Lithium ion battery diaphragm breakdown strength testing device and testing method thereof

A technology of lithium-ion battery and breakdown strength, which is applied in the direction of measuring device, testing dielectric strength, measuring device casing, etc., can solve the problem of large access, etc., and achieve the effect of simple operation, high test reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A device for testing the breakdown strength of a lithium-ion battery diaphragm, comprising an insulating working platform 6, a fixing clip 1 for fixing one end of a diaphragm sample 3, a splint 4 for fixing a fixed weight at the other end of the diaphragm sample 3, located at The movable electrode 2 on the upper surface of the diaphragm sample 3 and the fixed electrode 5 located on the lower surface of the diaphragm sample 3 , wherein the movable electrode 2 exerts downward pressure on the diaphragm sample 3 .

[0031] Make a strip-shaped diaphragm sample with a certain area. During the test, one end (longitudinal) of the diaphragm sample 3 should be fixed by the fixing clip 1, and the other end (longitudinal) should be connected to a splint 4 with a fixed weight. The splint can provide 80-500g to the diaphragm (longitudinal) Tensile force, the movable electrode 2 provides 0.8-1kpa pressure in the vertical direction to the diaphragm sample 1 on the fixed electrode 5 due ...

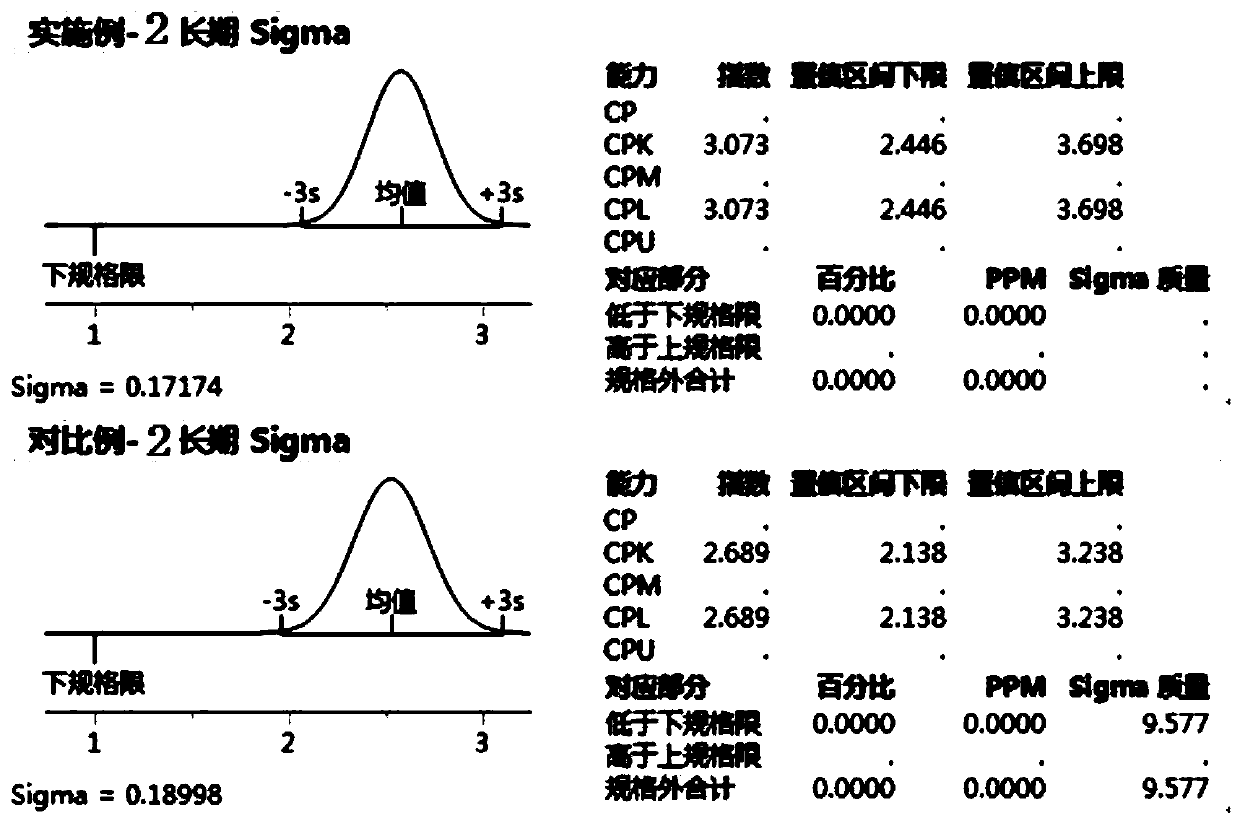

Embodiment 2

[0035] In this embodiment, the fixed electrode 5 is a copper rectangular sheet of 800mm*500mm*5mm (length*width*height), and the movable electrode 2 is cylindrical brass with a smooth surface, a thickness of 2mm, and a diameter of 30mm.

