Reinforcing rib plate welding device of bumper welding device

A rib plate and welding device technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of low welding accuracy, difficult welding of rib plates, low fusion welding efficiency, etc. The effect of avoiding loosening and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

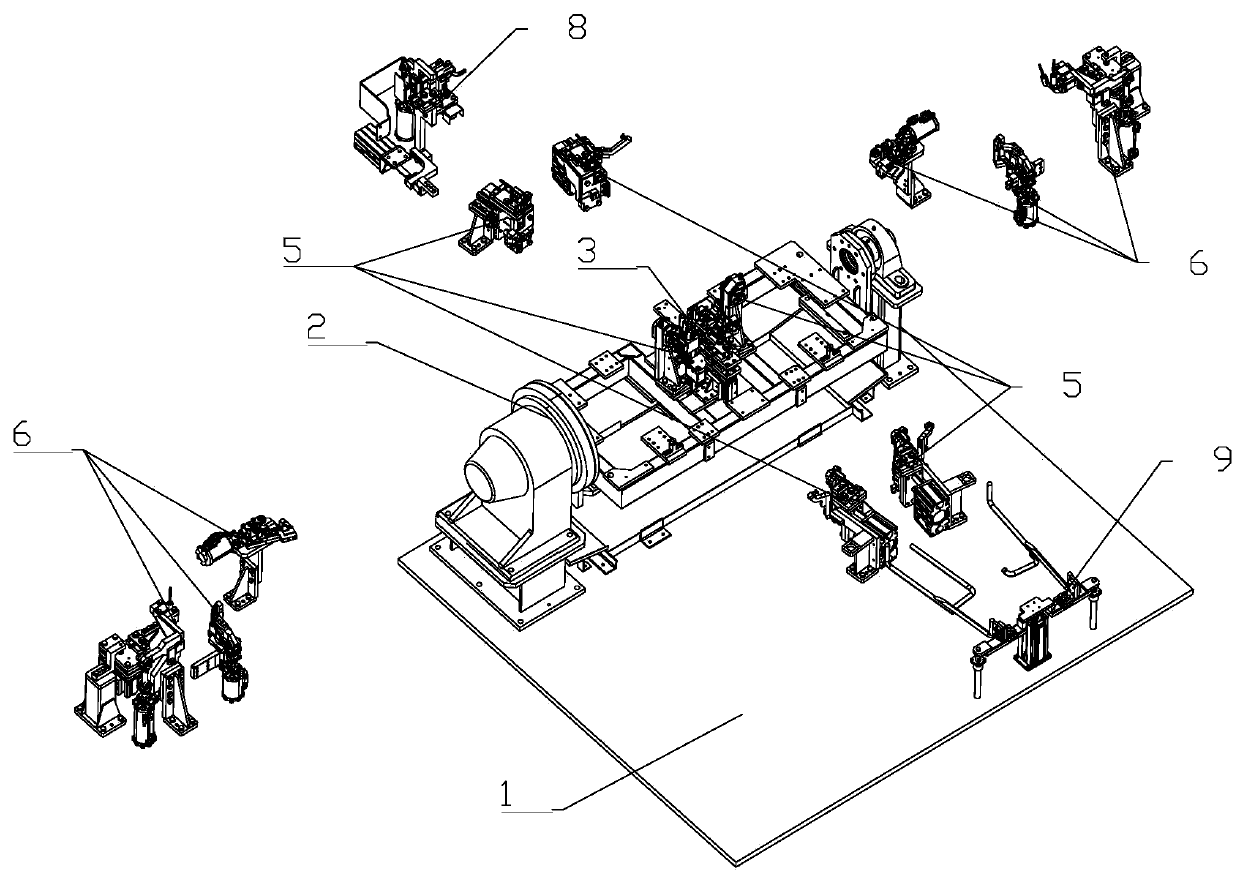

[0023] Such as figure 1 As shown, a bumper welding device includes a frame 1, a rotating assembly 2, an intermediate positioning device 3, a rib plate welding device 4, a connecting plate welding device 6, a hook positioning fixture device 8, a blanking device 9 and a welding robot; The rotating assembly 2 is installed on the frame 1; the intermediate positioning device 3 is installed in the middle of the rotating assembly 2, the rib plate welding device 4 is installed on the rotating assembly 2, and the rib plate welding device 4 is located in the middle On both sides of the device 3, the connecting plate welding device 6 is installed at both ends of the rotating assembly 2; the hook positioning fixture device 8 is installed on the rotating assembly 2 and is located on the side of the intermediate positioning device 3. The blanking device 9 is installed on the other side of the intermediate positioning device 3; the welding robot is installed on the frame 1.

[0024] The int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com