GMM-FBG Alternating Current Sensor Based on Free Energy Model

A technology of GMM-FBG and AC current, which is applied in the direction of gene model, current only measurement, voltage/current isolation, etc., can solve the problems of easy magnetic saturation, increased complexity of sensor system, high measurement error, etc., and achieve accurate identification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0088] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

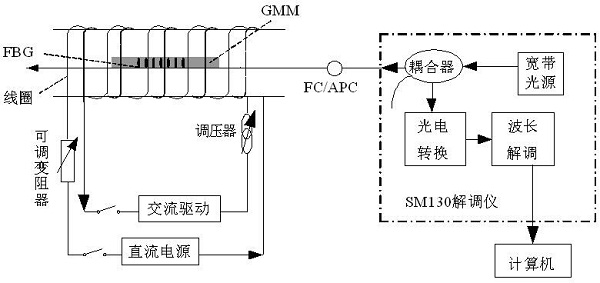

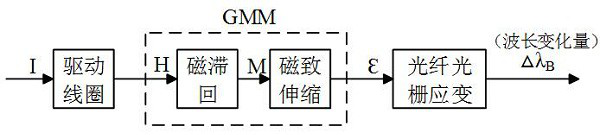

[0089] The invention discloses a GMM-FBG AC current sensor based on a free energy model, and the GMM-FBG AC current sensor system is schematically shown as figure 1 As shown, the Fiber Bragg Grating (Fiber Bragg Grating, FBG) is glued on the surface of the Giant Magnetic Stretch Rod (Giant Magnetostrictive Material, GMM) and placed in a solenoid wound with a coil. The axial stretching effect is generated, which cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com