Liquid cooling head and liquid cooling type heat dissipation system

A liquid-cooled head and heat-dissipating unit technology, used in instruments, electrical digital data processing, electrical components, etc., can solve the problems of accelerating heat exchange, accelerating the collision of cooling fins, and turbulent manufacturing effects, so as to improve heat absorption. Efficiency, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

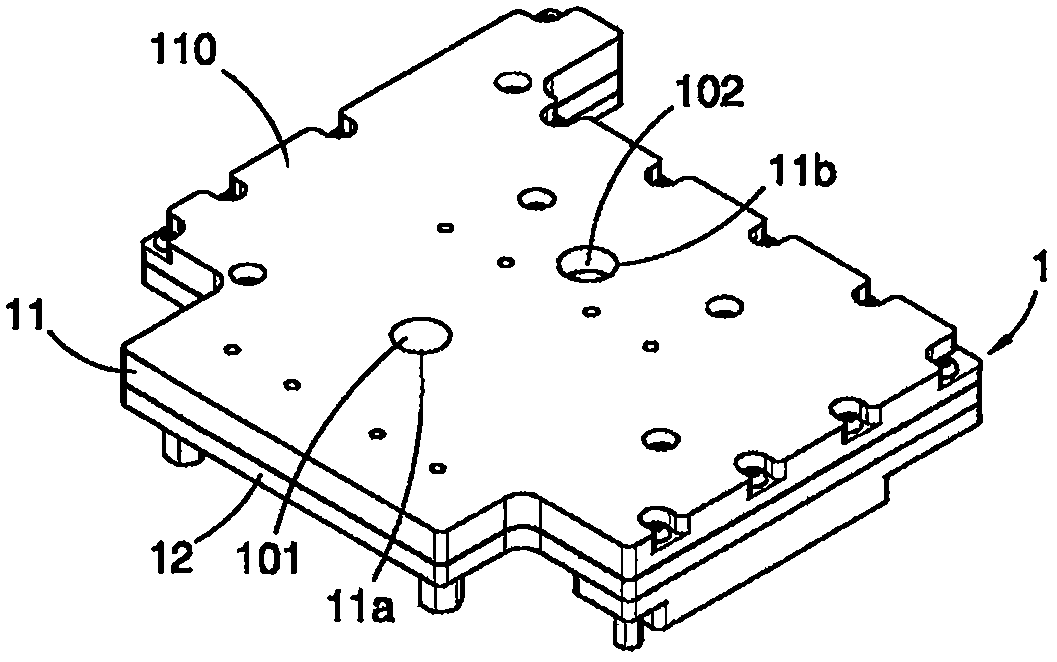

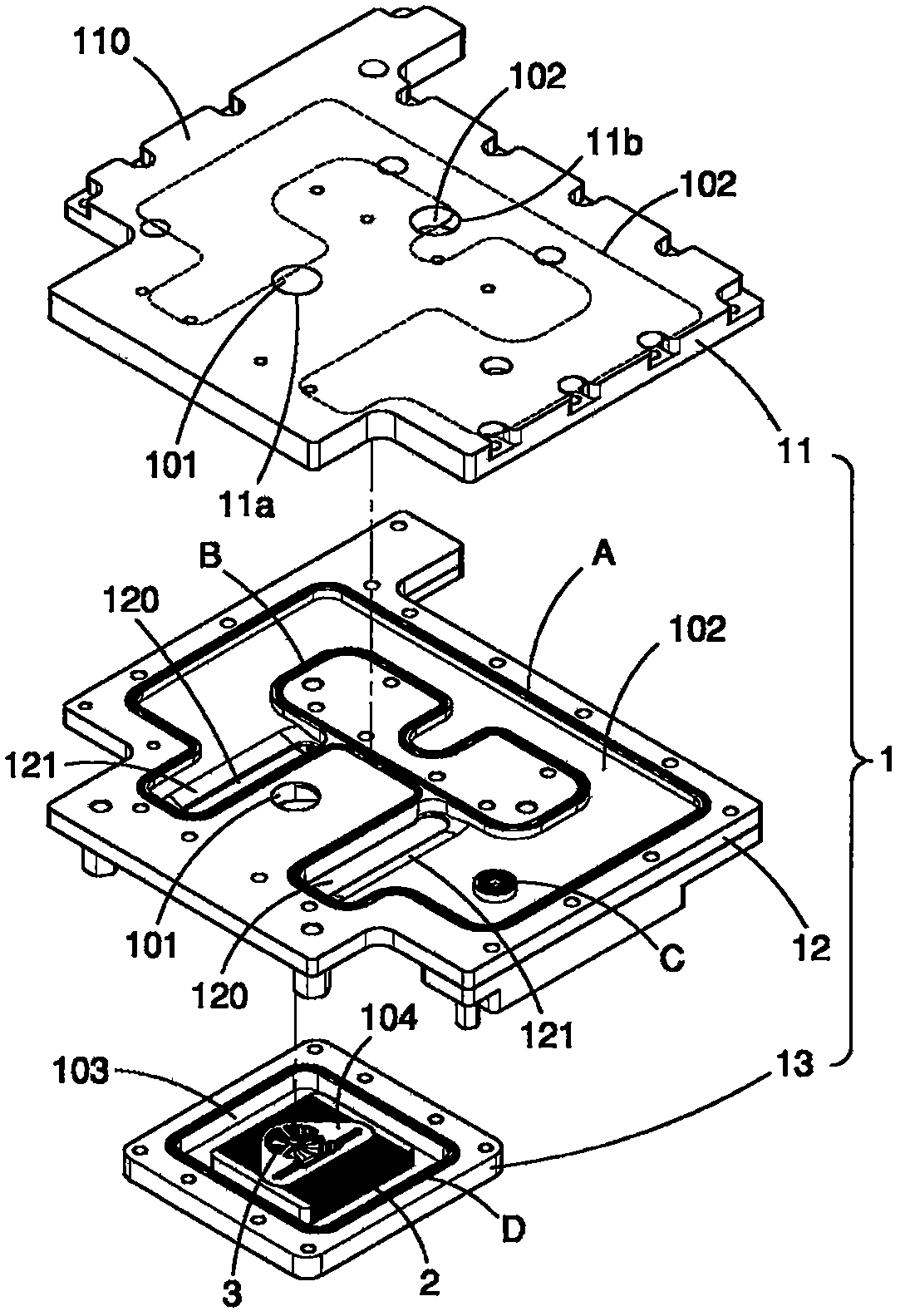

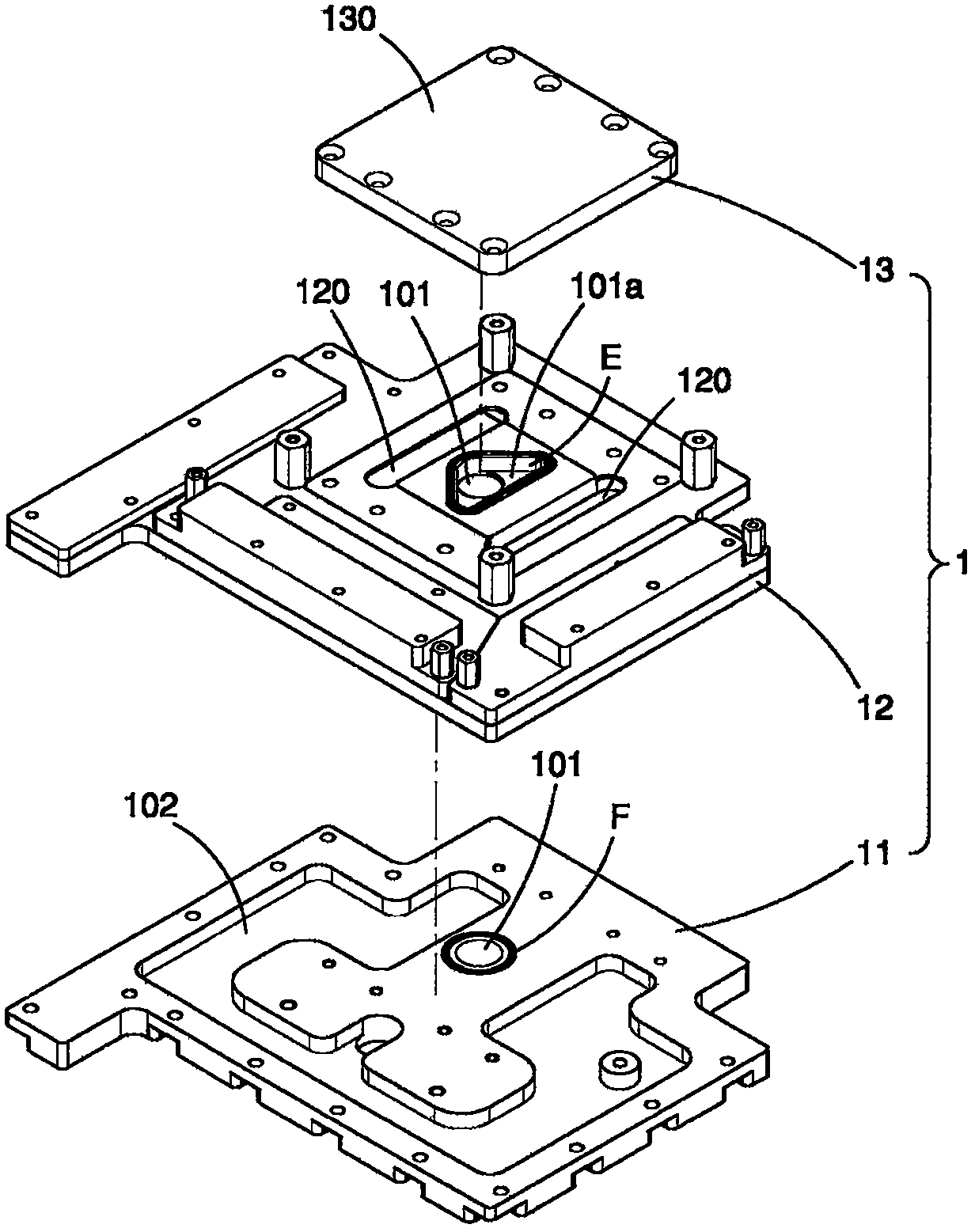

[0072] figure 1 , figure 2 It is a three-dimensional appearance view and a three-dimensional exploded view of a preferred embodiment of the liquid cooling head of the present invention, which includes a heat conduction body 1 , a heat dissipation unit 2 , and a rotating device 3 . The heat-conducting body 1 can be made of heat-conducting metal, such as copper or aluminum, which has an inlet channel 101 for introducing cooling fluid (not shown in the figure), an outlet channel 102 for exporting cooling fluid, and connecting the inlet channel. The channel 101 and a heat exchange area 103 leading out of the flow channel 102 .

[0073] In this embodiment, for ease of assembly, as figure 2 As shown, the heat conducting body 1 includes a first block 11 , a second block 12 , and a third block 13 stacked in sequence. These blocks 11-13 are closely connected together by a plurality of bolt assemblies (not shown in the figure), and utilize the arrangement of a plurality of sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com