4 are respectively installed in parallel downstream of the asphalt separation device 2. The asphalt deep processing line 3 is used to further process and recycle the separated asphalt to form a spare asphalt block , the crushed stone recycling line 4 is used to recover the separated crushed stones.

[0047] This system is mainly for the separation of asphalt and gravel and the subsequent recycling and classification of the waste pavement materials that have been initially crushed. The larger pieces of material are crushed ag...

Embodiment 2

[0062] Example 2: The difference from Example 1 is:

[0063] Preferably, the shredding assembly 12 includes two shredding rollers 1201 arranged in parallel and spaced apart in the shredding barrel 11 . There are a number of crushing knives 1202, and the crushing knives 1202 arranged opposite to each other on the two crushing rollers 1201 are alternately arranged, and a communicating crushing material is symmetrically arranged on the side walls of the crushing cylinder 11 at both ends of each crushing roller 1201. The inner and outer laterally elongated holes 1203 of the cylinder 11 are provided with a displacement adjusting assembly 6 on the outer sidewall of each laterally elongated hole 1203 outside the crushing cylinder 11 respectively, and the two ends of the crushing rollers 1201 pass through respectively The horizontally elongated holes 1203 at the corresponding positions pass through the crushing barrel 11 and are respectively movably matched with the displacement adjus...

Embodiment 3

[0067] Example 3: The difference from Example 2 is:

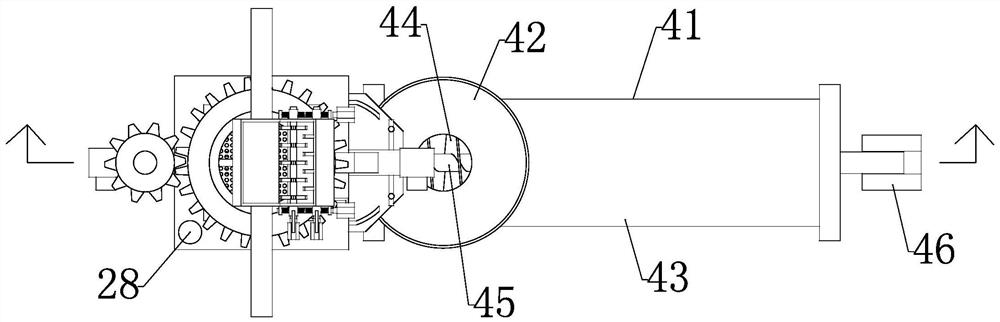

[0068] Preferably, the crushed stone stirring member 23 includes a steel cylinder 2301 that is fixedly inserted in the upper cavity of the central melting cavity 22, and a fixing ring 2302 is arranged in the central melting cavity 22 below the steel cylinder 2301 to be coaxial with it. Between the steel cylinder 2301 and the fixing ring 2302, a number of steel columns 2303 are evenly spaced along the circumferential direction. The upper and lower ends of the steel columns 2303 are welded to the bottom of the steel cylinder 2301 and the top of the fixing ring 2302 at the corresponding positions respectively. On the side wall of each steel column 2303 facing the center side of the central melting cavity 22, a number of feeding teeth 2304 are welded from top to bottom, and the upper end of the steel cylinder 2301 protrudes from the central melting cavity 22 and is welded firmly. Connect a hollow steel gear 2305 coaxially arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com