A mask cleaning device

A cleaning device and mask technology, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems that affect the use, and the masks with holes are not easy to be cleaned thoroughly. To achieve the effect of good cleaning, fast and effective cleaning, and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

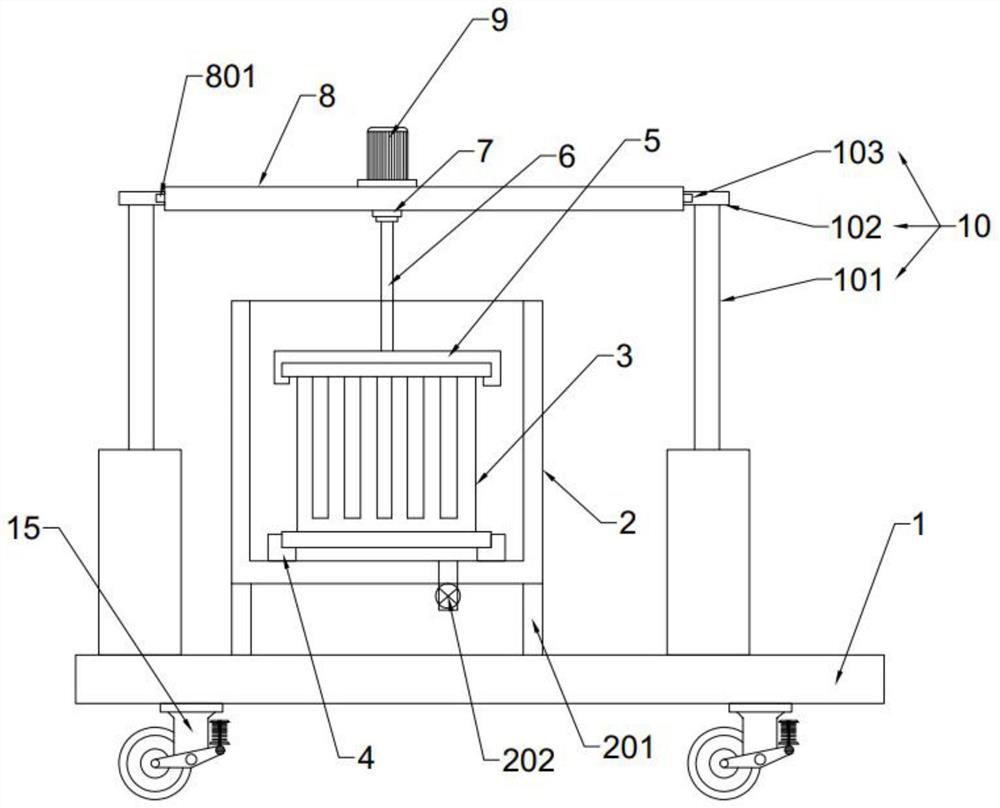

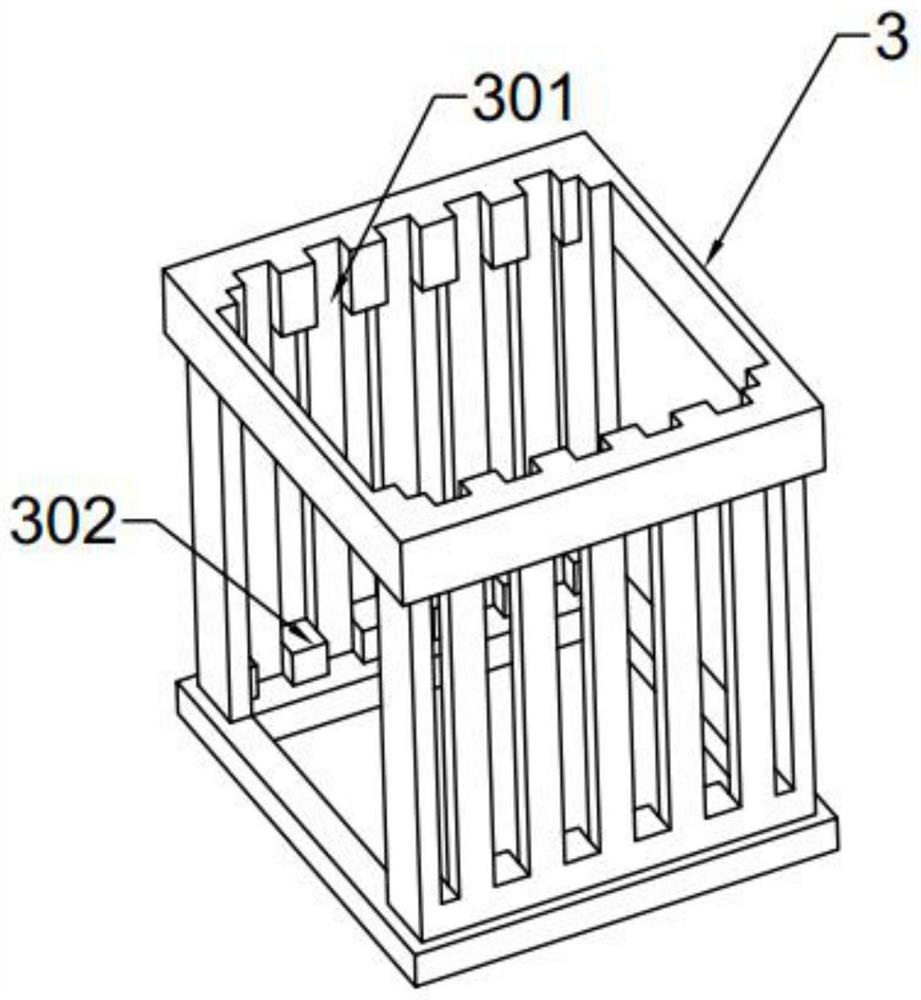

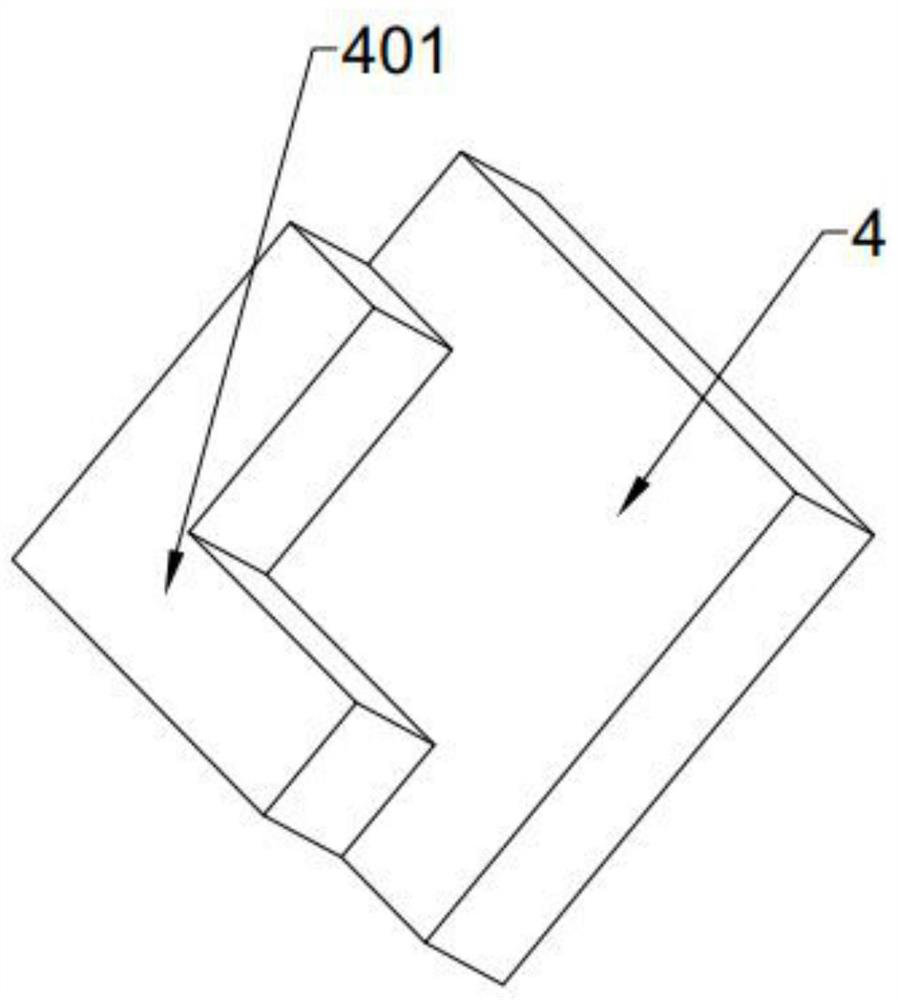

[0040]A cleaning device for a mask plate, comprising a fixing base 1, a cleaning tank 2 is fixedly arranged on the fixing base 1, a cleaning frame 3 is arranged in the cleaning tank 2, and a plurality of groups of insertion grooves 301 are arranged in the cleaning frame 3 for inserting A mask plate is provided, wherein the mask plate is inserted into the insertion slot 301 formed by the two adjacent limit blocks, and the bottom of the cleaning frame 3 is clamped and fixed with the cleaning tank 2 through the fixed support 4; the cleaning frame 3 can be The frame cover 5 is disassembled and fixed, and the center of the frame cover 5 is fixedly connected with a connecting shaft 6, and the top of the connecting