Single-phase five-level rectifier based on t-type structure

A five-level rectifier technology, applied in electrical components, high-efficiency power electronic conversion, output power conversion devices, etc., can solve the problem of large number of switches in five-level converters, large three-level voltage stress, and low power density. problem, achieve the effect of realizing multi-level rectification, reducing failure loss and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

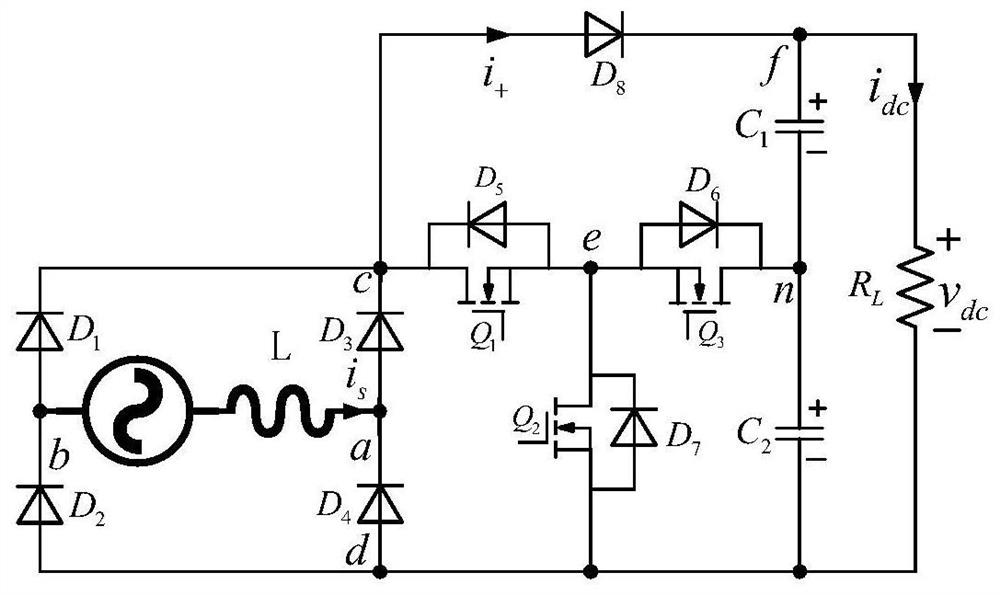

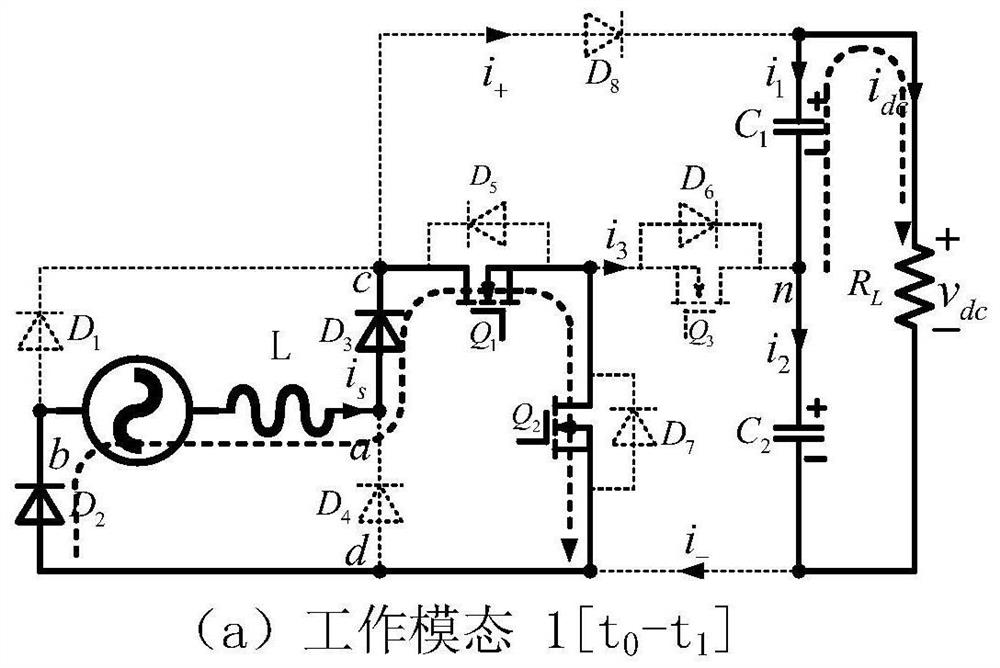

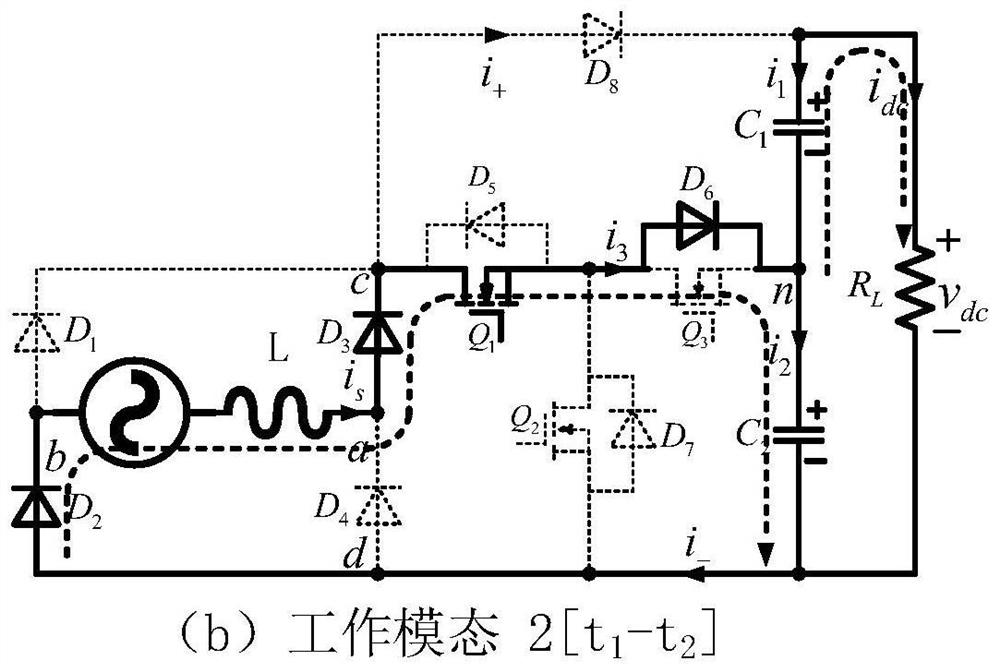

[0043] Such as figure 1 As shown, a single-phase five-level rectifier based on a T-shaped structure, including an inductor L, a switch tube Q 1 , Q 2 , Q 3 , Diode D 1 ~D 8 , capacitance C 1 、C 2 ;

[0044] AC power V S One side is respectively connected to the diode D 1 anode, diode D 2 a cathode, the connection node forming terminal b;

[0045] AC power V S The other side is connected to one end of the inductor L, and the other end of the inductor L is respectively connected to the diode D 3 anode, diode D 4 Cathode, the other end of inductor L and diode D 3 、D 4 connect the nodes to form endpoint a;

[0046] Switch tube Q 1 The drains are connected to the diode D 1 cathode, diode D 3 cathode, diode D 8 anode, switching tube Q 1 Drain and Diode D 1 、D 3 、D 8 connect the nodes to form the endpoint c;

[0047] Switch tube Q 2 The source is connected to the diode D respectively 2 anode, diode D 4 anode, switching tube Q 2 source and diode D 2 、D 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com