Construction Method of Foundation Pit with Turnable Steel Support

A construction method and steel support technology, which can be applied in basic structure engineering, excavation, construction, etc., can solve the problems of low construction precision of round steel support, difficulty in controlling foundation pit deformation, difficulty in maintaining pre-stressing, etc., to overcome site transportation Inconvenient, long service life, high installation accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

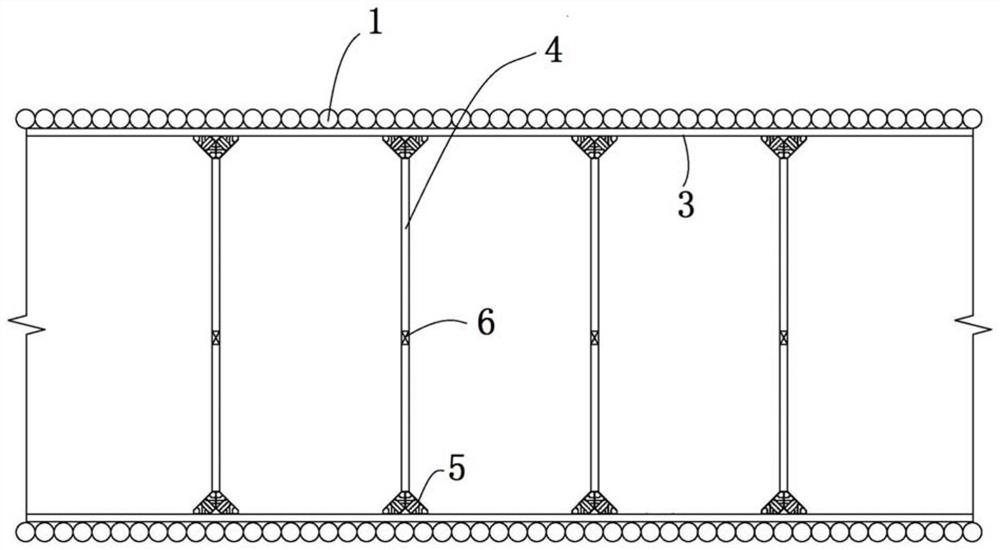

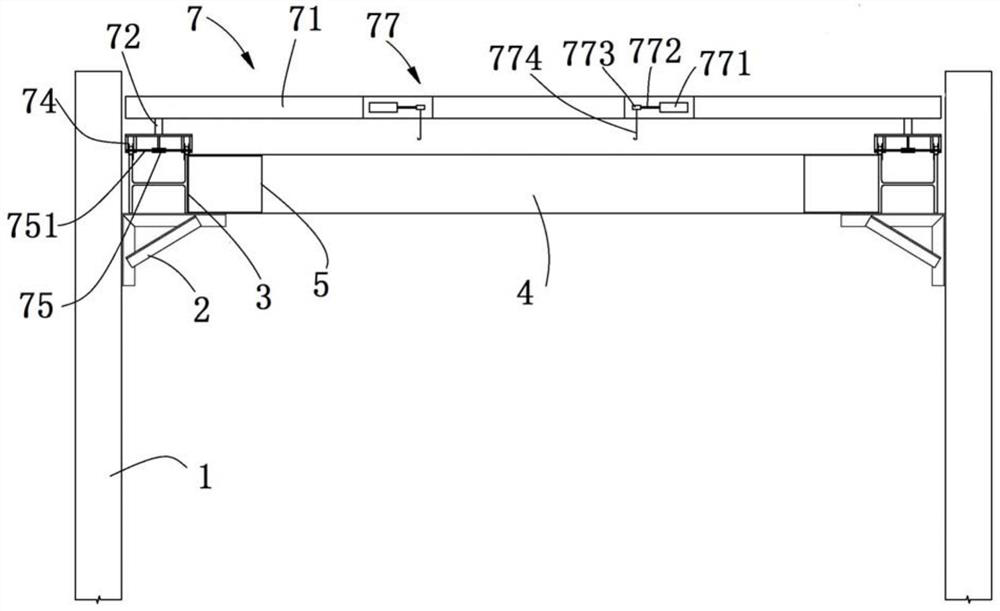

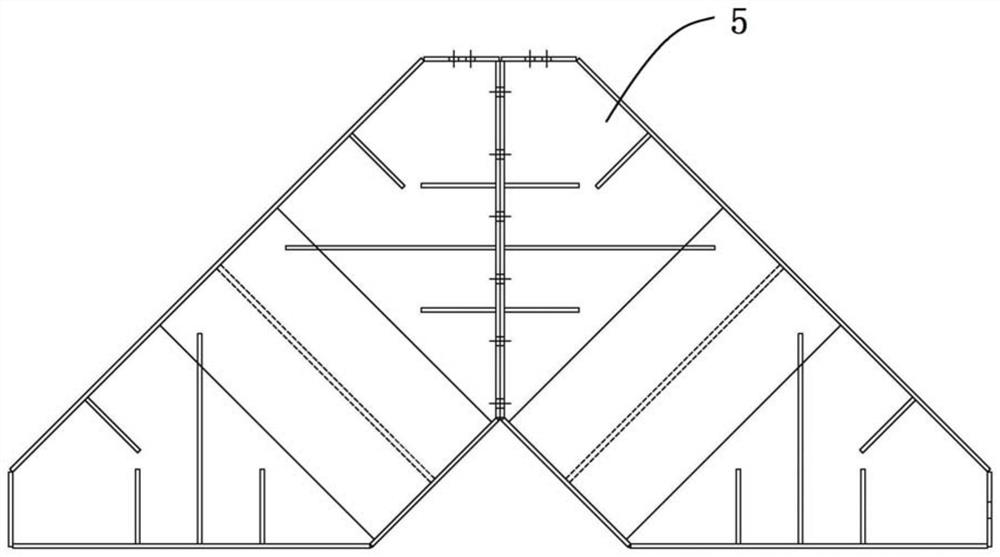

[0036] see figure 1 , figure 2 As shown, the present invention provides a kind of foundation pit construction method that the steel support can be turned over, comprising the following steps:

[0037] The foundation pit construction area is divided into multiple sections along the length direction of the foundation pit, and the construction of the vertical support structure 1, the installation of the purlin 3, the installation of the steel support 4 and the excavation of the foundation pit are carried out section by section. dig, where:

[0038] The construction of the vertical support structure 1 includes embedding two rows of vertical support structures 1 on both sides of the foundation pit construction area along the length direction of the foundation pit, and the top of the vertical support structure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com