Construction method of annular cable-supported grid structure with upper grid participating in balancing inhaul cable pretension

A kind of cable pre-tension and grid structure technology, applied in building construction, building material processing, construction and other directions, can solve the problems of high cost of tire frame measures, unfavorable loop cable spreading and lifting and installation, etc., and achieve high efficiency. And high-precision construction molding, reducing the effect of structural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

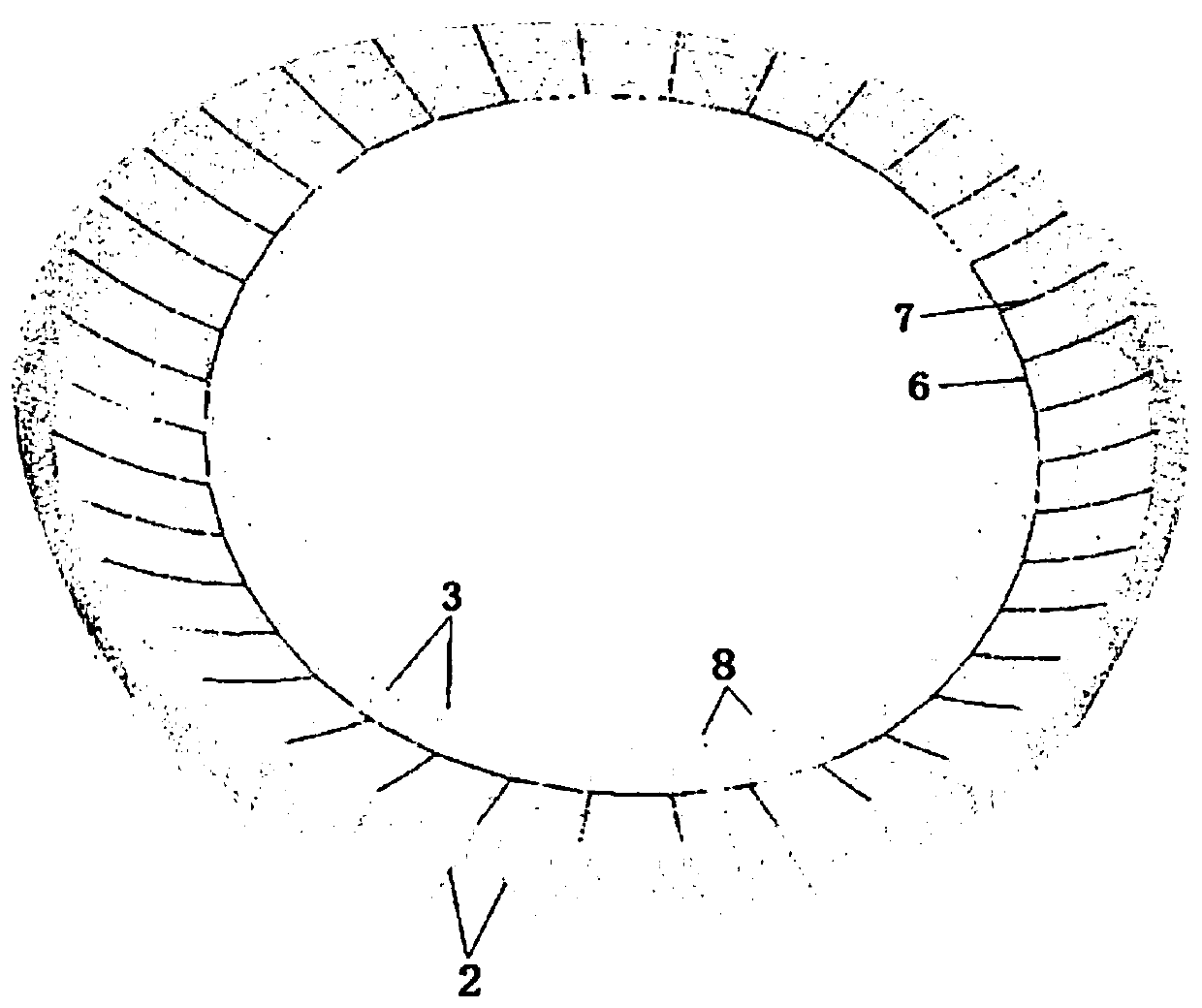

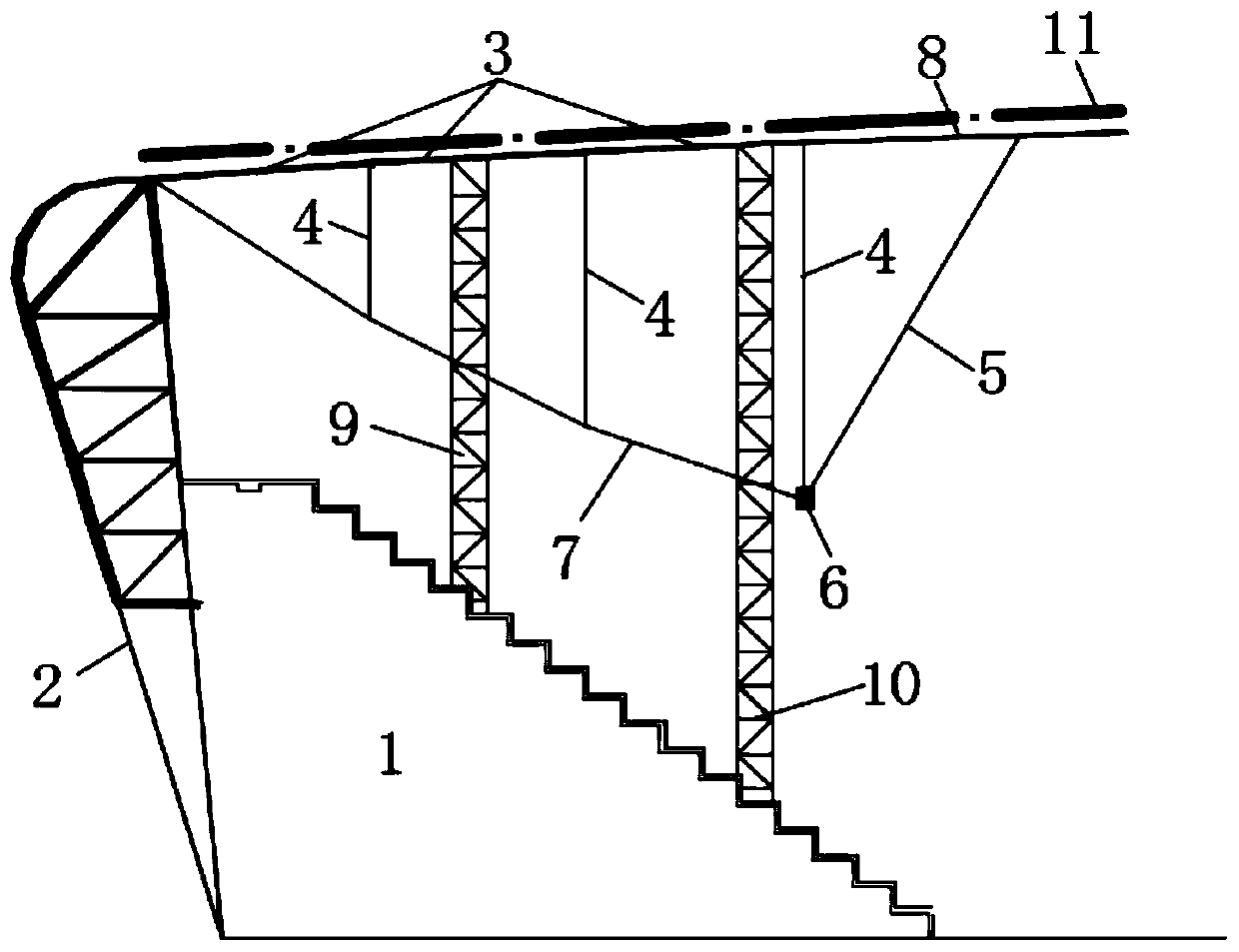

[0027] Embodiment: A construction method of a ring-shaped cable-supported grid structure in which the upper grid participates in balancing the pretension of the cables, and the method includes the following steps:

