Graphene aldehyde removing diatom board and preparation method thereof

A technology of aldehyde diatom board and graphene, which is applied in the field of graphene aldehyde removal diatom board and its preparation, can solve the problem of not decomposing formaldehyde, etc., and achieve improved surface compactness, excellent moisture absorption and release performance, and increased compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

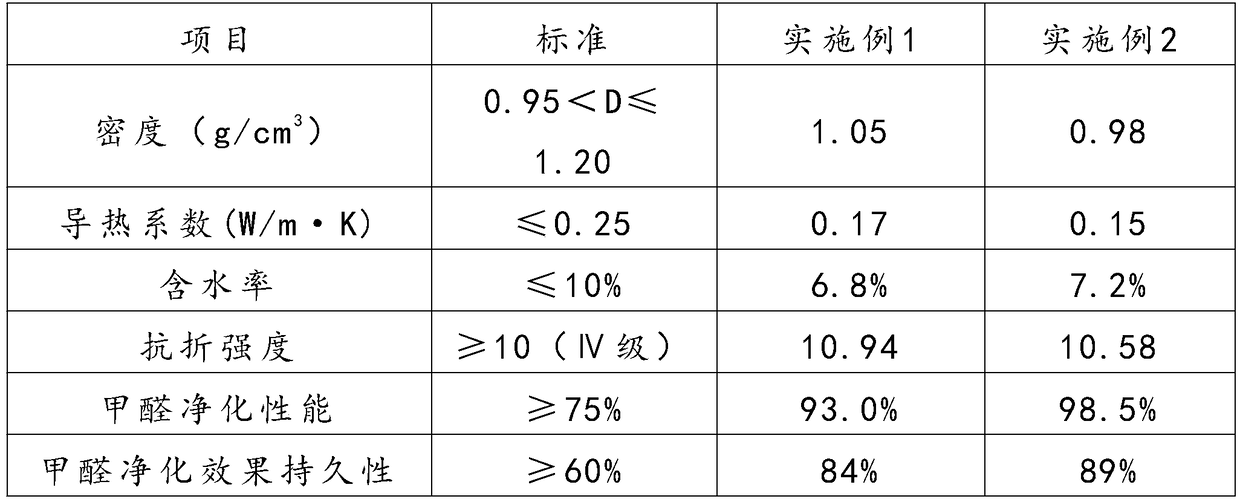

Embodiment 1

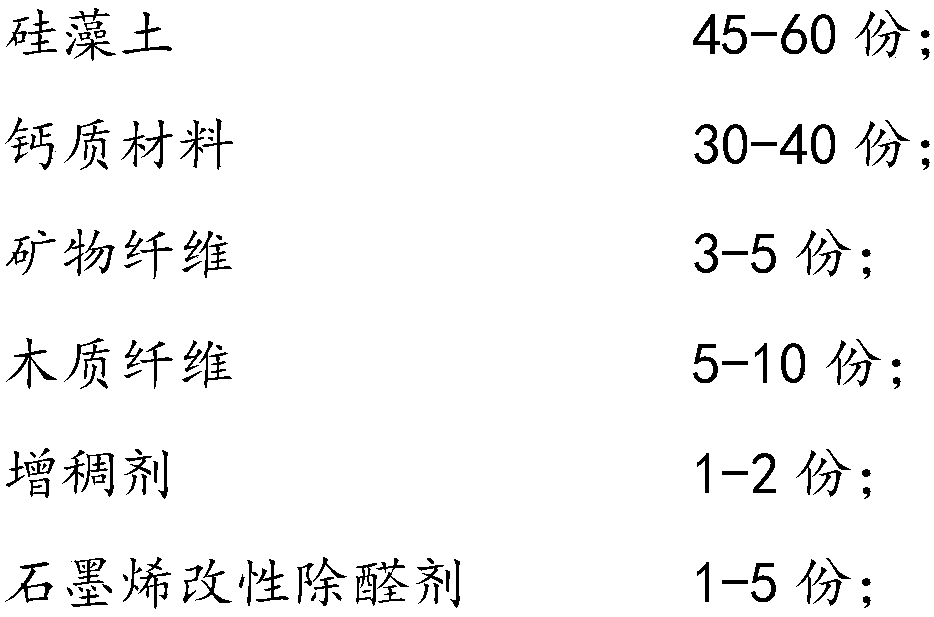

[0022] Embodiment 1: 60 parts of diatomite, 30 parts of calcareous material, 3 parts of mineral fiber, 4 parts of wood fiber, 1 part of thickener, 2 parts of graphene-modified formaldehyde removal agent, and 400 parts of water.