[0036] In this example, a wet-process base film sample made of 9 μm PE is tested, and the specific steps are as follows:

[0037] Step 1, from the same batch of products, a total of 2 diaphragm samples 3 with a length of 1000mm and a width of 300mm were produced;

[0038] Step 2, spreading the diaphragm sample 3 on the fixed electrode 5;

[0039] Step 3, use the diaphragm fixing clip 1 to fix one end of the diaphragm sample 3, and the other end hangs down naturally through the fixed rotating shaft, and uses the splint 4 with a weight of 300g to clamp the naturally hanging end of the diaphragm sample 3;

[0040] Step 4, after the splint 4 is stabilized, place the movable electrode 2 on the diaphragm sample 3;

[0041] Step 5, the movable ele...

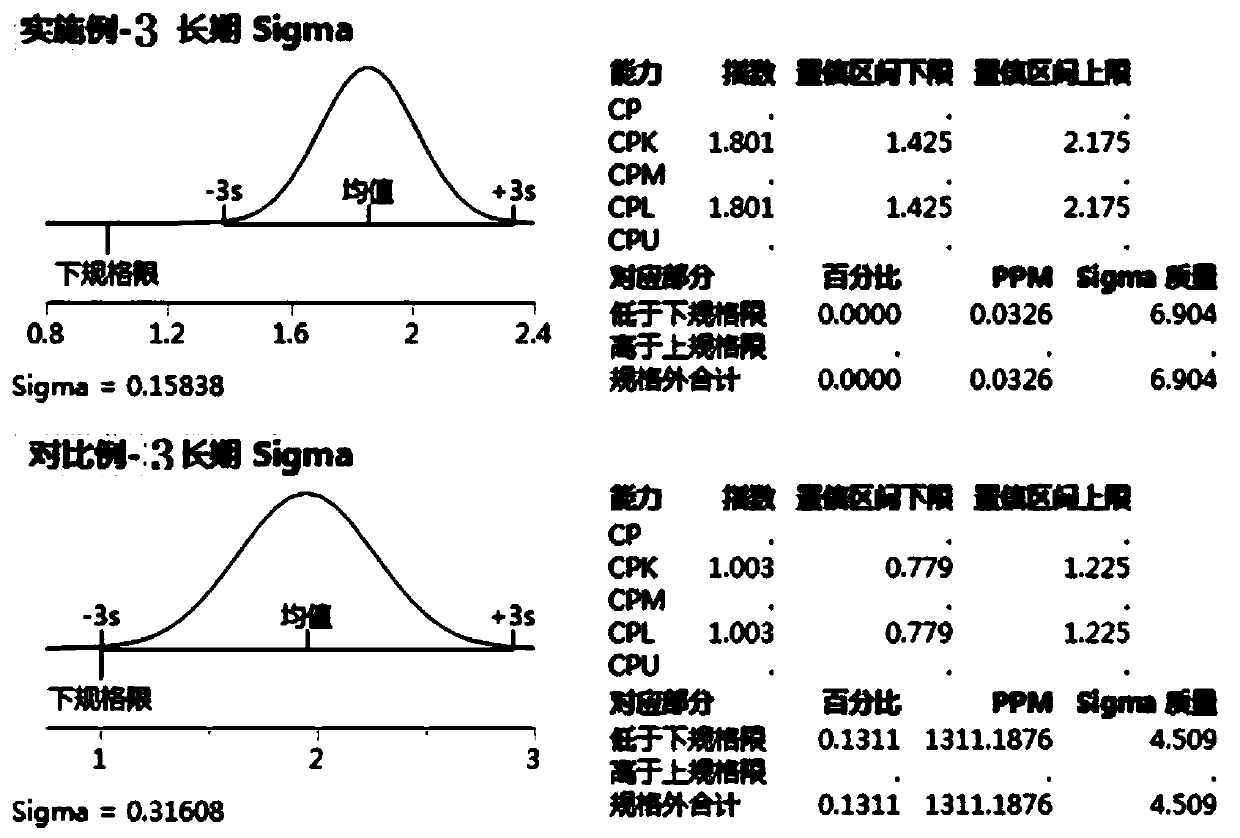

Embodiment 3

[0049] On the basis of Example 2, a wet-process base film with a thickness of 12 μm was selected and tested by the same method. At the same time, the device and method with the notification number CN104090217A were used to test the 12 μm thick PE material wet-process base film for testing, and the results obtained were the breakdown data of Comparative Example 3 in Table 2.

[0050] Table 2 is the breakdown voltage data / KV that comparative example 3 and embodiment 3 obtain

[0051]

[0052]

[0053] The result of data processing is shown in Fig. figure 2 Shown, the CPK value of comparative example 3 is 1.003, and the CPK value of embodiment 3 is 1.801.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap