High chlorine silicon slurry modified ready-mixed concrete surface hardener and preparation method thereof

A technology for ready-mixed concrete and hardener, applied in the field of building materials, can solve the problems of unknown use effect of surface hardener, immature technical scheme, unclear specific compound of alcohol amine compound dosage, etc., so as to improve surface compactness and preparation method. Simple and easy to implement, reducing the effect of strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

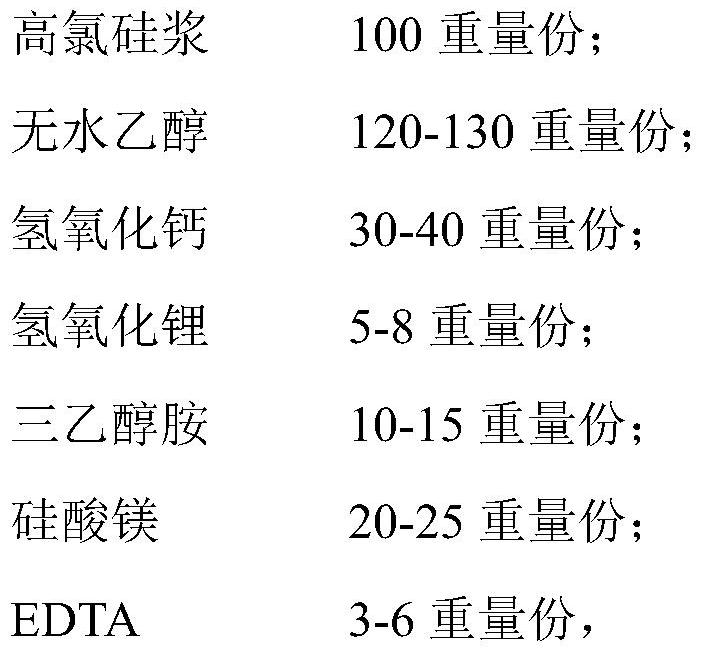

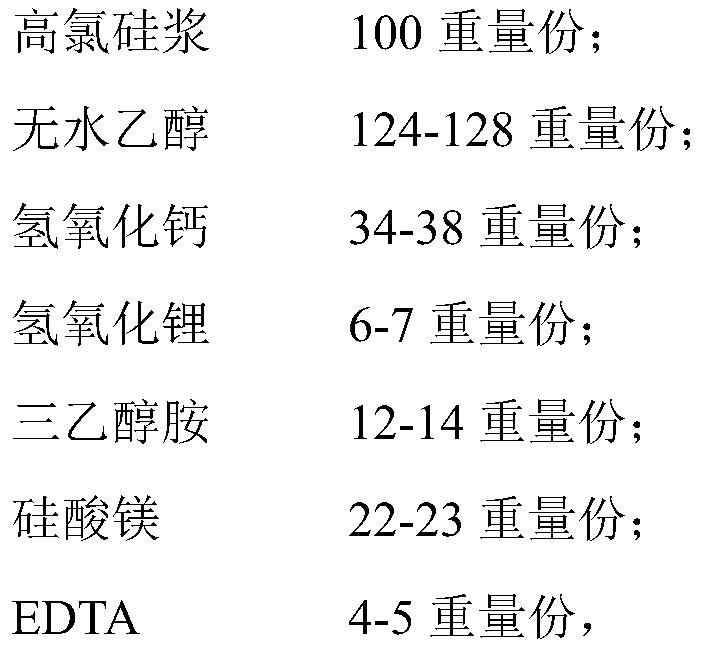

Method used

Image

Examples

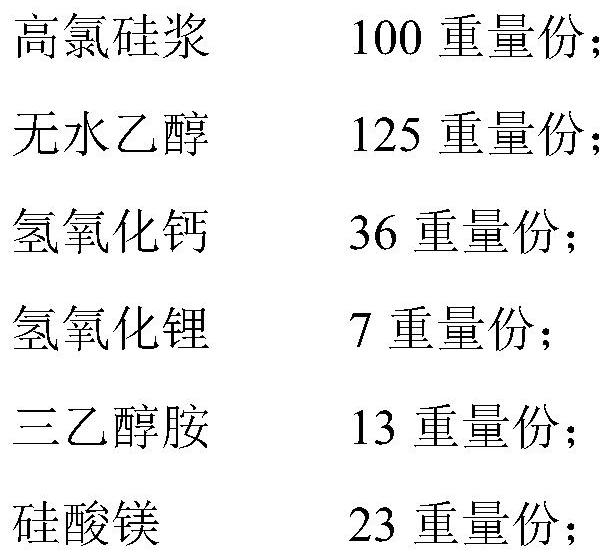

Embodiment 1

[0055] (1) Add 100g of high-chloride silicon slurry into 125g of absolute ethanol, and fully stir for 3 minutes;

[0056] (2) Slowly add 36g of calcium hydroxide and 7g of lithium hydroxide to the resultant of step (1), stir, and control the temperature below 65°C, and continue stirring for 6 minutes after the addition is completed;

[0057] (3) Add 13g of triethanolamine, 23g of magnesium silicate, 4g of EDTA, 19g of ethylene glycol and 2g of tributyl phosphate to the resultant of step (2), stir, and continue stirring after the addition is complete 5 minutes, thereby making the high chloride silicon slurry modified ready-mixed concrete surface hardener according to the present invention.

Embodiment 2

[0059] (1) Add 100g of high-chloride silicon slurry into 124g of absolute ethanol, and fully stir for 4 minutes;

[0060] (2) Slowly add 38g of calcium hydroxide and 6g of lithium hydroxide to the resultant of step (1), stir, and control the temperature below 65°C, and continue stirring for 7 minutes after the addition is completed;

[0061] (3) Add 14g of triethanolamine, 22g of magnesium silicate, 5g of EDTA, 18g of ethylene glycol and 3g of tributyl phosphate to the resultant of step (2), stir, and continue stirring after the addition is complete 6 minutes, thus making the high chloride silicon slurry modified ready-mixed concrete surface hardener according to the present invention.

Embodiment 3

[0063] (1) Add 100g of high-chloride silicon slurry into 128g of absolute ethanol, and fully stir for 4 minutes;

[0064] (2) Slowly add 34g of calcium hydroxide and 7g of lithium hydroxide to the resultant of step (1), stir, and control the temperature below 65°C, and continue stirring for 7 minutes after the addition is completed;

[0065] (3) Add 12g of triethanolamine, 23g of magnesium silicate, 4g of EDTA, 20g of ethylene glycol and 2g of tributyl phosphate to the resultant of step (2), stir, and continue stirring after the addition is complete 4 minutes, thus making the high chloride silicon slurry modified ready-mixed concrete surface hardener according to the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com