Composite absorbing layer pyroelectric infrared detector

A pyroelectric infrared and composite absorbing layer technology, which is applied in thermoelectric devices, electric radiation detectors, thermoelectric devices with thermal changes in dielectric constant, etc., can solve the problems of complex manufacturing process and high manufacturing cost, and achieve dense coating layer, High absorption coefficient, effect of improving absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

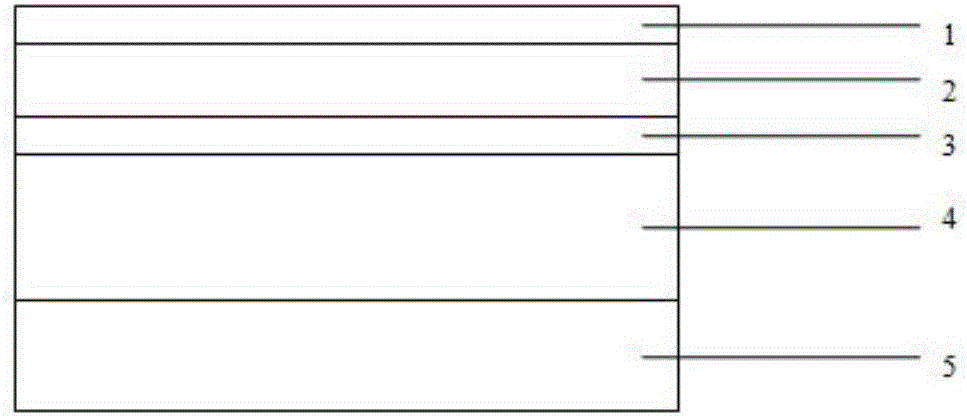

[0024] A composite absorbing layer pyroelectric infrared detector, the absorbing layer in the infrared sensor unit is a composite layer structure, including: titanium metal layer 1, dielectric layer 2, nickel-chromium alloy layer 3, lithium tantalate crystal layer 4 and reflective layer 5;

[0025] In the present invention, the sensitive element of the pyroelectric infrared detector is firstly prepared. In this embodiment, the lithium tantalate crystal is selected, and the lithium tantalate crystal material is subjected to grinding, polishing, chemical corrosion and / or cleaning, etc., to obtain a lithium tantalate crystal substrate ;

[0026] The material of the reflective layer 5 can be nickel-chromium alloy, which is deposited on the bottom surface of the lithium tantalate crystal layer 4 by radio frequency magnetron sputtering; the nickel-chromium alloy layer 3 is deposited on the lithium tantalate crystal layer by radio frequency magnetron sputtering 4; the material of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com