[0023] The preparation method is carried out according to the following steps:

[0024] (1) 60 parts by weight of diatomaceous earth, 30 parts by weight of calcium silicate with a particle size of 300 meshes, 3 parts by weight of calcium sulfate whiskers, 4 parts by weight of wood fibers, 1 part by weight of hydroxyethyl cellulose thickener and 2 parts by weight of 1 part of graphene-modified aldehyde-removing agent, add the water of 400 parts by weight and stir and fully mix, and stirring speed is 500r / min;

[0025] (2) Send the mixed material into the mixer at a constant speed again, after stirring evenly, flow to the release cloth through the outlet, and form a slab after extrusion and dehydration;

[0026] (3) Let the above-mentioned slab stand f...

Embodiment 2

[0027] Embodiment 2: 45 parts of diatomite, 38 parts of calcareous material, 4 parts of mineral fiber, 8 parts of wood fiber, 1 part of thickener, 4 parts of graphene-modified formaldehyde removal agent, 450 parts of water.

[0028] The preparation method is carried out according to the following steps:

[0029] (1) 45 parts by weight of diatomite, 38 parts by weight of a 1:1 mixture of calcium silicate and calcium hydroxide with a particle size of 500 mesh, 3 parts by weight of attapulgite clay, 4 parts by weight of wood fiber, and 1 part by weight of methyl Hydroxyethyl cellulose thickener and 4 parts by weight of graphene-modified aldehyde-removing agent, add the water of 450 parts by weight and stir fully mix, and stirring speed is 400r / min;

[0030] (2) Send the mixed material into the mixer at a constant speed again, after stirring evenly, flow to the release cloth through the outlet, and form a slab after extrusion and dehydration;

[0031] (3) Let the above-mentioned ...

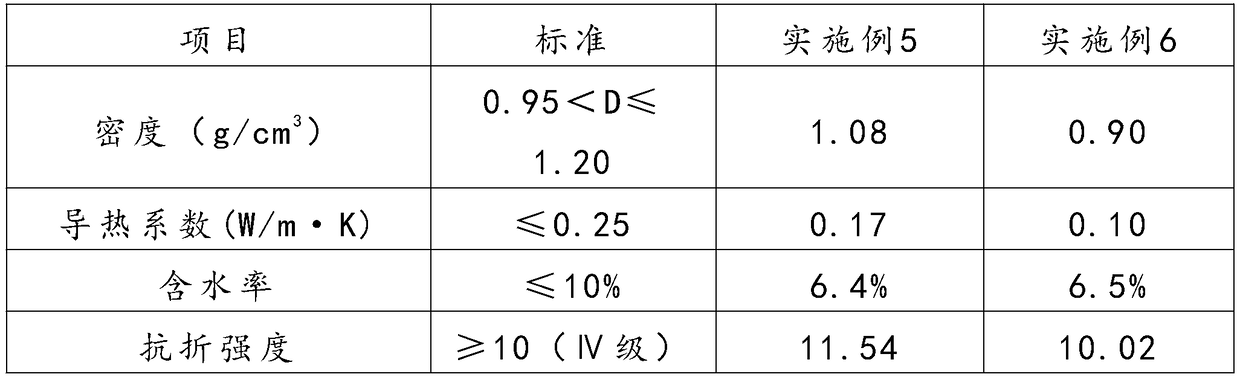

Embodiment 3

[0036] Example 3: At present, ordinary diatom board mainly consists of 60-75 parts by weight of diatomite, 22-30 parts by weight of calcium material, 1.5-6 parts by weight of wood fiber and 2.5-7 parts by weight of hard fiber. The materials are dehydrated by mixing suppressed. Density 1.0g / cm 3 , thermal conductivity 0.17W / m·K, moisture content 7.2%, no long-term decomposition of formaldehyde function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com