Air conditioning system

A technology of air conditioning system and cooling section, applied in the field of air conditioning, can solve the problems of wasting cooling capacity, increasing the pressure difference between condenser and evaporator, affecting the reliability and performance of the unit, and achieving the effect of improving reliability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

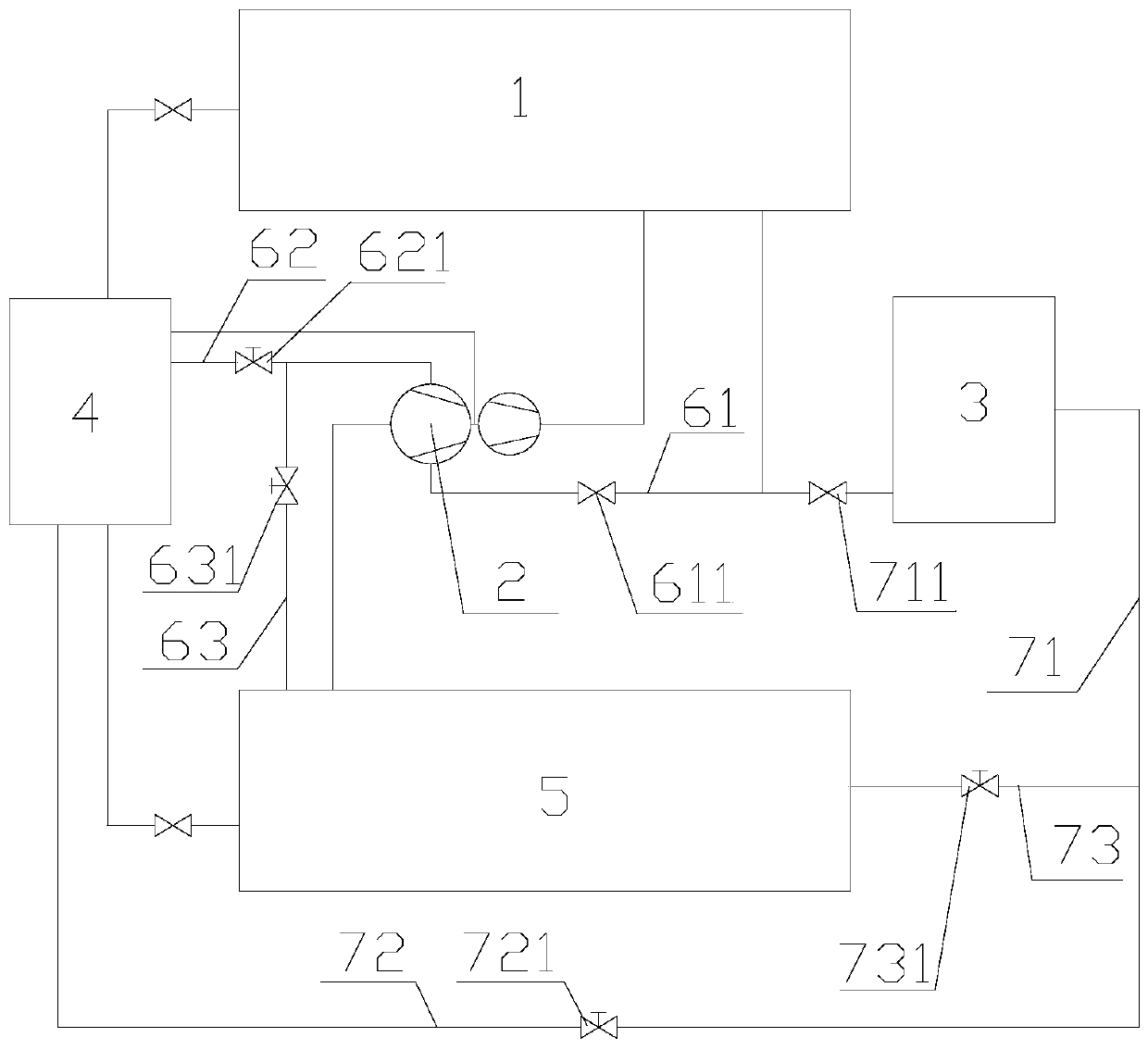

[0025] See also figure 1 As shown, according to an embodiment of the present application, an air conditioning system includes a condenser 1, a flasher 4 and at least one cooling channel. The condenser 1 is connected to the flasher 4 through the cooling channel, and the cooling channel includes a cooling section, The cooling section can cool the components to be cooled. When the air conditioning system is in the first working condition, the cooling medium flows through the cooling section and flows into the flasher 4. By setting the cooling channel, the parts to be cooled are arranged on the cooling section, and the condenser 1 is communicated with the flash generator 4 through the cooling channel, so that proper cooling effect can be achieved under the first working condition, and the reliability of the air conditioning system is improved And performance.

[0026] The air-conditioning system further includes an evaporator 5, and the condenser 1 and the evaporator 5 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com