Magnetic moment correction method

A correction method and magnetic moment technology, applied in the direction of the magnitude/direction of the magnetic field, magnetic performance measurement, measuring devices, etc., can solve the problems of cumbersome metal processing and difficulty in satisfying users, and achieve the effect of avoiding correction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be fully described below in conjunction with specific examples.

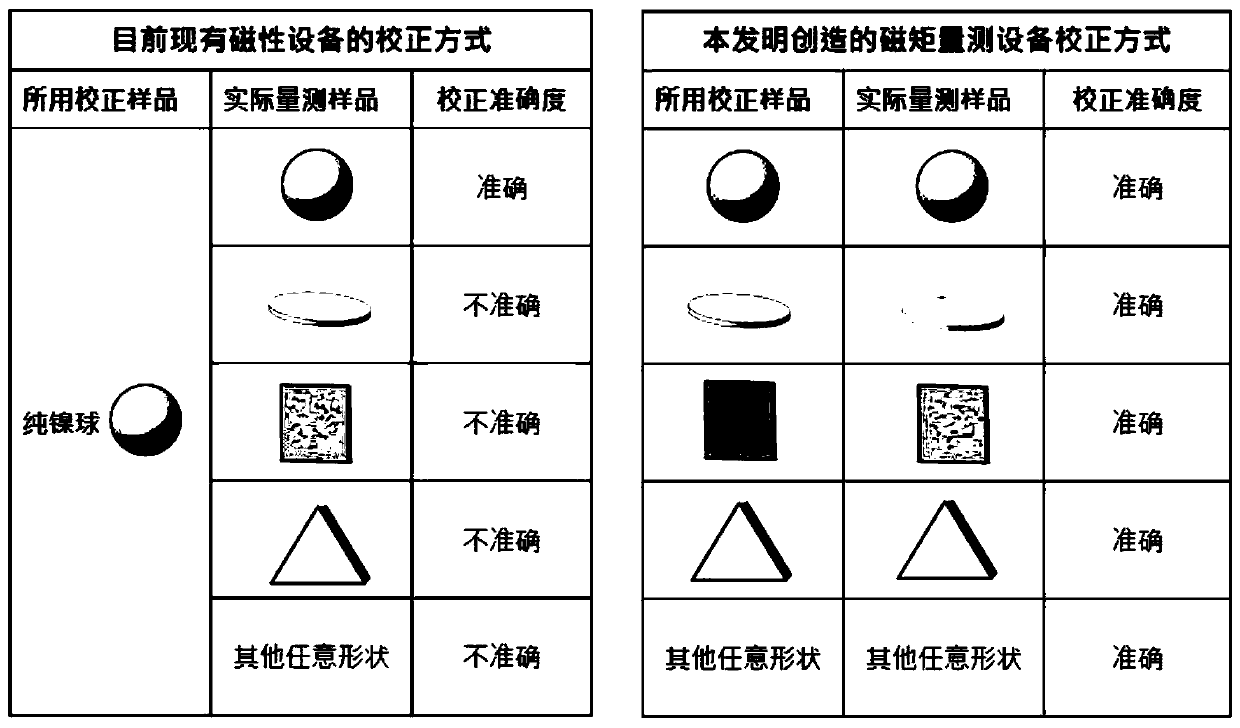

[0029] The superconducting quantum interference magnetometer or vibrating sample magnetometer equipment currently used to measure the basic physical parameters of magnetic materials are collectively referred to below as magnetic measurement equipment. During the use of magnetic measuring equipment, there is an error problem between a single standard calibration sample and a variety of non-standardized samples to be tested. Magnetic moment calibration is to calibrate the magnetic measuring equipment with a magnetic calibration sample whose magnetic moment is known, so as to prepare for the accurate determination of the magnetic moment value of the sample to be tested.

