Strip steel surface appearance control method

A technology of surface morphology and control method, applied in the field of steel rolling, can solve problems such as poor surface compactness of strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

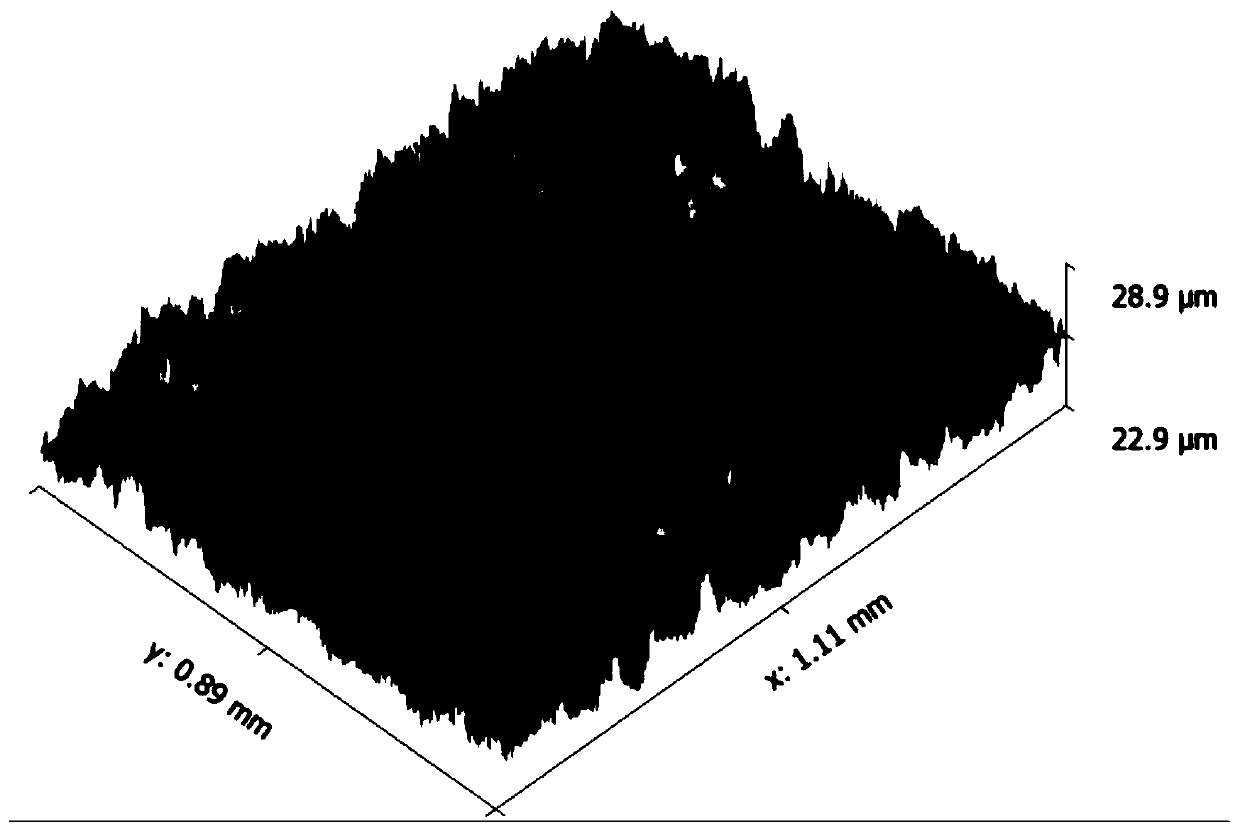

Embodiment 1

[0046] In this embodiment, a method for controlling the surface morphology of strip steel is applied to the wet leveling process of a double-frame temper machine, and the method includes:

[0047]According to preset conditions, the target strip steel is controlled to pass through the first work roll on the first frame of the double-frame tempering machine and the second frame of the double-frame tempering machine successively at a speed of 300m / min Continuous rolling of the second work roll; where,

[0048] The roughness of the first work roll is 2.0um, and the roughness of the second work roll is 1.2um;

[0049] The entry tension of the first work roll is less than the tension between the first work roll and the second work roll, the exit tension of the second work roll is less than the entry tension of the first work roll; and,

[0050] The entrance tension of the first work roll is 12kN, the tension between the first work roll and the second work roll is 15kN, and the exit...

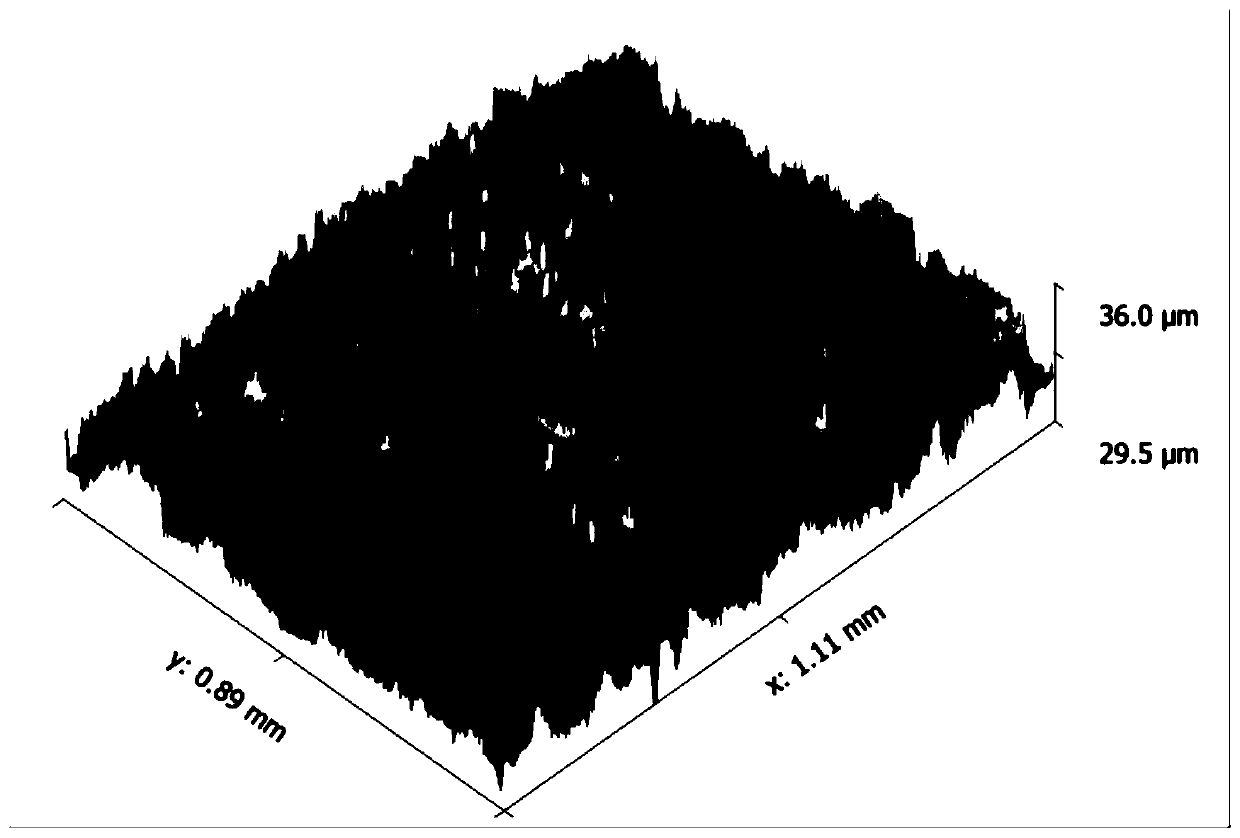

Embodiment 2

[0054] In this embodiment, a method for controlling the surface morphology of strip steel is applied to the wet leveling process of a double-frame temper machine, and the method includes:

[0055] According to preset conditions, the target strip is controlled to pass through the first work roll on the first frame of the double-frame tempering machine and the second frame of the double-frame tempering machine successively at a speed of 600m / min. Continuous rolling of the second work roll; where,

[0056] The roughness of the first work roll is 4.0um, and the roughness of the second work roll is 3.0um;

[0057] The entrance tension of the first work roll is 30kN, the tension between the first work roll and the second work roll is 40kN, and the exit tension of the second work roll is 25kN.

[0058] Further, in order to further improve the quality of the surface topography, the first elongation of the target steel strip after being rolled by the first stand machine is 0.7 of the ...

