Rotor pump convenient to overhaul and using method thereof

A rotor pump and rotor technology, which is applied in the field of rotor pumps that are easy to maintain, can solve the problems of inconvenient disassembly of the rotor and the main shaft, achieve good practical value, realize the sealing effect, and ensure the effect of normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

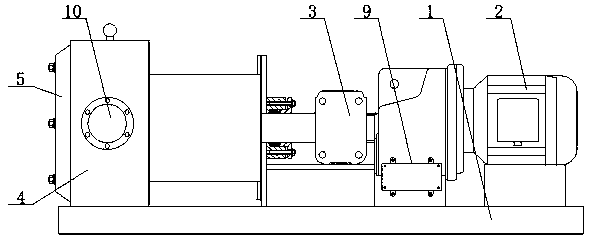

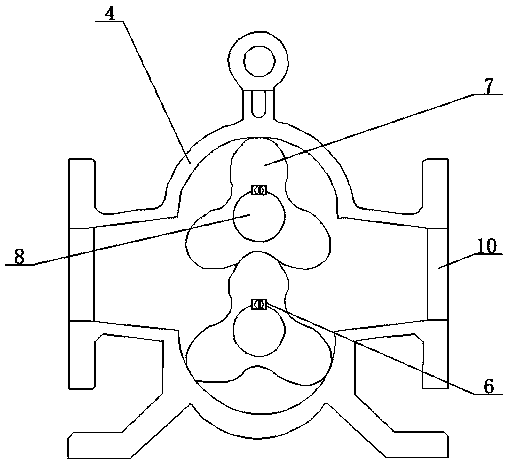

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , the present invention provides a technical solution:

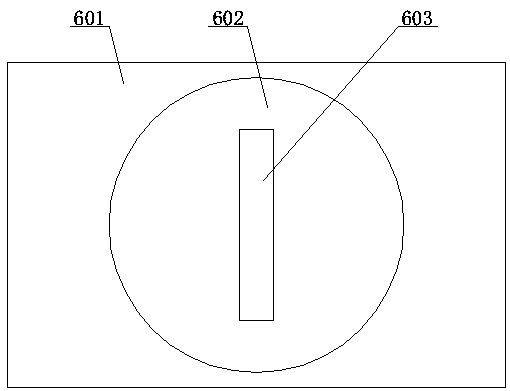

[0032] A rotor pump for easy maintenance and its use method, comprising a base 1 and a motor 2, the upper end of the base 1 is fixedly connected with a motor 2 and a pump casing 4 distributed left and right, the end of the main shaft of the motor 2 is fixedly connected with a shaft coupling 3, the coupling The other side of the shaft device 3 is fixedly connected with the pump casing 4, the front and rear sides of the pump casing 4 are provided with through holes 10, the left end of the pump casing 4 is fixedly connected with the casing 5, and the inner side of the pump casing 4 is rotatably connected with the main shaft 8 distributed up and down , the outside of the main shaft 8 is provided with a key mechanism 6, the key mechanism 6 includes a key body 601 and a rotating ring 602, the left end surface of the key body 601 ...

Embodiment 2

[0040] In embodiment 2, the same parts as embodiment 1 will not be repeated. The difference is that when the shell 5 is disassembled, cracks are found on the surface of the rotor 7 and the main shaft 8, and it needs to be repaired at this time, because the key body Under the effect of 601, it is not easy to disassemble. At this time, insert a screwdriver into the limiting groove 603, and then rotate the rotating ring 602. The rotating ring 602 drives the threaded rod 604 to rotate, and the threaded rod 604 drives the limiting plate 605 to rotate, so that the rotating ring 602 and the The key body 601 is separated, and the set limit plate 605 prevents the threaded rod 604 from breaking away from the key body 601 during use. At this time, by using the rotating ring 602 and the threaded rod 604 as a point of leverage, it is easy to remove the key body 601 from The rotor 7 is separated from the main shaft 8, which is very convenient for the replacement and maintenance of the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com