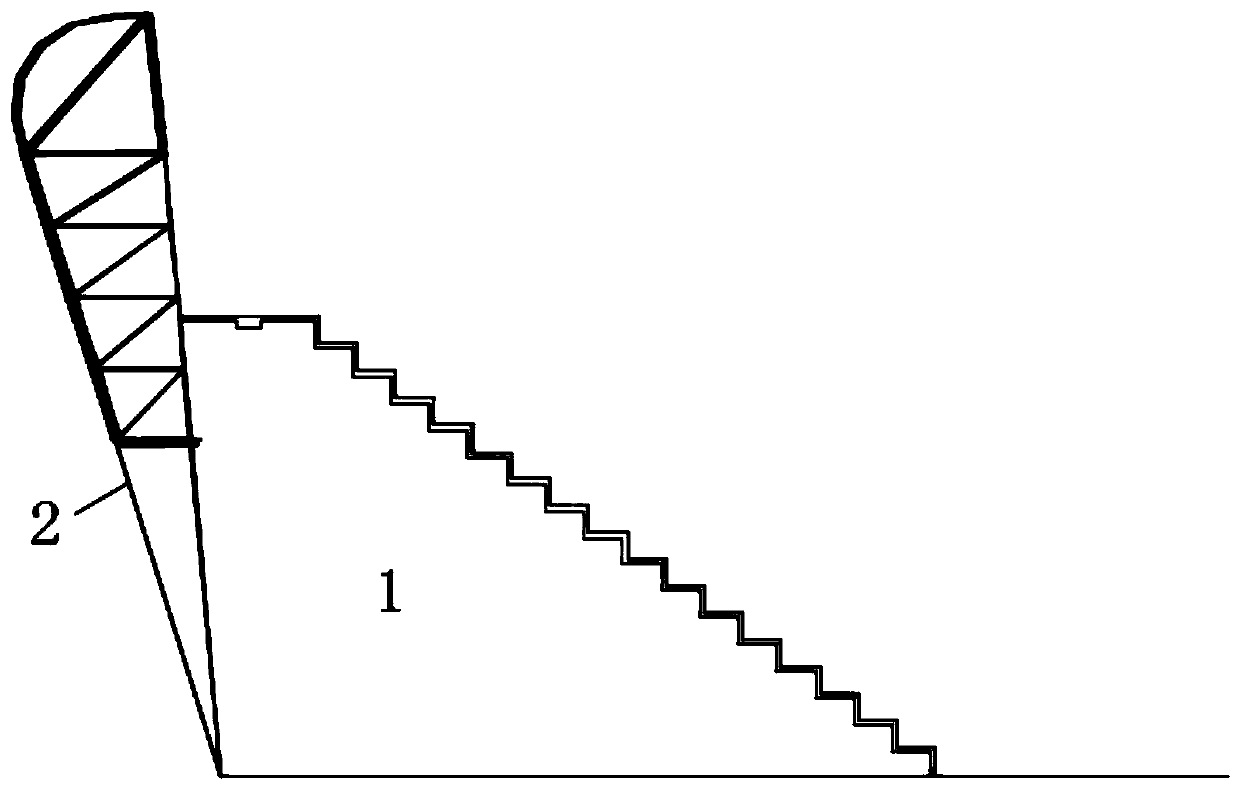

[0028] Step 1: Install the pillars and outer ring;

[0029] Step 2: Install the tire frame, that is, install the tire frame under the main grid that can be both compressed and tensioned, and a horizontal sliding device is installed on the top of the tire frame; the horizontal displacement of the upper grid is not restricted;

[0030] Step 3: Install the main grid and corresponding struts on the tire frame, and the tire frame is under pressure at this time;

[0031] Step 4: Install and tension the lower cable net. At this time, the tire frame is under tension and there is a horizontal relative slippage between the top and the main grid;

[0032] Step 5: Install the cantilever grid and corresponding struts;

[0033] Step 6: Remove the tire frame after installing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com