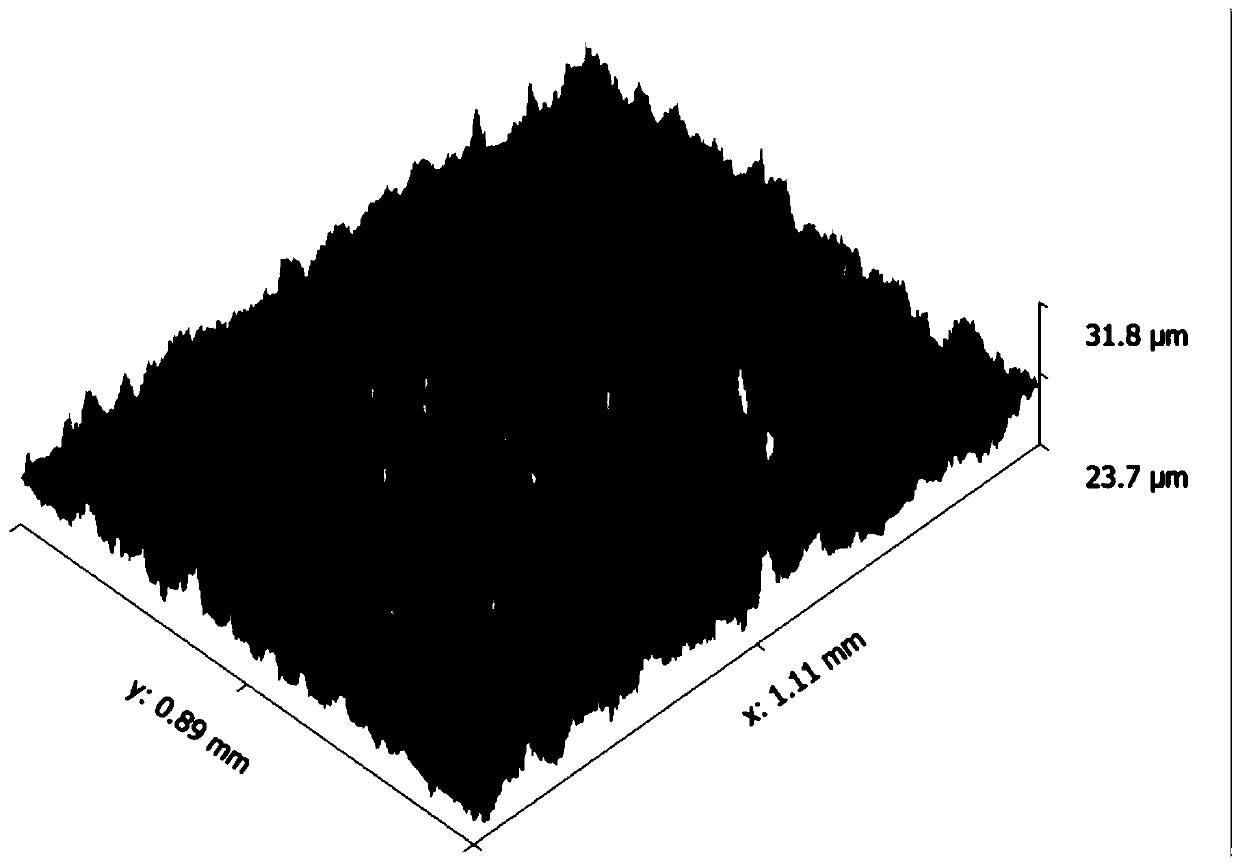

Embodiment 3

[0061] In this embodiment, a method for controlling the surface morphology of strip steel is applied to the wet-leveling process of a double-frame tempering machine. The method includes:

[0062] According to preset conditions, the target strip steel is controlled to pass through the first work roll on the first frame of the double-frame tempering machine and the second frame of the double-frame tempering machine successively at a speed of 500m / min. Continuous rolling of the second work roll; where,

[0063] The roughness of the first work roll is 3.5um, and the roughness of the second work roll is 1.2um;

[0064] The entrance tension of the first work roll is 27kN, the tension between the first work roll and the second work roll is 38kN, and the exit tension of the second work roll is 25kN.

[0065] Further, in order to further improve the quality of the surface topography, the first elongation of the target steel strip after being rolled by the first stand machine is 0.57 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com