A kind of preparation method of interface modified cathode material for lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of preparation of interface-modified positive electrode materials, can solve problems such as poor rate performance, poor charge and discharge stability, and cycle capacity decay, and achieve increased rate performance, improved cycle performance, and reduced interface impedance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

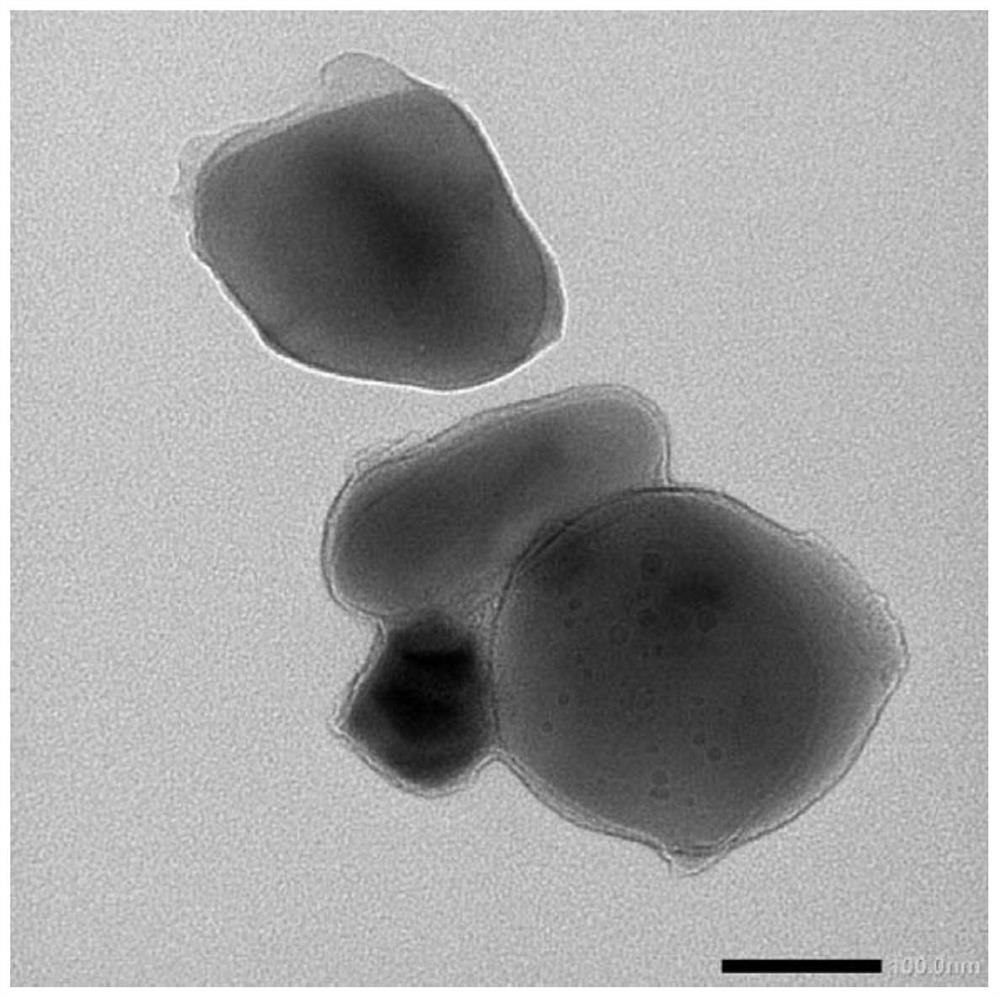

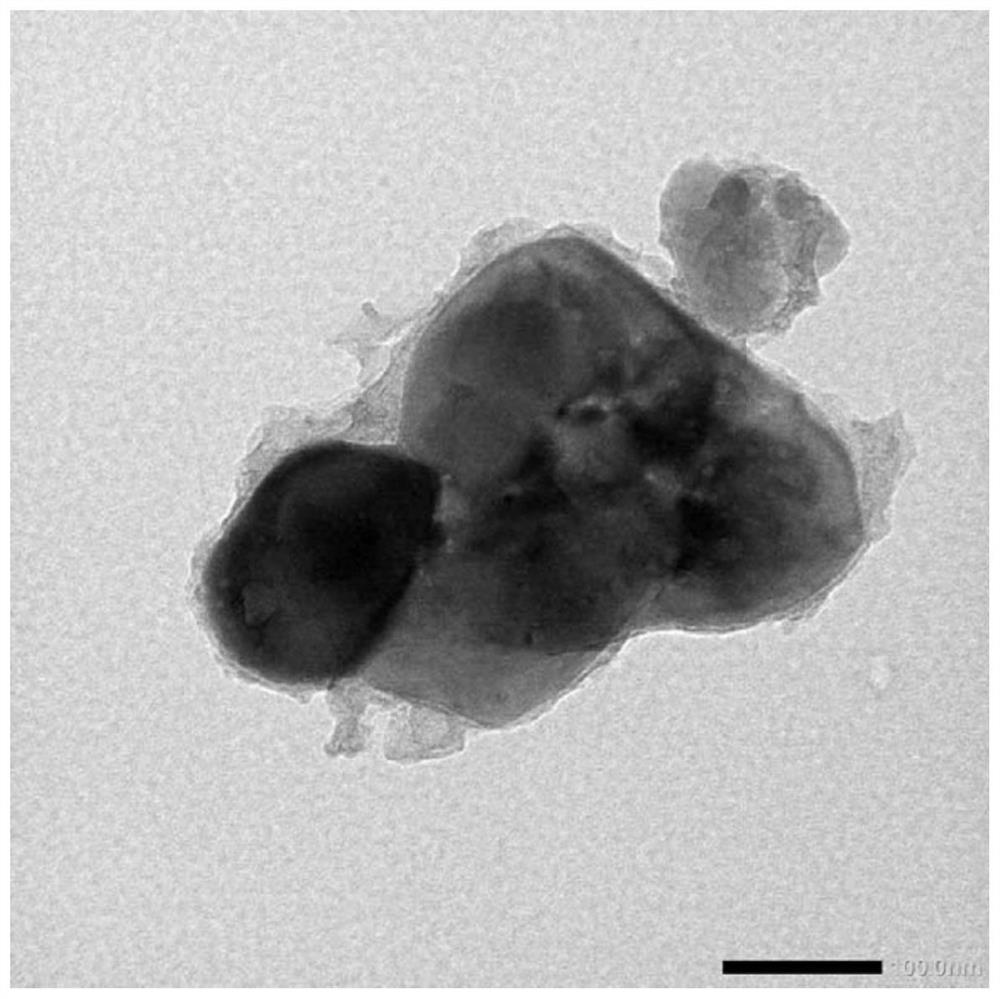

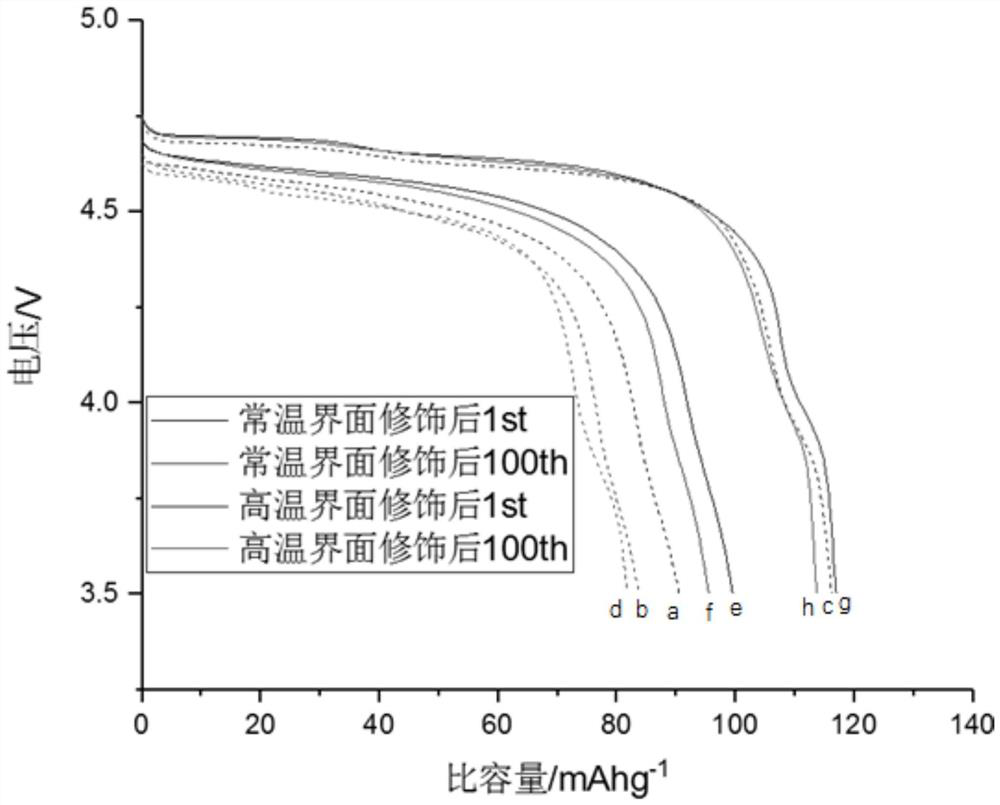

[0057] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

[0058] The preparation method of the interface modification positive electrode material for lithium ion battery provided by the invention comprises the following steps:

[0059] Step 1, preparing positive electrode material;

[0060] The cathode material is a conventional cathode material for lithium-ion batteries, such as LiCoO 2 、LiFePO 4 、Li(NiCoMn) 1 / 3 o 2 、LiNi 0.5 mn 1.5 o 4 or LiMn 2 o 4 Wait;

[0061] Step 2, preparing metal salt solution;

[0062] dissolving the soluble metal salt in a volatile solvent to obtain a metal salt solution;

[0063] The above-mentioned volatile solvent can specifically be absolute ethanol, and the metal salt can specifically be aluminum salt, magnesium salt or titanium salt, etc.;

[0064] Step three, decentralized processing;

[0065] Dispersing the positive electrode material in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com