Conical coil manufacturing process

A production process and coil technology, which is applied in the field of conical coil production, can solve problems such as the inability to guarantee product dimensional accuracy requirements, cone product height and angular dimension deviation, etc., to meet product design performance requirements, reduce assembly difficulty, The effect of simplifying the staking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following takes a manufacturing process of a conical cooling coil as an example to illustrate, as follows:

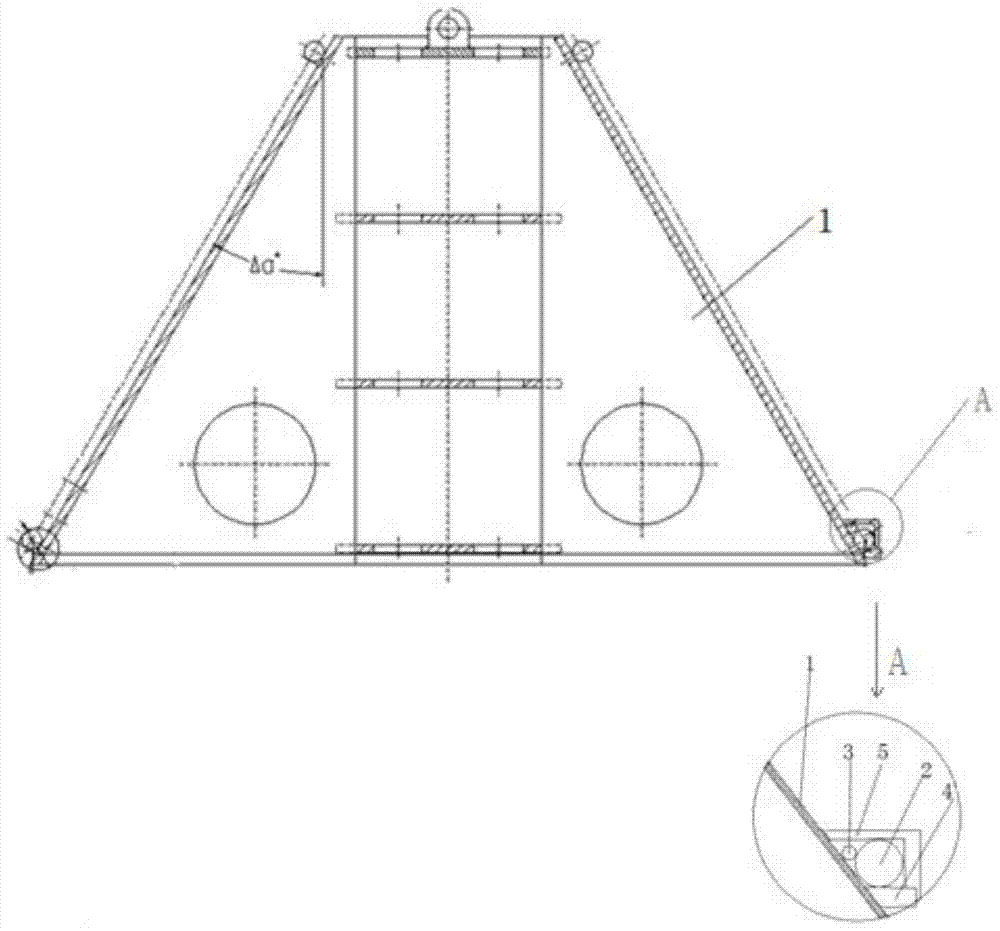

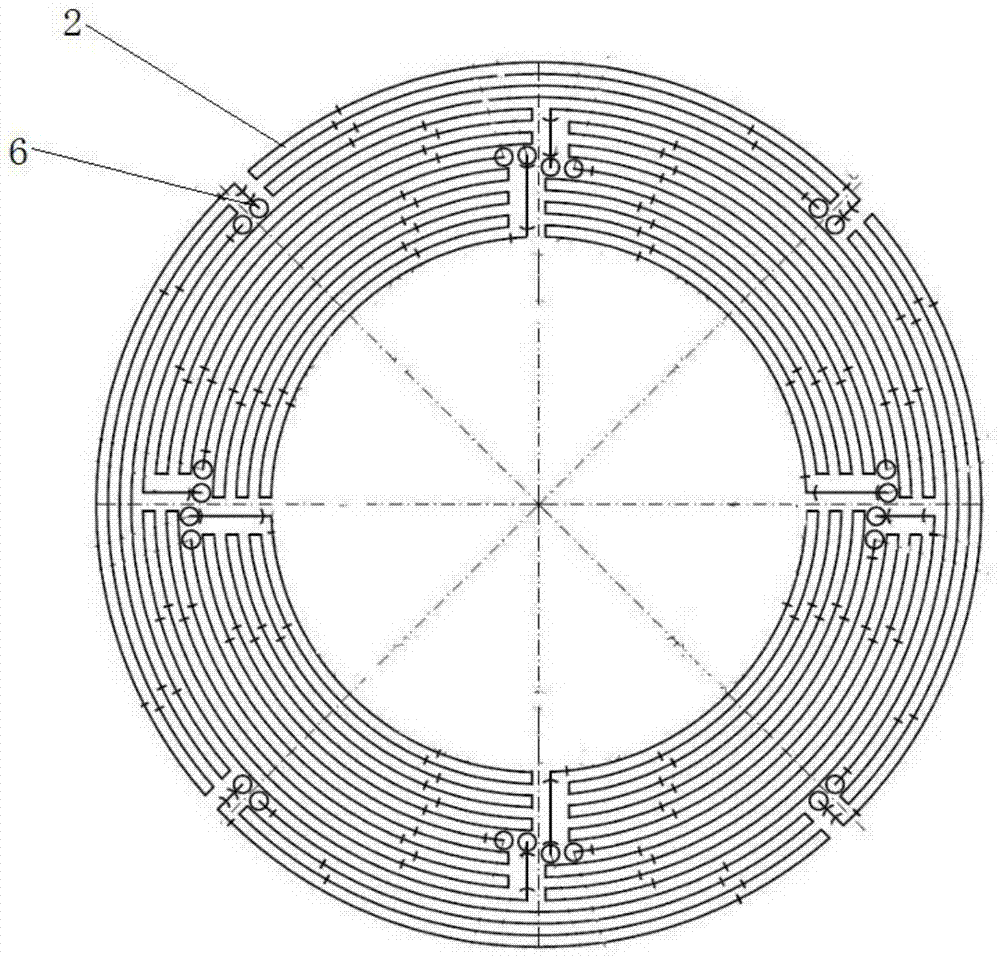

[0019] Such as figure 1 , figure 2 As shown, when making single-coil pipes with different diameters, the diameter of the steel pipe and round steel is selected according to the application of the product, and the length of each group of bent pipe 2 and bent round steel 3 is determined by the sum of the diameter expansion size and the machining allowance And cut off, the cut steel pipe and round steel are bent into bends of different diameters on a special-shaped pipe bender or molded into bends and round steel 3, and the bend 2 or bent round steel 3 is an open Bending into an approximate 360-degree circular ring, the arc length required for the bent pipe 2 or the bent round steel 3 can be cut according to actual needs, generally 1 / 3, 1 / 2 or the length of the entire arc.

[0020] During the design of the tooling cone 1, the shrinkage compensation for weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com