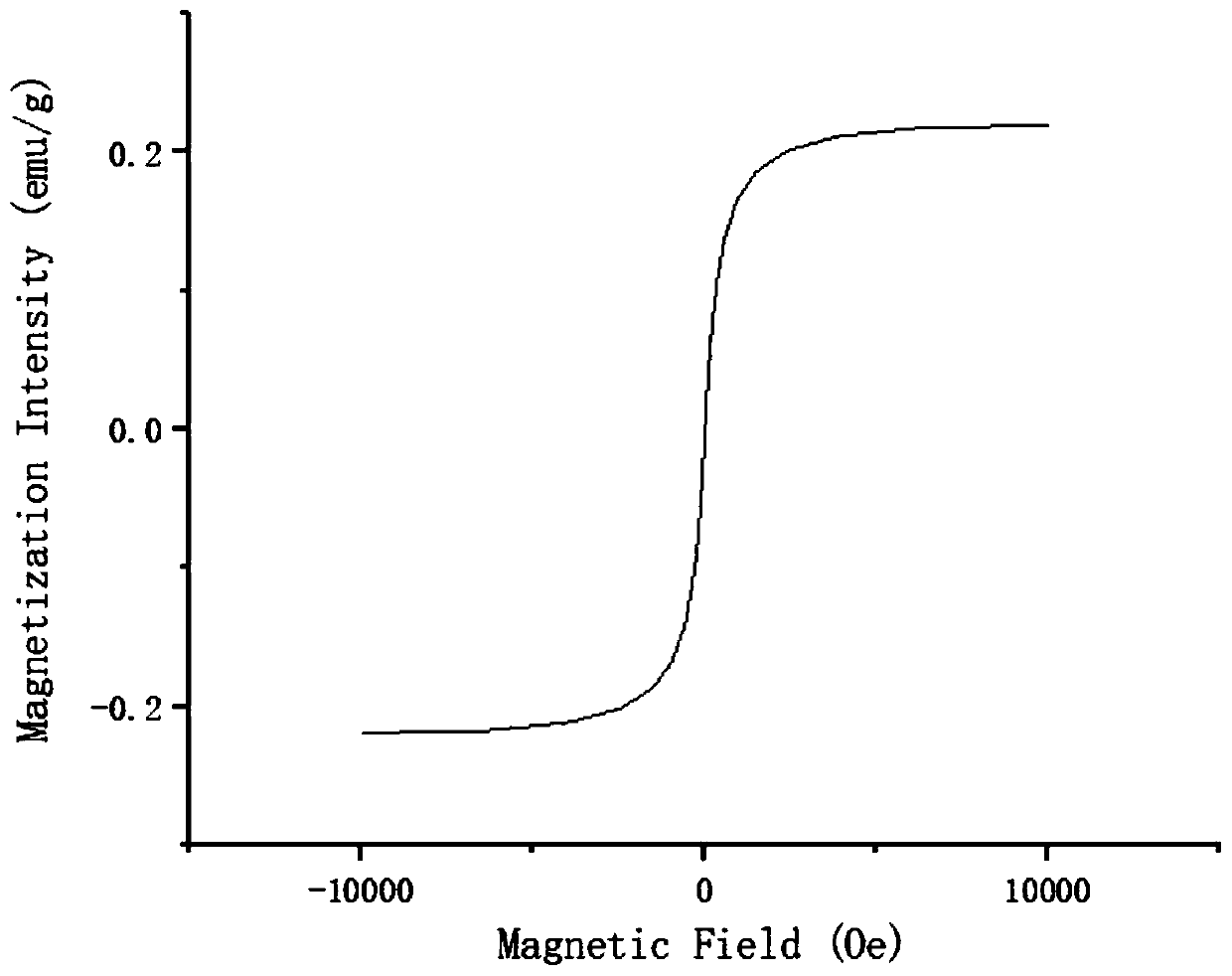

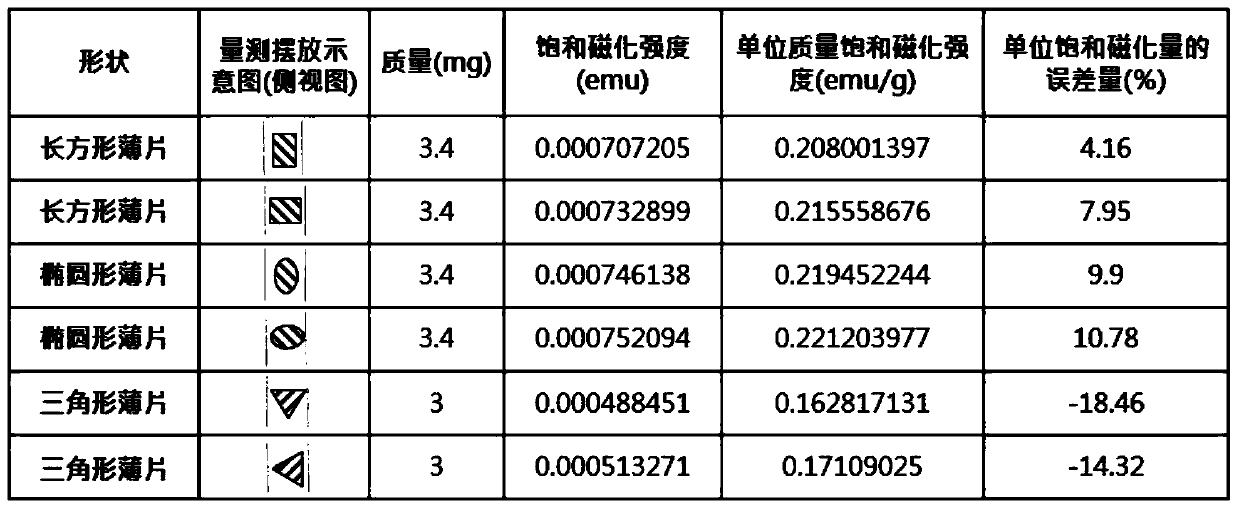

[0030] We confirmed the influence of the error we mentioned in the actual measurement. We used steps S1 and S2 to prepare elliptical slices, rectangular slices and triangular slices, and used the calibrated superc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com