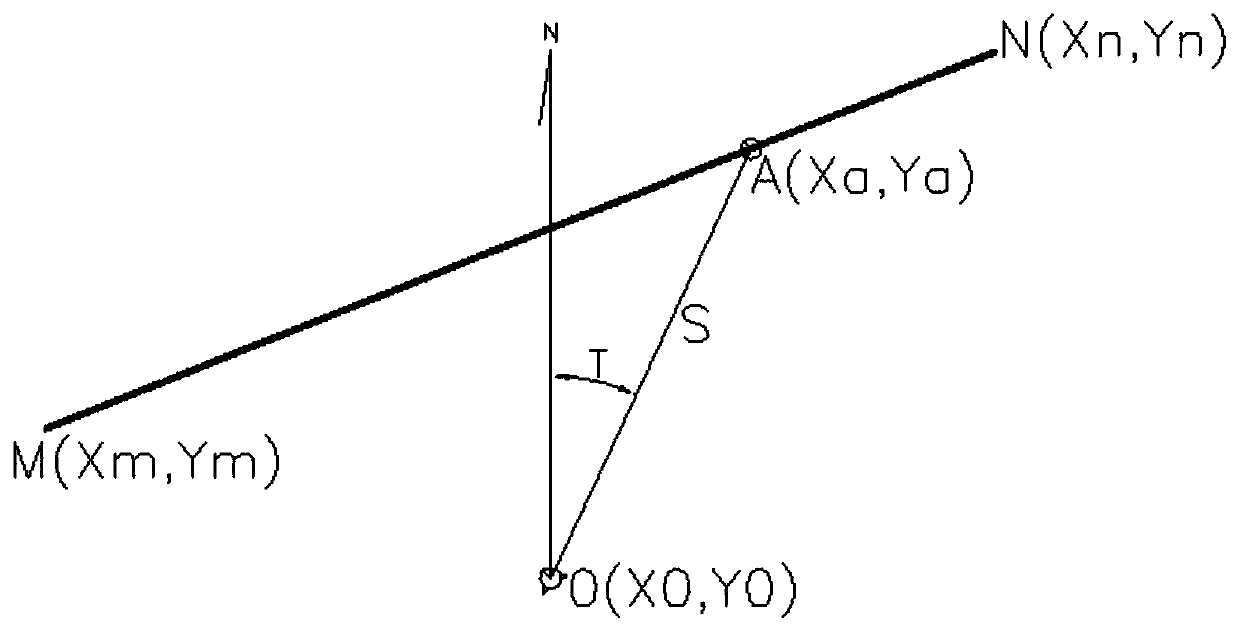

Method for measuring and setting straight line by adopting analytical method

An analytical method, a straight line technology, applied in the field of engineering surveying and mapping, can solve the problems of inconvenience of measuring coordinate positioning straight line, difficult to implement the Cartesian coordinate method, obstructed by obstacles and unable to see through, so as to reduce the probability of human calculation errors and avoid human calculation. Errors, reducing the effect of indirect steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Step 1: Selection of the location and quantity of control points for measurement and release

[0067] Firstly, survey the construction area to select the reasonable position and quantity of control points and leading points. Select the main considerations: 1. Whether there is a clear view between the control points and between the control points and the stakeout line. 2. The coordinates of the control points must be in the same coordinate system as the design coordinates of the straight line to be measured. 3. According to the length of the stakeout straight line, the number of control points is reasonably arranged along the line. The point spacing depends on the nature of the project and the site conditions in accordance with the specific specifications, so I won’t repeat them here.

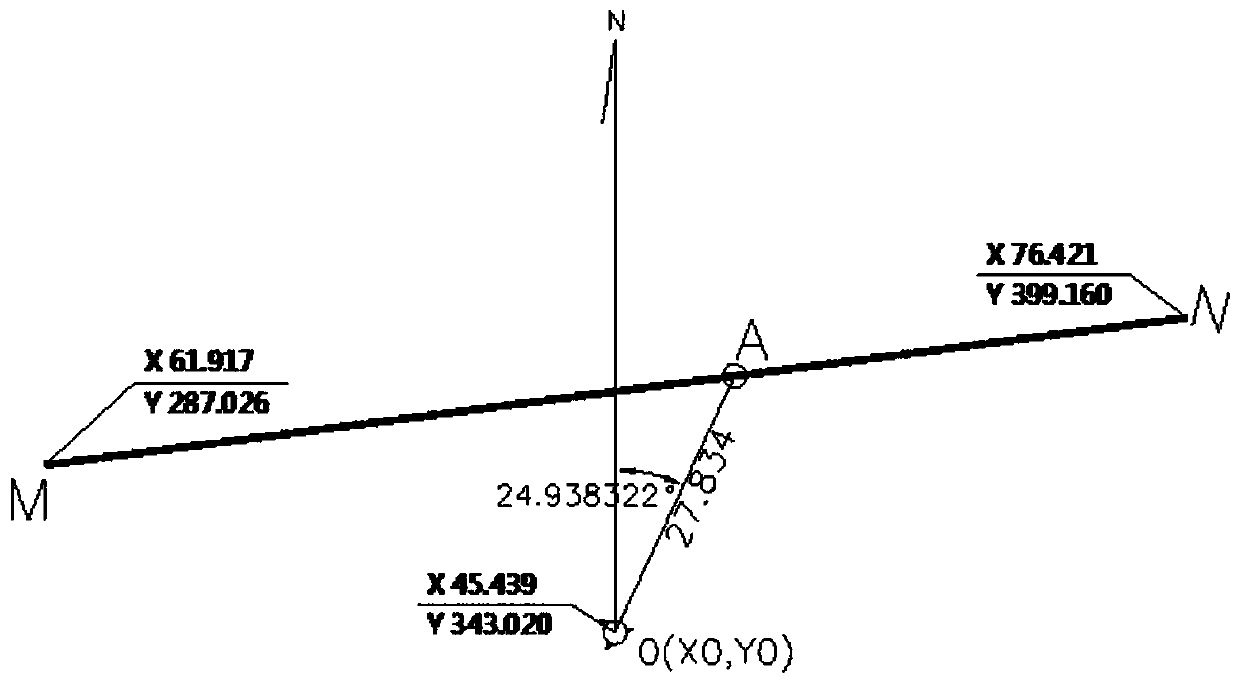

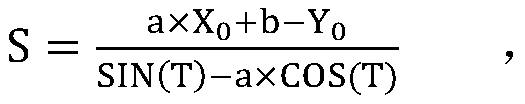

[0068] Step 2: Define the straight line and find the parameters of the straight line

[0069] Collect linear design data. In order to ensure the integrity of the measurement and releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com