shaft 6 is connected with a top plate 8 through a bearing 7, and a servo motor is fixedly installed on the top plate 8 as the power to drive the connecting shaft 6 to rotate. In the device 9 , the output shaft of the servo motor is fixedly connected to the connecting shaft ...

Embodiment 2

[0054] A cleaning device for a mask plate, comprising a fixing base 1, a cleaning tank 2 is fixedly arranged on the fixing base 1, a cleaning frame 3 is arranged in the cleaning tank 2, and a plurality of groups of insertion grooves 301 are arranged in the cleaning frame 3 for inserting A mask plate is set, the bottom of the cleaning frame 3 is clamped and fixed with the cleaning tank 2 through the fixed support 4; the cleaning frame 3 is detachably installed and fixed with a frame cover 5, and the center of the frame cover 5 is fixedly connected with a connecting shaft 6, and the connecting shaft 6 The top is rotatably connected with a top plate 8 through a bearing 7, and a servo motor is fixedly installed on the top plate 8 as a power device 9 that drives the connecting shaft 6 to rotate. The output shaft of the servo motor is fixedly connected with the connecting shaft 6 through a shaft sleeve; A lifting device 10 is installed, and the top of the lifting device 10 is clamped...

Embodiment 3

[0069] A cleaning device for a mask plate, comprising a fixing base 1, a cleaning tank 2 is fixedly arranged on the fixing base 1, a cleaning frame 3 is arranged in the cleaning tank 2, and a plurality of groups of insertion grooves 301 are arranged in the cleaning frame 3 for inserting A mask plate is set, the bottom of the cleaning frame 3 is clamped and fixed with the cleaning tank 2 through the fixed support 4; the cleaning frame 3 is detachably installed and fixed with a frame cover 5, and the center of the frame cover 5 is fixedly connected with a connecting shaft 6, and the connecting shaft 6 The top is rotatably connected with a top plate 8 through a bearing 7, and a servo motor is fixedly installed on the top plate 8 as a power device 9 that drives the connecting shaft 6 to rotate. The output shaft of the servo motor is fixedly connected with the connecting shaft 6 through a shaft sleeve; A lifting device 10 is installed, and the top of the lifting device 10 is clamped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com