Automatic evaluation method and system for width quality of hot-rolled strip steel

A technology of hot-rolled strip and evaluation method, which is applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of easy missed inspection, high labor cost, low accuracy rate, etc., so as to reduce the missed inspection rate. , the effect of improving labor efficiency and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

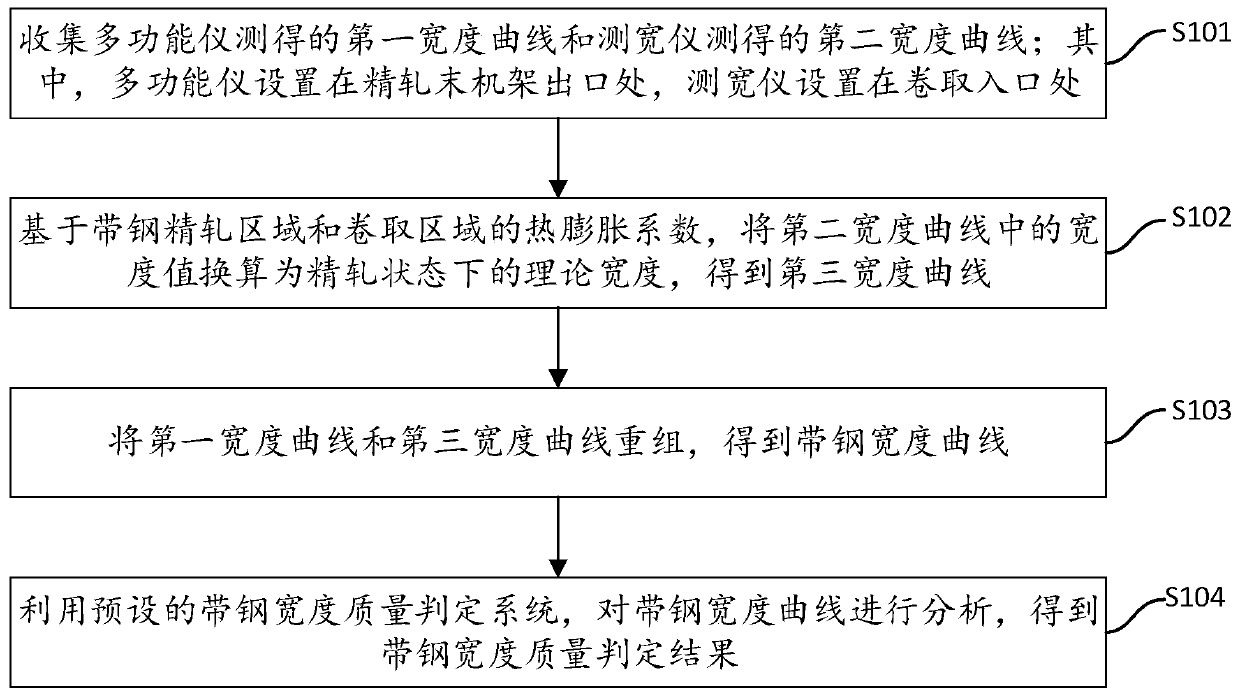

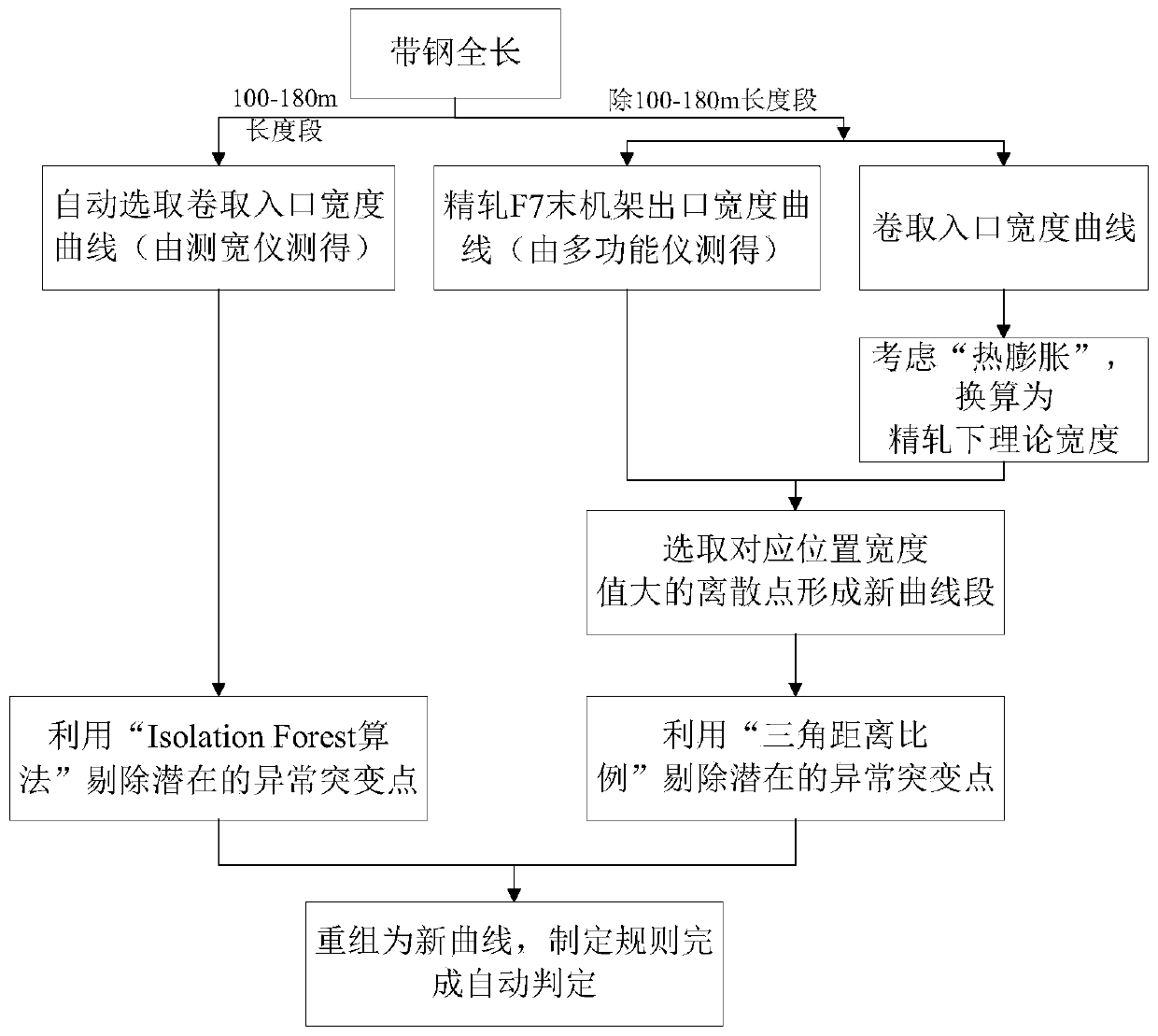

[0065] see Figure 1 to Figure 2 , the present embodiment provides a method for automatically evaluating the width quality of hot-rolled strip steel, and the method for automatically evaluating the width quality of hot-rolled strip steel includes:

[0066] S101, collecting the first width curve measured by the multifunctional instrument and the second width curve measured by the width measuring instrument; wherein, the multifunctional instrument is set at the exit of the finishing stand, and the width measuring instrument is set at the coiling entrance;

[0067] It should be noted that the acquisition method of the width of the hot-rolled strip steel by the multi-function instrument and the width measuring instrument is periodic sampling, and the width measurement value is recorded every 1m through time-length sequence conversion, and the obtained measurement data Save according to the preset format.

[0068] S102, based on the coefficient of thermal expansion of the strip fi...

no. 2 example

[0108] This embodiment provides an automatic evaluation system for the width and quality of hot-rolled strip steel. The automatic evaluation system for the width and quality of hot-rolled strip steel includes:

[0109] The strip width curve acquisition module is used to collect the first width curve measured by the multifunctional instrument and the second width curve measured by the width measuring instrument; wherein, the multifunctional instrument is arranged at the exit of the finishing stand, and the The width measuring instrument is set at the coiling entrance;

[0110] A curve conversion module, configured to convert the width value in the second width curve into a theoretical width in a finish rolling state based on the coefficient of thermal expansion of the strip finish rolling area and the coiling area, to obtain a third width curve;

[0111] a curve recombination module, configured to recombine the first width curve and the third width curve to obtain a strip width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com