Current Sensor Based on Magnetic Circuit and Magnetic Fluid

A current sensor and magnetic fluid technology, applied in the field of current sensing, can solve the problem of low current measurement sensitivity, avoid birefringence problems, solve the hysteresis loop, improve conversion efficiency and current measurement sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

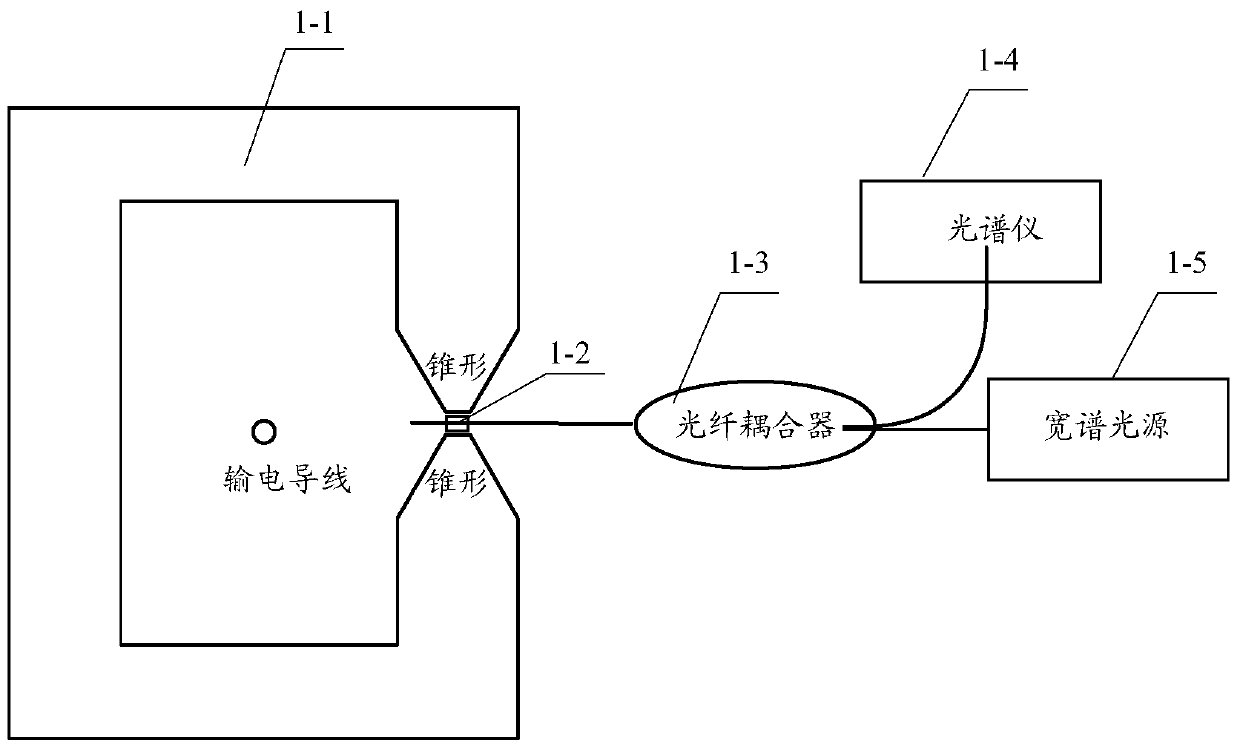

[0044] An application example of the current sensor 100 based on the magnetic circuit and the magnetic fluid of the present invention is described below.

[0045] Such as figure 1 As shown, when the current sensor 100 measures the current, the magnetic conduction circuit 1-1 is set on the measured wire, so that the measured wire passes through the cavity center of the magnetic conduction circuit 1-1, and the magnetic conduction circuit 1-1 is induced to be Measure the current and concentrate the magnetic field generated in the magnetic circuit on the sensor head 1-2. Under the action of a magnetic field, the magnetic fluid will produce a magnetorefractive effect, and its refractive index will change with the change of the magnetic field, which will lead to a change in the optical path of the fiber microcavity, thereby causing the interference spectrum of the fiber microcavity to translate. By detecting the interference spectrum The magnitude of the translation can obtain the ...

