Main cone pad selecting device and method

A technology of pad selection and rotary drive device, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of scrapping parts, affecting the height of the top of the main cone assembly 10, not meeting requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

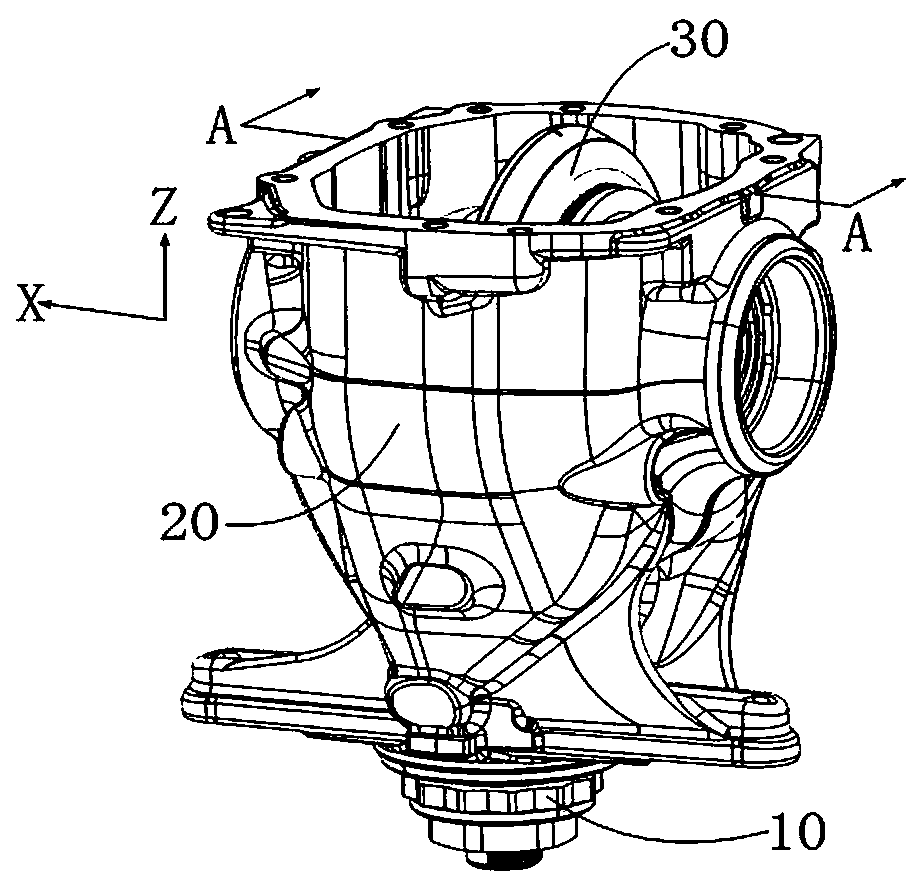

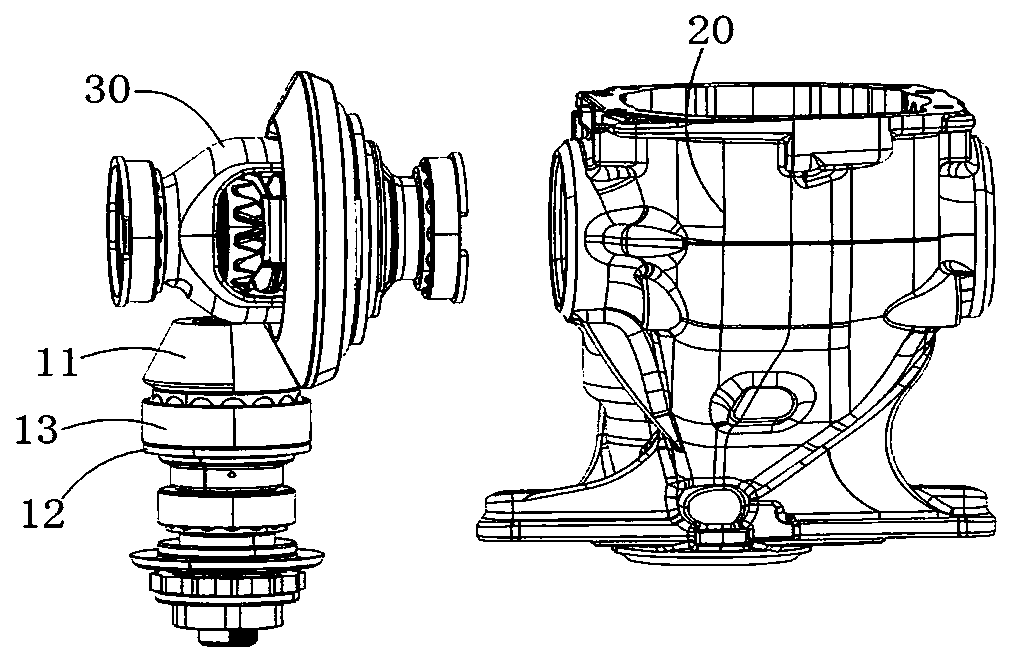

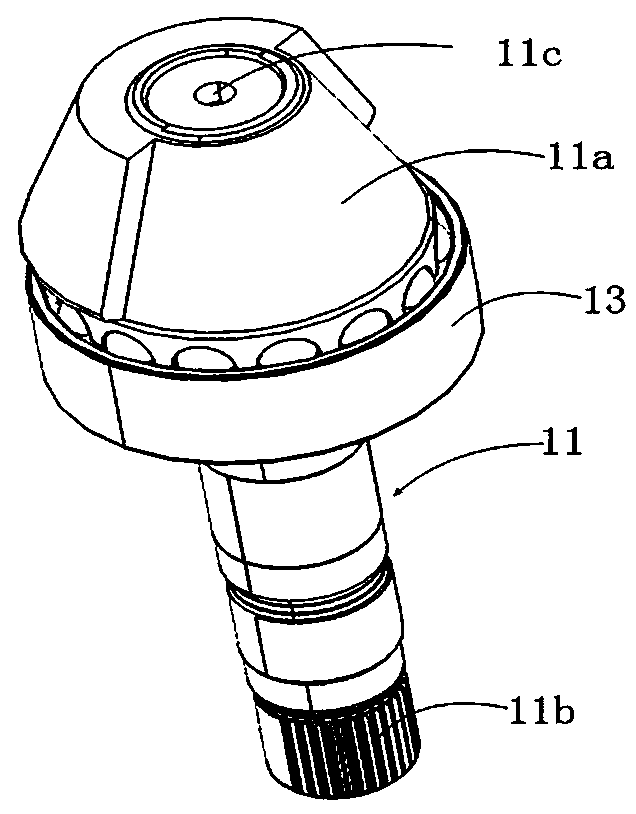

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] In addition, the upper mentioned in the embodiments of the present invention is the direction shown by Z in the drawings, and the direction opposite to the Z direction is the lower; the heights mentioned in the embodiments of the present invention all refer to the The extension length in the up and down direction; the higher mentioned in the embodiments of the present invention means that the position is relatively above, and the lower means that the position is relatively below.

[0042] If there are descriptions involving "first", "second", etc. in the embodiments of the present invention, the descriptions of "first", "second", etc. Significance or implicitly indicates the number of technical features indicated.

[0043] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com