application example 2

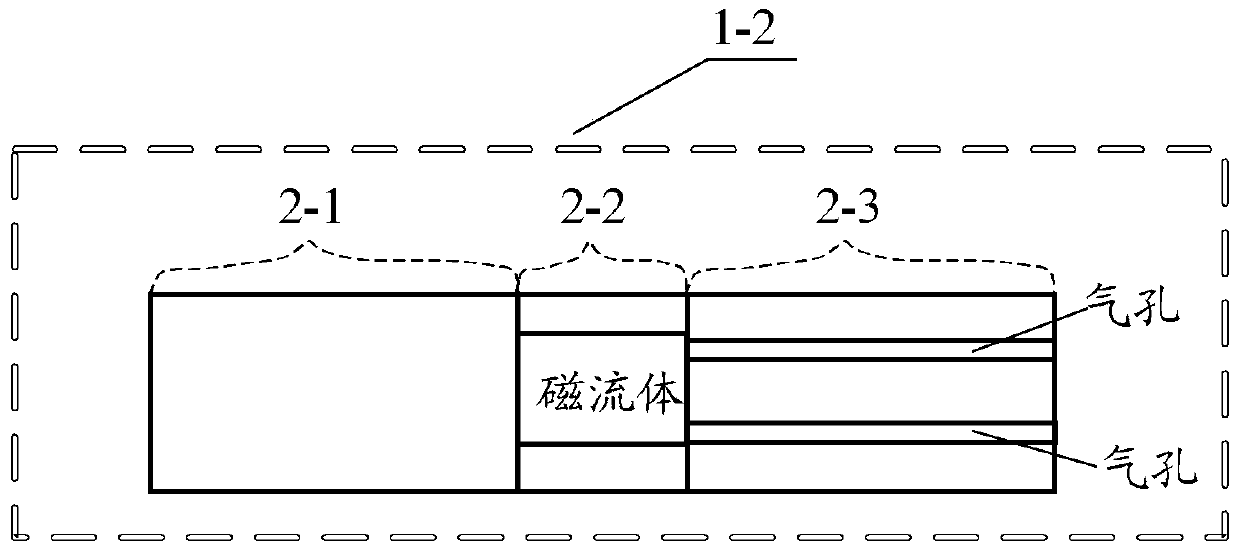

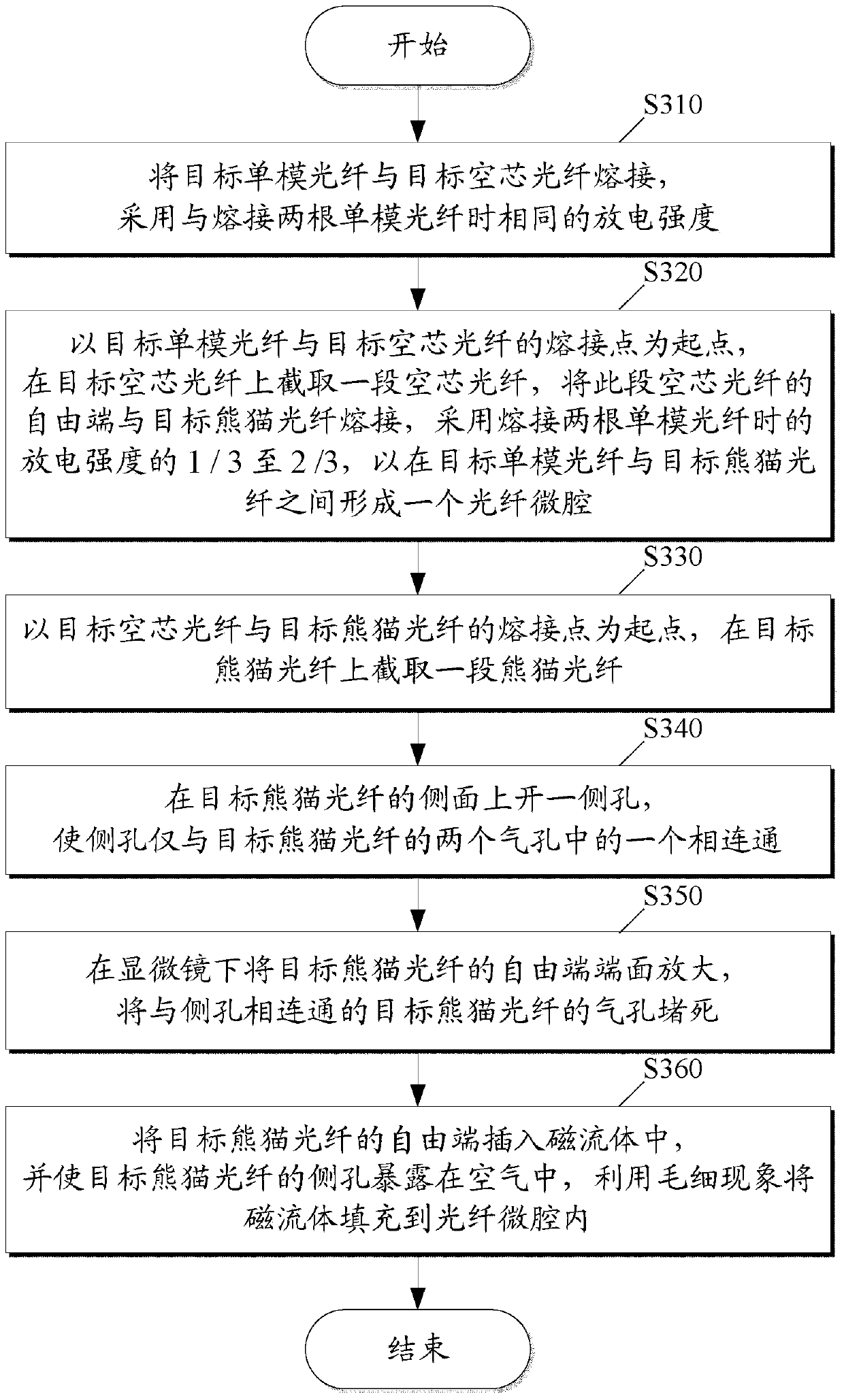

[0055] An application example for making the sensor head of the present invention is described below.

[0056] First, common single-mode fiber (as an example of target single-mode fiber) and hollow-core fiber (as an example of target hollow-core fiber) are fused.

[0057] Then, starting from the fusion point of ordinary single-mode optical fiber and hollow-core optical fiber, cut a section of hollow-core optical fiber with a length between 50 μm and 200 μm on the hollow-core optical fiber, and connect the free end of this section of hollow-core optical fiber to the panda optical fiber (as Example of target Panda fiber) fusion splicing. Among them, the outer diameter of the Panda fiber is the same as that of the ordinary single-mode fiber, which is 125 μm. The diameter of the double hole in the cladding of the Panda fiber is 10 μm-30 μm, and the center-to-center distance of the double hole is 25 μm-60 μm. The discharge intensity used for fusion splicing of hollow core fiber an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com